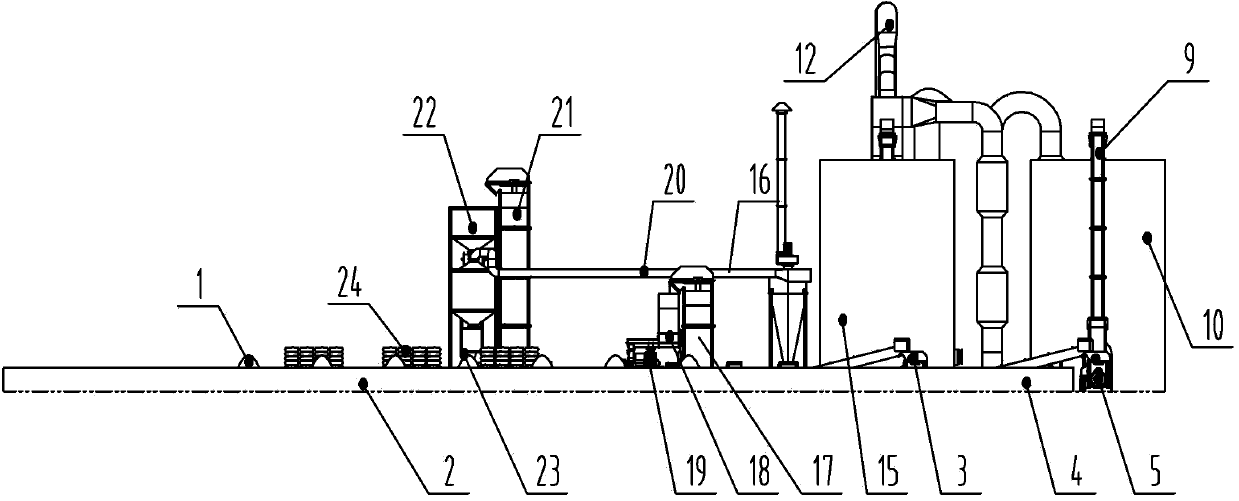

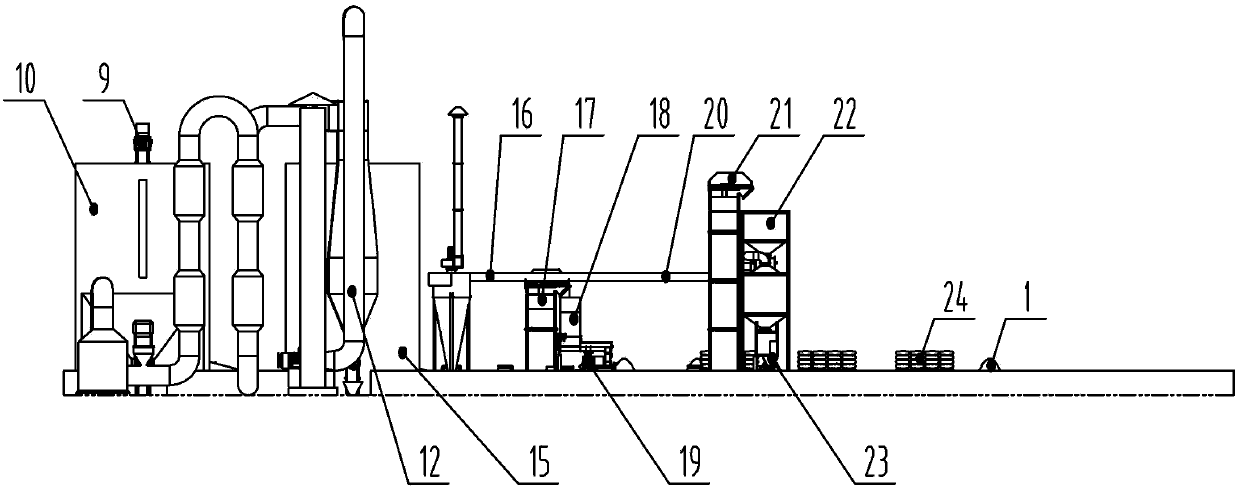

Biomass particle forming production line and method

A biomass pellet and assembly line technology, applied in biofuel, waste fuel, feed and other directions, can solve the problems of unsustainable machine work, waste of resources and environment, low production efficiency, etc., and achieve low production cost, increase output, and low production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

