Preparation method of decorating protective coating for CrNx-based component gradient transition

A composition gradient, protective coating technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problem of wear resistance, coating appearance smoothness, color uniformity and stability decline, Discontinuity and other problems, to achieve the effect of uniform appearance and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the following embodiments, x (x≤1) in the CrNx-based gradient transition layer refers to the stoichiometric ratio of N and Cr.

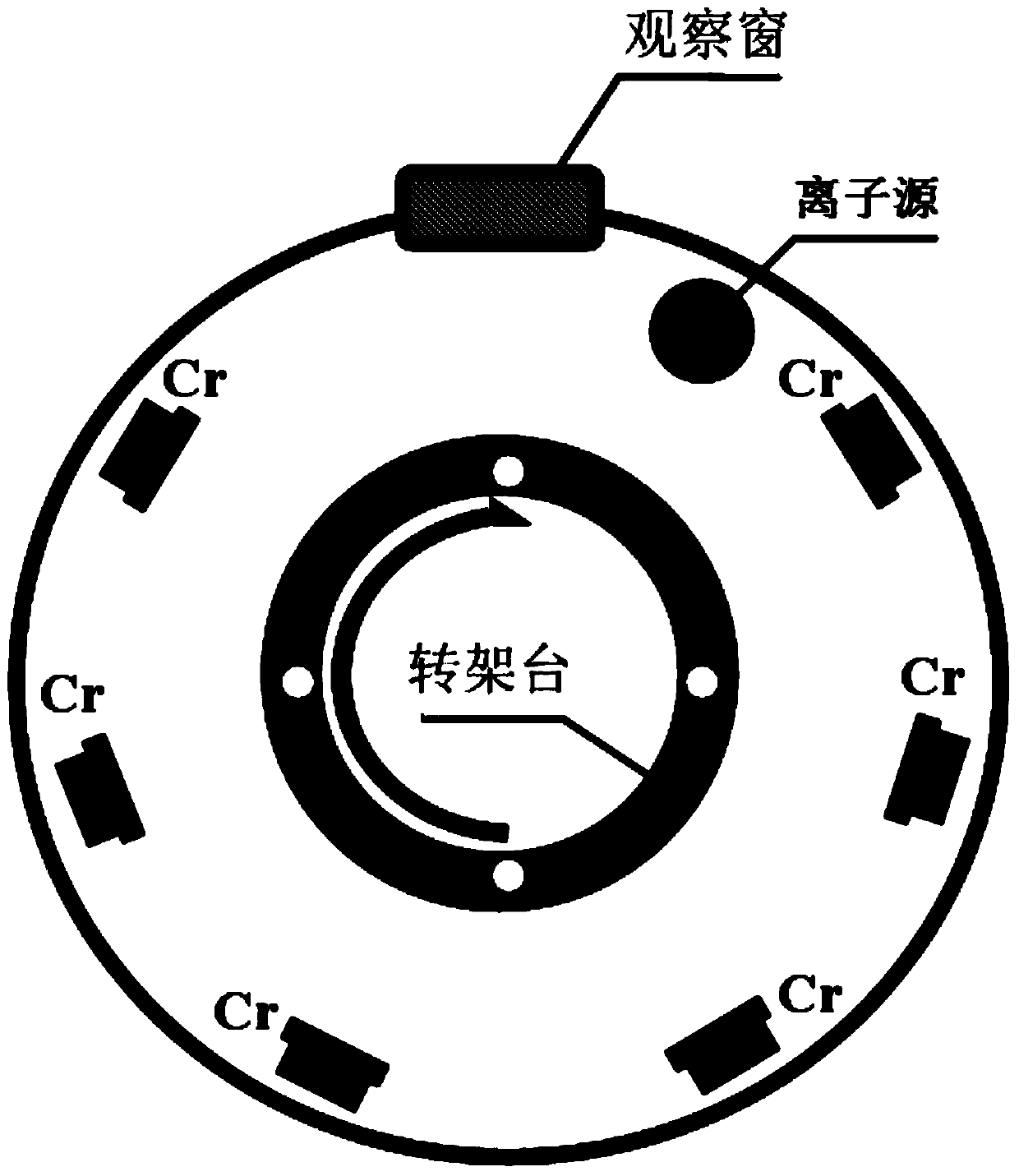

[0013] According to the technical scheme of the present invention, the preparation method of the decorative protective coating with gradient transition of CrNx-based composition adopts three pairs of planar Cr targets as the source of corresponding Cr elements, and the three pairs of planar Cr targets are evenly installed in the ion source to enhance magnetron sputtering ion On the inner wall of the coating equipment, the sputtering rate of the above three pairs of planar Cr targets is controlled by adjusting the current of the intermediate frequency pulse power supply; an anode layer gas ion source is used to increase the ionization rate of the gas and the energy of the reaction particles; high-purity Ar is used As target sputtering gas; using high-purity N 2 As a reaction gas, after passing through the gas ion source of the anode layer, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com