Polyolefin microporous air-permeable film and preparation method thereof

The technology of polyolefin and breathable film is applied in the field of polyolefin microporous breathable film and its preparation to achieve the effects of reducing the steps of sewing and gluing and sealing, improving the process interval and achieving great economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

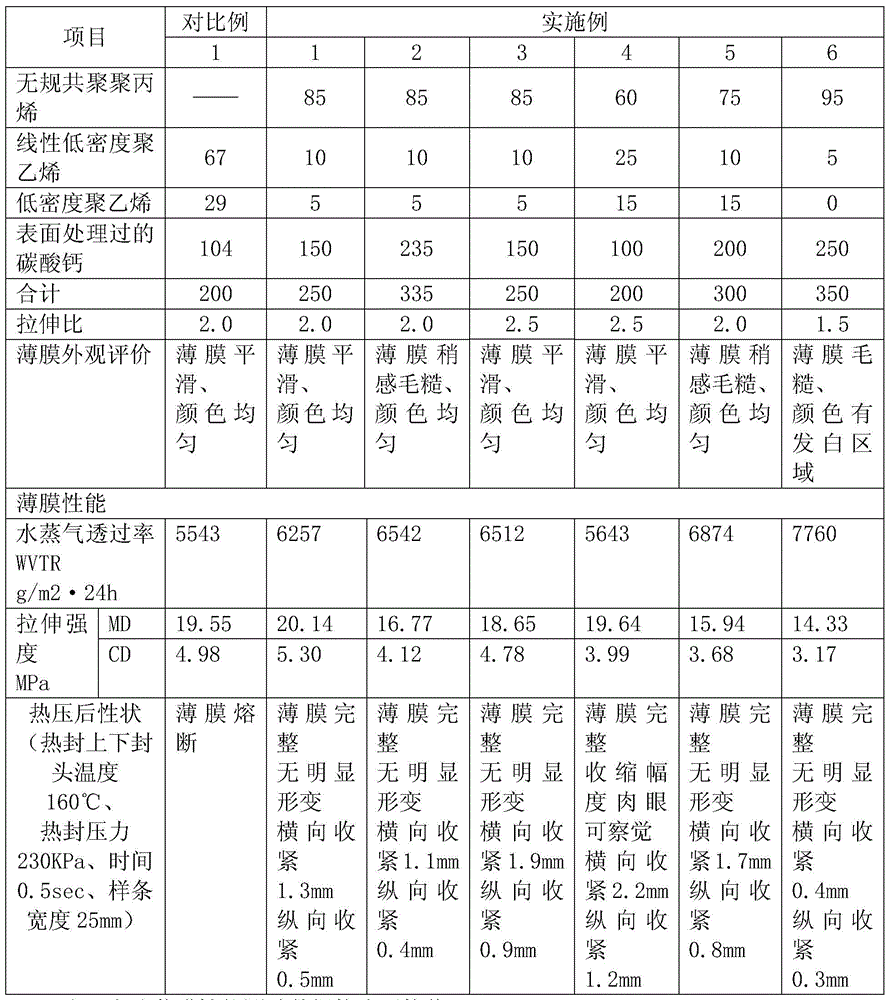

Embodiment 1

[0028] The polyolefin microporous air-permeable film involved in this embodiment is made of polyolefin substrate filled surface with calcium carbonate filler treated by coating method, and then extruded, cast, stretched, heat-set and film-forming process. In terms of components, it consists of random copolymerized polypropylene, linear low-density polyethylene, low-density polyethylene, and calcium carbonate filler blends whose surface has been treated by coating methods; among them, the melt index of random copolymerized polypropylene 0.5~10g / 10min, density 0.890~0.915g / cm 3 ;The melt index of linear low density polyethylene is 1~4g / 10min, and the density is 0.915~0.940g / cm 3 ;The melt index of low-density polyethylene is 2-7g / 10min, and the density is 0.910-0.925g / cm 3 Concrete consumption of each component is as shown in Table 1.

[0029] The preparation process of the polyolefin microporous air-permeable membrane of this embodiment specifically includes the following ste...

Embodiment 2

[0035] The polyolefin microporous air-permeable film and its preparation method involved in this embodiment are the same as those in Embodiment 1, except that:

[0036] 1. The dosage of components is different, see Table 1 for details;

[0037]2. The air-permeable particles are extruded and melted by a casting extruder, and the melt temperature is kept at 245-250°C;

[0038] 3. The heat setting temperature is controlled at 85°C;

[0039] 4. Perform uniaxial two-step stretching on the film, and the stretching ratio is controlled at 2.0.

[0040] Relevant performance tests were carried out on the prepared microporous breathable membrane with a basis weight of 55 gsm, and the results are shown in Table 1.

Embodiment 3

[0042] The polyolefin microporous air-permeable film and its preparation method involved in this embodiment are the same as those in Embodiment 1, except that:

[0043] 1. The dosage of components is different, see Table 1 for details;

[0044] 2. The air-permeable particles are extruded and melted by a casting extruder, and the melt temperature is kept at 250-255°C;

[0045] 3. The heat setting temperature is controlled at 70°C;

[0046] 4. Perform uniaxial two-step stretching on the film, and the stretching ratio is controlled at 2.5.

[0047] Relevant performance tests were carried out on the prepared microporous breathable membrane with a basis weight of 55 gsm, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com