Polyurethane grouting micro-pile with pile bag and its construction method and application method

An application method and technology of micro-pile, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of production and operation activities, waste of cement slurry, large number of coarse particles, etc., to achieve green environmental protection, pollution-free performance, and fast construction Simple and low environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

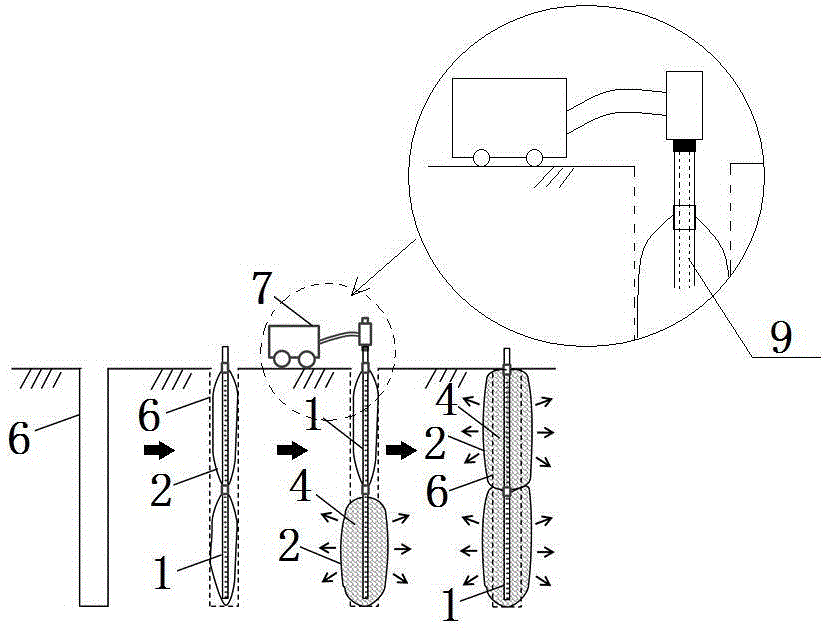

[0035] Embodiment: This embodiment specifically relates to a polyurethane grouting micro pile with a pile bag and its construction method and application method. Slope and other reinforcement works.

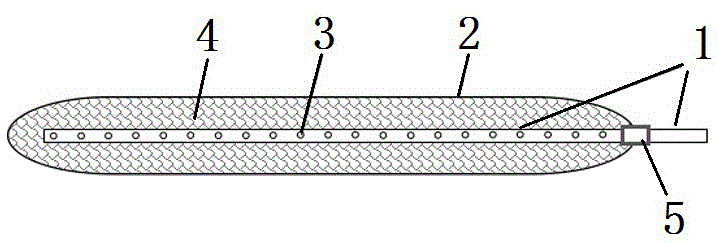

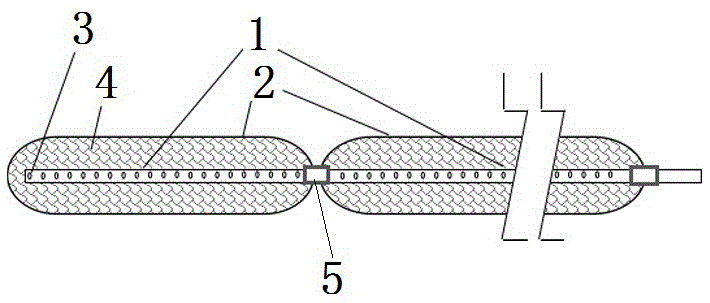

[0036] Such as figure 1 As shown, the micropile in this embodiment is installed in the soil in a vertical or oblique posture, which includes a grouting outer tube 1, a flexible pile bag 2 set outside the grouting outer tube 1, and a pile bag 2 filled in the grouting outer tube 1 and the polyurethane foam 4 inside the flexible pile bag 2, the mouth of the flexible pile bag 2 is fastened and fixed with the outer wall of the mouth of the grouting outer pipe 1 by a collar 5. Wherein, the grouting outer pipe 1 can be a kind of in steel pipe, PVC pipe, ABS pipe or sleeve valve pipe, and it is positioned at the pipe wall part in the flexible pile bag 2 and has grouting hole 3; Flexible pile bag 2 can be One of geotextile bags, cloth bags, plastic sleeves, rubber sleeves, nylon fiber b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com