A monitoring operation vacuum furnace for anti-corrosion vacuum pump sewage liquid purification

A vacuuming and vacuum furnace technology, applied in heat treatment process control, heat treatment equipment, quenching devices, etc., can solve the problems of serious heat dissipation, oil splashing, and the temperature cannot reach thermal insulation, so as to reduce the loss of heat energy and isolate the loss of heat energy. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

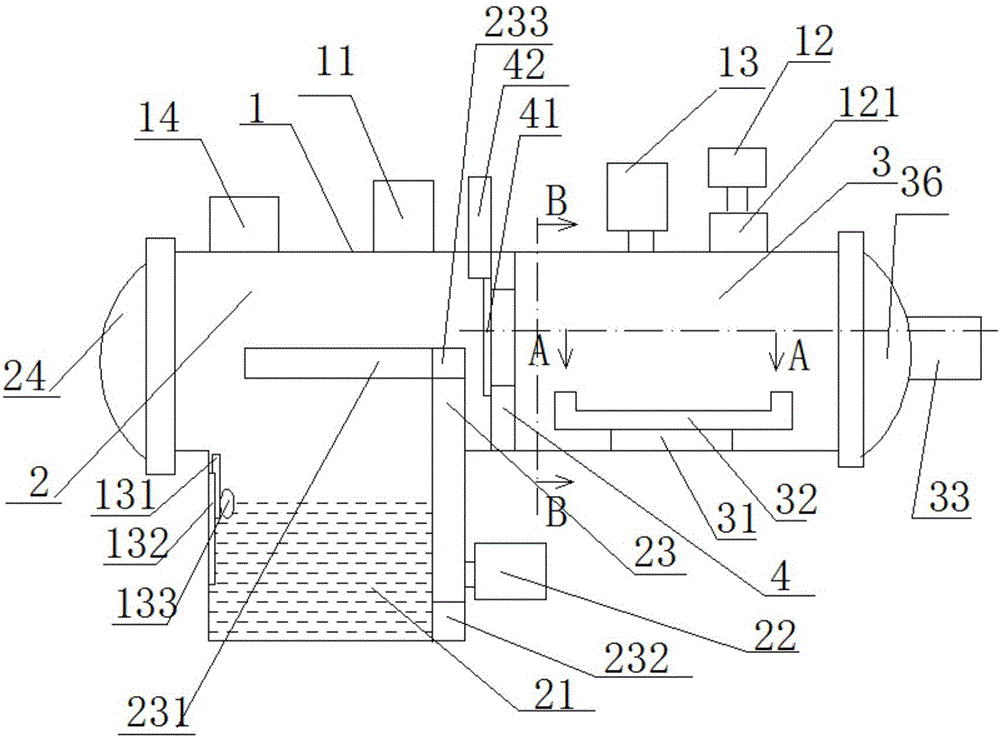

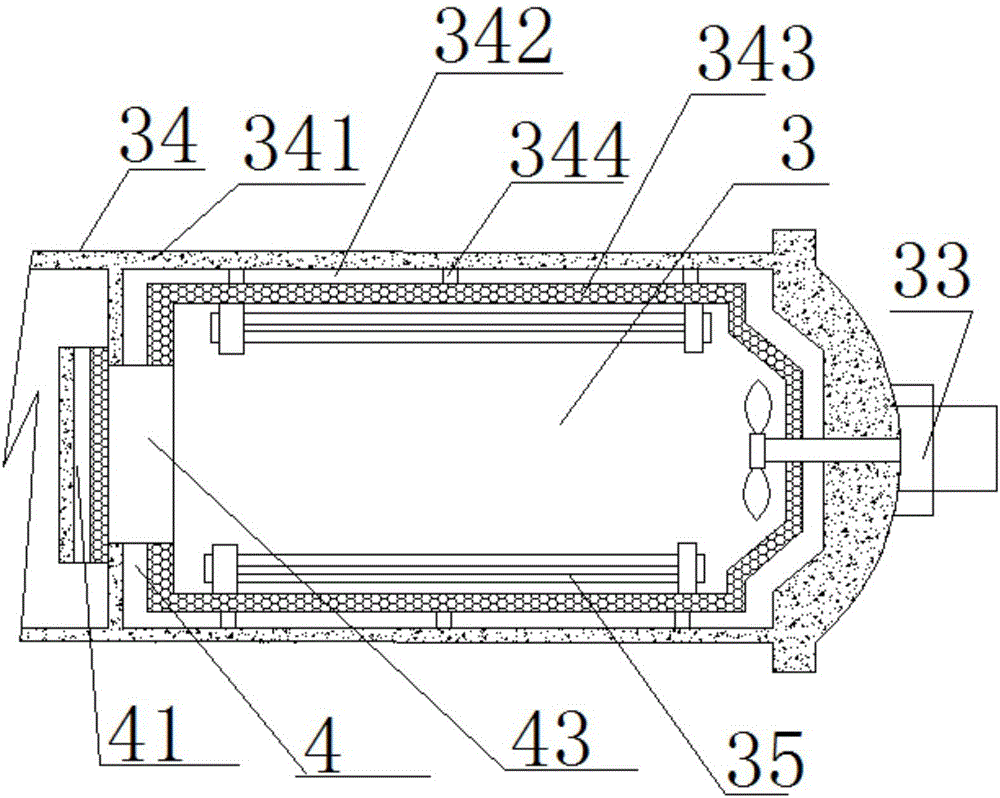

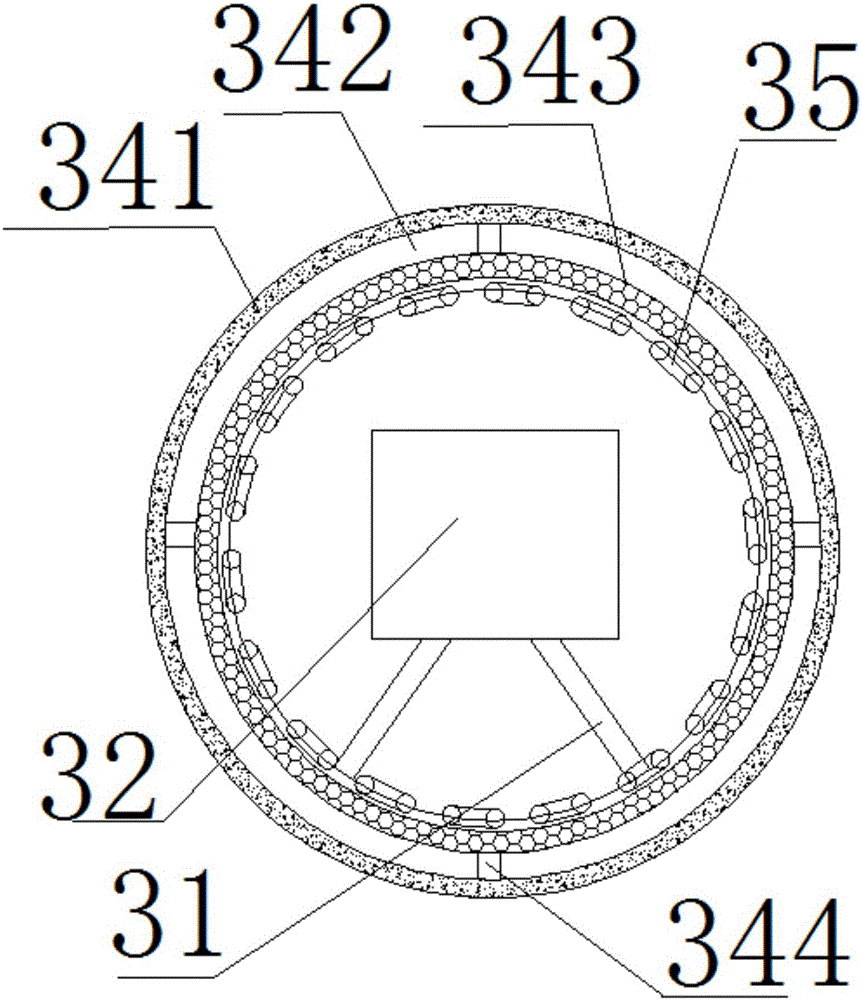

[0033] The monitoring operation vacuum furnace of a kind of anticorrosion vacuumizing machine blowdown liquid type purification of the present embodiment, such as Figure 1-5 As shown, it includes a furnace shell, and a cooling chamber and a heating chamber are arranged inside the furnace shell, and the cooling chamber and the heating chamber are separated by a partition wall; the cooling chamber is sequentially provided with gas quenching chambers from top to bottom. Chamber and oil quenching chamber, while the upper part of the gas quenching chamber is provided with an inflatable rapid cooling mechanism, while the lower part of the oil quenching chamber is provided with an oil quenching oil tank, and the side of the cooling chamber opposite to the heating chamber is provided with a cooling chamber furnace door; The heating chamber is provided with a heating chamber platform, the material frame is placed on the heating chamber platform, and at the same time, one or more heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com