Sodium yttrium borate, sodium yttrium borate nonlinear optical crystal as well as preparation method and application of sodium yttrium borate nonlinear optical crystal

A technology of nonlinear optics and sodium yttrium borate, applied in nonlinear optics, optics, crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

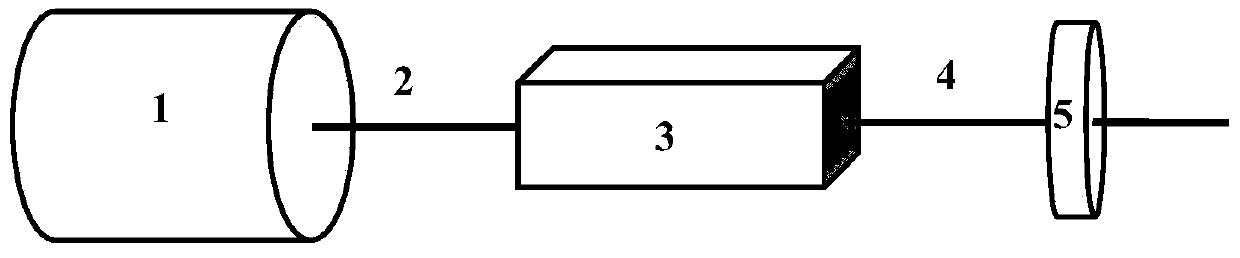

Method used

Image

Examples

Embodiment 1

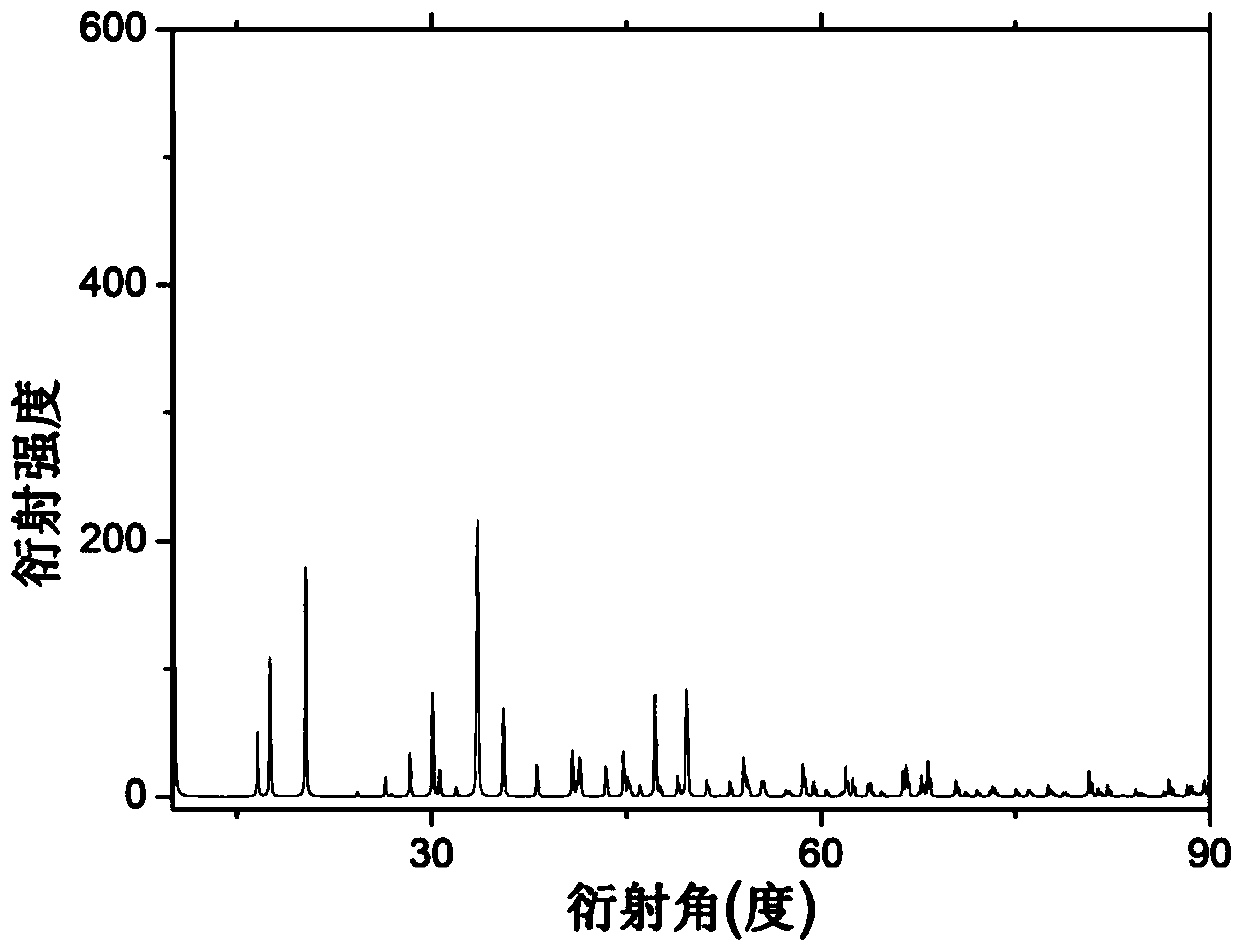

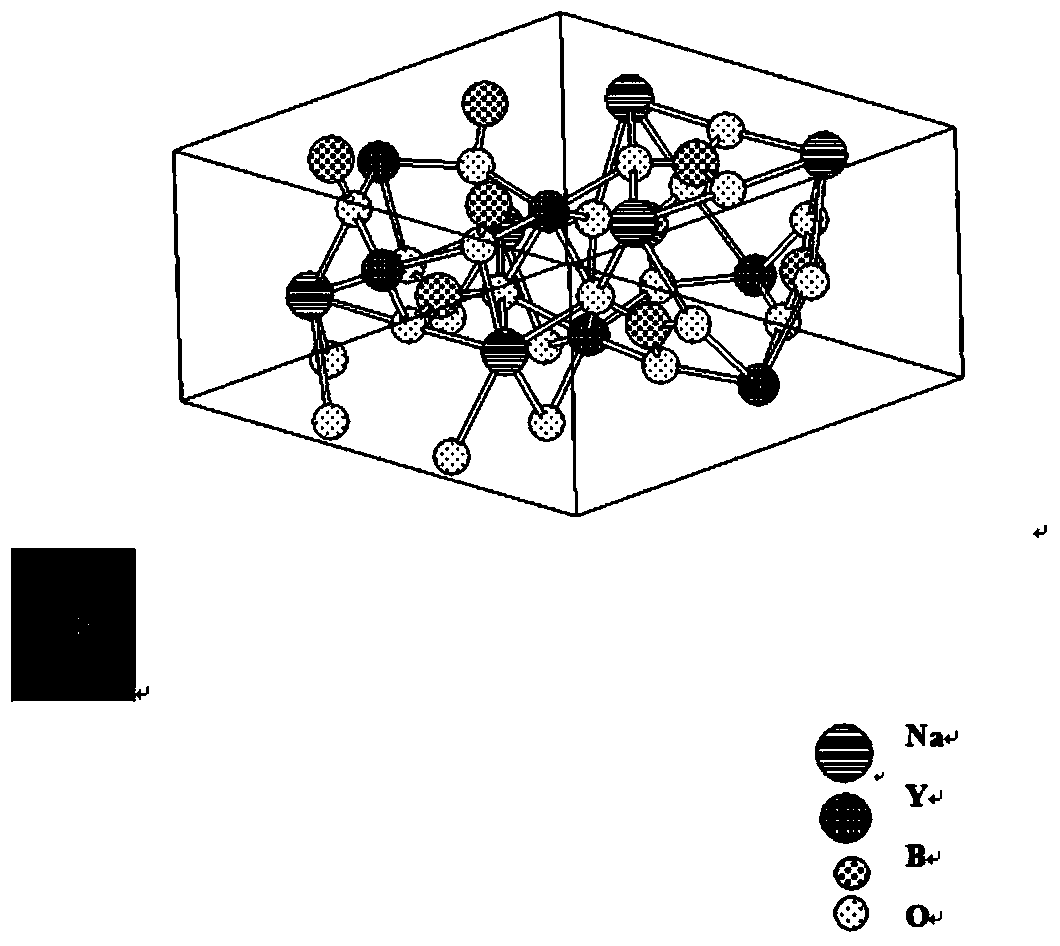

[0040] Embodiment 1: prepare powdery Na 3 Y 3 (BO 3 ) 4 compound

[0041] Prepared by solid phase reaction method, the reaction equation used is 3Na 2 O+3Y 2 o 3 +4B 2 o 3 =2Na 3 Y 3 (BO 3 ) 4 ;

[0042] The proportioning ratio of the above three reagents: Na 2 O=5.780g (0.09mol); Y 2 o 3 =20.324g (0.09mol); B 2 o 3 =8.354g (0.12mol);

[0043] The specific preparation steps are: weigh the reagents according to the above doses, put them in a mortar, grind and mix them carefully, then put them into a Φ50mm×50mm crucible, compact them, put them into a muffle furnace, and Heat up at a rate of 50°C / h to 500°C for pre-firing, keep it warm for 24 hours and then cool