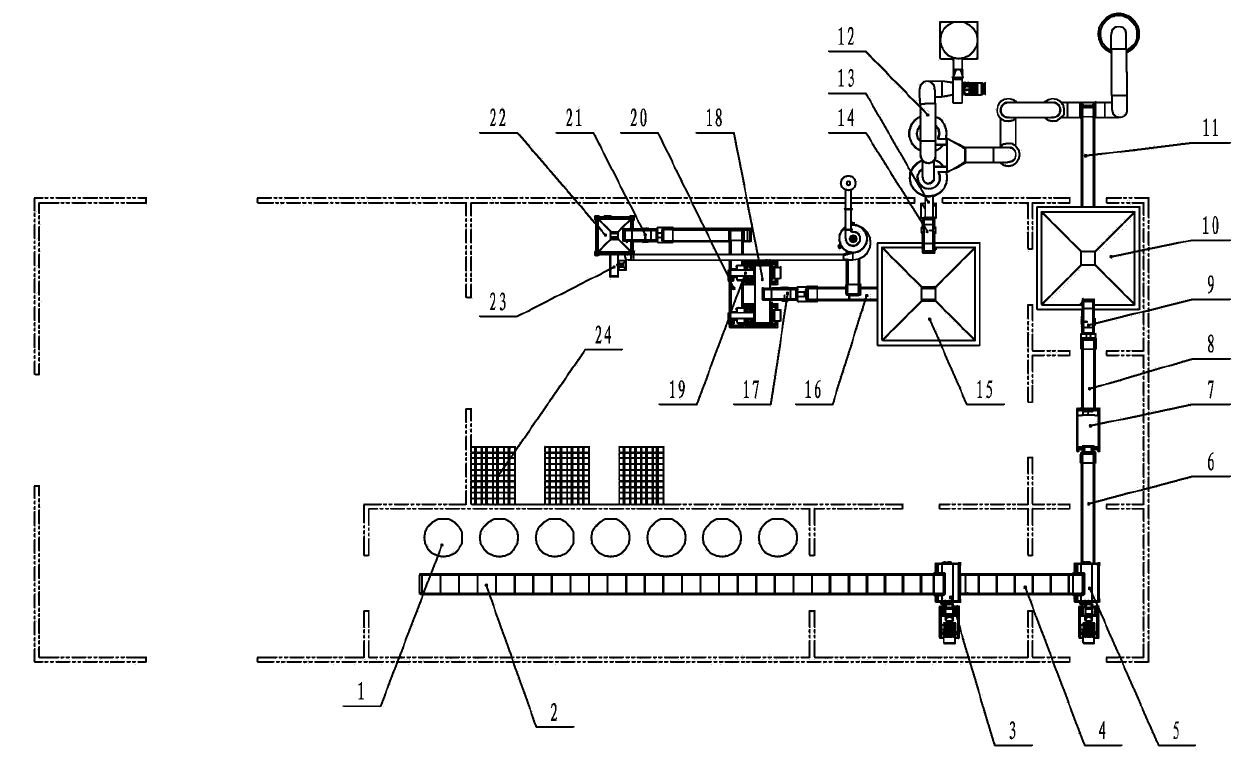

[0031] Utilize the shaping method of embodiment 1 assembly line, comprise the following steps:

[0032] (1) Turn on the master control system and transport the raw materials to the press for pressing;

[0033] (2) The squeezed raw materials pass through the pulverizer and material selection screen in turn, and then enter the transfer bin through the elevator;

[0034] (3) After the raw materials in the transfer bin are dried by the drying device, they enter another transfer bin through the elevator, and then the raw materials enter the granulator through the distribution bin for molding; Iron removal;

[0035] (4) The obtained pellets are transported to the cooling package through the hoist, and the finished product is obtained after packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com