Preparation method for virgin pulp aromatic vinegar

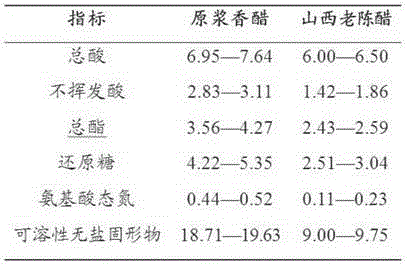

A technology of puree balsamic vinegar and puree white grain vinegar, which is applied in the preparation of vinegar and other directions, can solve problems such as being unfavorable to shortening the capital turnover of enterprises, disadvantageous to the improvement of production efficiency of enterprises, and improving the utilization rate of equipment, so as to achieve a strong aroma and high quality. Rich, bright color, the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of puree balsamic vinegar, comprising the steps of:

[0048] (1) Preparation of puree white fermented grain vinegar

[0049] ①Raw material selection and processing

[0050] Select sorghum with full grains and no mildew, crushed into 4 to 6 petals, add 70 kg of water to 100 kg of raw materials, and mix thoroughly to make the raw materials absorb water evenly and adequately. Afterwards, the moistened raw materials were added into a high-pressure cooking container by high-pressure steam method, and cooked at 121°C and 0.11Mpa for 1 hour.

[0051] ② mix song

[0052] Crush Daqu into pieces, then grind it into fine powder, add 63kg of koji evenly to the raw materials cooled to 21°C according to the ratio of 100kg of raw materials, and fully stir.

[0053] ③Alcoholic fermentation

[0054] After the raw materials and Daqu are evenly mixed, transfer them to the alcohol fermentation tank, add 80 kg of cooling water, control the ratio of material to water...

Embodiment 2

[0080] A preparation method of puree balsamic vinegar, comprising the steps of:

[0081] (1) Preparation of puree white fermented grain vinegar

[0082] ①Raw material selection and processing

[0083] Select sorghum with full granules and no mildew, crushed into 4-6 petals, add 75 kg of water to 100 kg of raw materials for moistening, and fully stir to make the raw materials absorb water evenly and adequately. Afterwards, the moistened raw materials were added into a high-pressure cooking container by high-pressure steam method, and cooked at 121°C and 0.11Mpa for 1 hour.

[0084] ② mix music

[0085] The Daqu is crushed into pieces, and then ground into fine powder, and the ratio of 61 kg of koji mixed with 100 kg of raw materials is evenly added to the raw materials cooled to 20 ° C, and fully stirred.

[0086] ③Alcoholic fermentation

[0087] After the raw materials and Daqu are evenly mixed, transfer them to the alcohol fermentation tank, add 85 kg of cooling water, co...

Embodiment 3

[0113] A preparation method of puree balsamic vinegar, comprising the steps of:

[0114] (1) Preparation of puree white fermented grain vinegar

[0115] ①Raw material selection and processing

[0116] Select sorghum with full granules and no mildew, crushed into 4-6 petals, add 72 kg of water to 100 kg of raw materials for moistening, and fully stir to make the raw materials absorb water evenly and adequately. Afterwards, the moistened raw materials were added into a high-pressure cooking container by high-pressure steam method, and cooked at 121°C and 0.11Mpa for 1 hour.

[0117] ② mix song

[0118] The Daqu is crushed into pieces, and then ground into fine powder, and the ratio of 62 kg of koji mixed with 100 kg of raw materials is evenly added to the raw materials cooled to 22 ° C, and fully stirred.

[0119] ③Alcoholic fermentation

[0120] After the raw materials and Daqu are evenly mixed, transfer them to the alcohol fermentation tank, add 83 kg of cooling water, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com