down. After cooling, take out the sample and re-grind and mix it evenly, then put it in a crucible for compaction, and sinter in a muffle furnace at 1100°C for 24 hours. You can take it out in the middle Grind 1-2 times; after cooling, take out the crucible, crush and grind in a mortar to obtain powdere...

Embodiment 2

[0044] Embodiment 2: prepare powdery Na 3 Y 3 (BO 3 ) 4 compound

[0045] Prepared by solid phase reaction method;

[0046] The reaction equation adopted is: 3Na 2 CO 3 +3Y 2 o 3 +8H 3 BO 3 =2Na 3 Y 3 (BO 3 ) 4 +3CO 2 ↑+12H 2 O↑

[0047] The proportioning ratio of the above three reagents: Na 2 CO 3 =9.539g (0.09mol); Y 2 o 3 =20.324g (0.09mol); H 3 BO 3 =14.839g (0.24mol);

[0048] The specific preparation steps are: weigh the reagents according to the above doses, put them in a mortar, grind and mix them carefully, then put them into a Φ50mm×50mm crucible, compact them, put them into a muffle furnace, and Raise the temperature at a rate of 30°C / h to 500°C for pre-firing, keep it warm for 48 hours, take out the sample after cooling, grind and mix evenly, then put it in a crucible for compaction, sinter in a muffle furnace at 800°C for 48 hours, take it out and grind it for 1~ 2 times. After cooling, the crucible is taken out, crushed and ground in a m...

Embodiment 3

[0049] Embodiment 3: prepare powdery Na 3 Y 3 (BO 3 ) 4 compound

[0050] Prepared by solid phase reaction method;

[0051] The reaction equation adopted is as follows:

[0052] 12NaNO 3 +6Y 2 o 3 +16H 3BO 3 =4Na 3 Y 3 (BO 3 ) 4 +12NO 2 ↑+24H 2 O↑+3O 2 ↑

[0053] The ratio of the above three reagents: NaNO 3 =15.300g (0.18mol); Y 2 o 3 =40.648g (0.18mol); H 3 BO 3 =14.839g (0.24mol).

[0054] The specific preparation steps are: weigh the reagents according to the above doses, put them in a mortar, grind and mix them carefully, then put them into a Φ50mm×50mm crucible, compact them, put them into a muffle furnace, and Raise the temperature at a rate of 40°C / h to 500°C for pre-firing, and keep it warm for 36 hours. After cooling, take out the sample and re-grind and mix it, then put it in a crucible for compaction, sinter in a muffle furnace at 900°C for 36 hours, take it out and grind it for 1~ 2 times. After cooling, the crucible is taken out, crushed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com