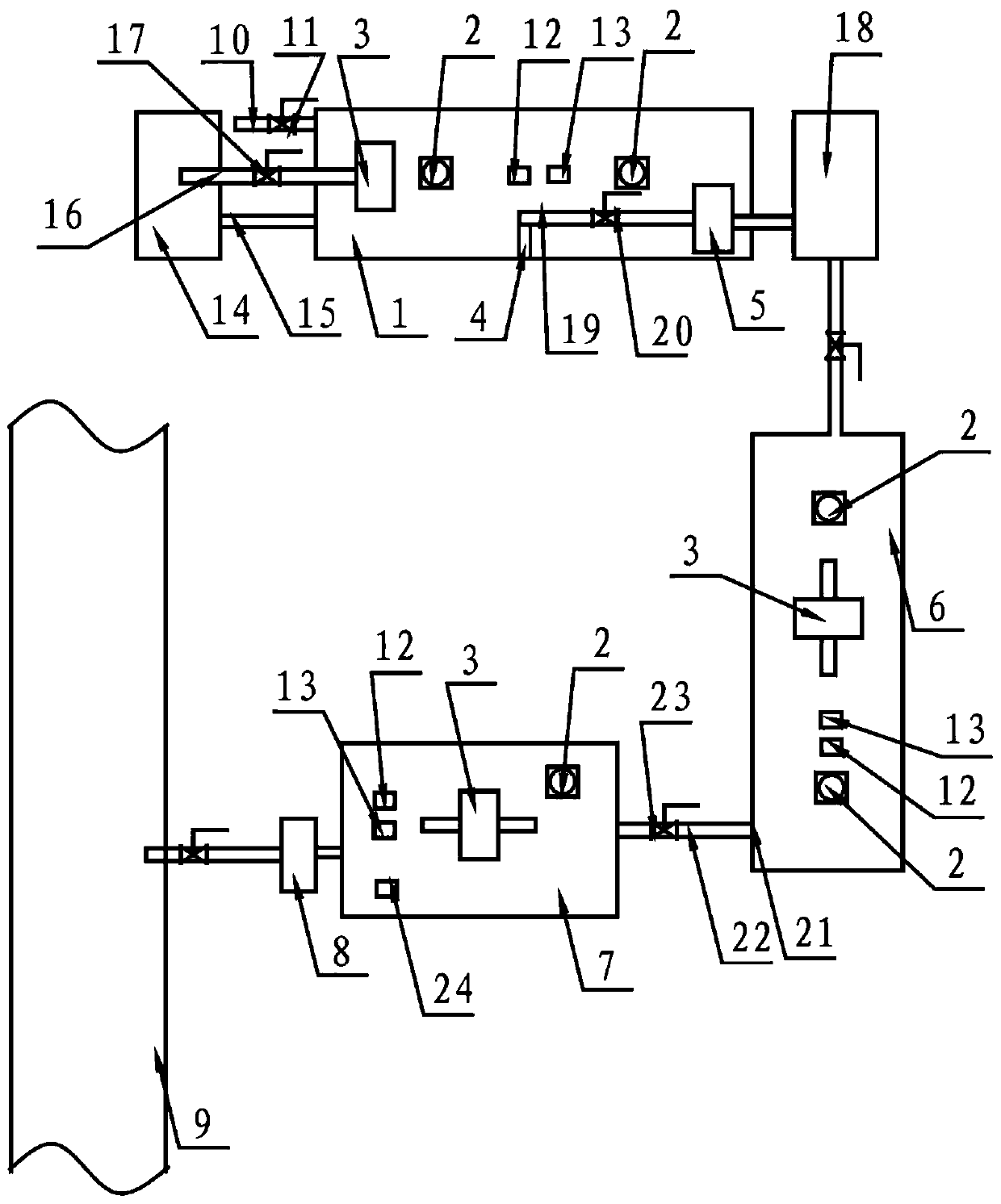

Slivering solution pre-dissolving process

A technology of pre-dissolving and silver-plating solution, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems affecting the uniformity of silver plating, the concentration cannot be improved, and the rise of silver ions, etc., so as to save raw materials for silver plating, Uniform thickness and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] one. Dissolving (preparing a silver-containing solution with a silver ion concentration of 80g / L)

[0043] Silver cyanide and potassium cyanide are used as raw materials; the volume of the prepared solution is 700L.

[0044] A. Calculate the required dosage of each drug according to the preparation amount and preparation concentration.

[0045] According to the calculation, 70KG of silver cyanide and 35KG of potassium cyanide are needed.

[0046] B. Add about 500L of pure water into the dissolving tank, then add 35KG of potassium cyanide, circulate the liquid medicine and raise the temperature (set the temperature at 60°C). Circulate for two hours until the potassium cyanide is completely dissolved.

[0047] C. Add 70KG silver cyanide to the solution, add pure water to 700L, and circulate the solution for 24 hours until the silver cyanide is completely dissolved.

[0048] D. Laboratory personnel take samples and analyze, and adjust the silver ion concentration to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com