A Method for Reducing the Edge Positioning Error of Optical Proximity Correction for Critical Dimensions

A technology of optical proximity correction and positioning error, which is applied to the photoplate process of optics and pattern surface, and the original for photomechanical processing, etc. It can solve problems such as EPE error, improve the process range, reduce manual debugging time, Effect of Small Edge Positioning Errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

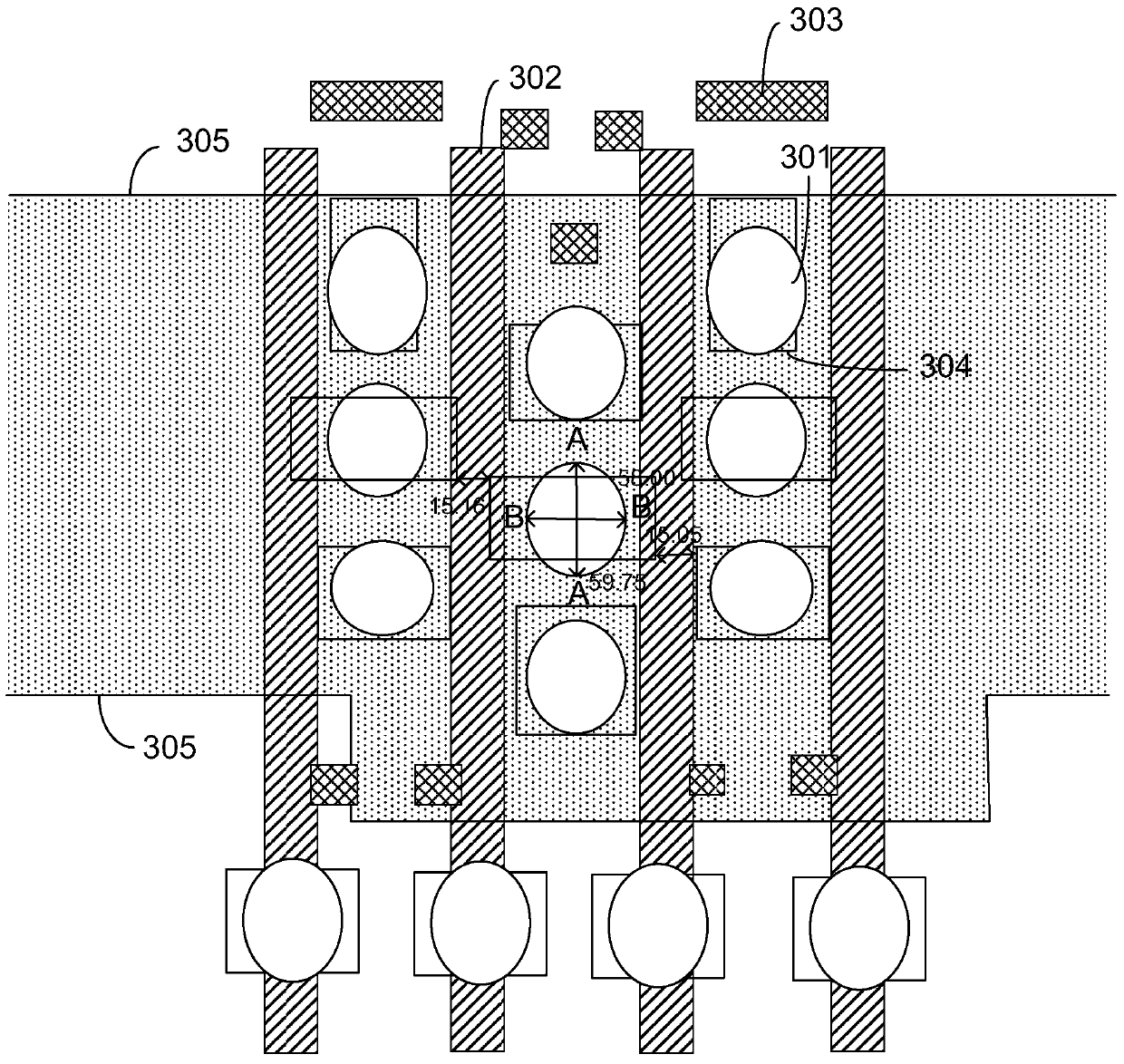

[0030] The embodiments of the present invention will now be described in detail with reference to the drawings. Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are shown in the accompanying drawings. Wherever possible, the same signs will be used in all the drawings to indicate the same or similar parts. In addition, although the terms used in the present invention are selected from well-known and public terms, some of the terms mentioned in the specification of the present invention may be selected by the applicant according to his or her judgment. The detailed meanings are described herein. In the relevant part of the description. In addition, it is required to understand the present invention not only through the actual terms used, but also through the meaning contained in each term.

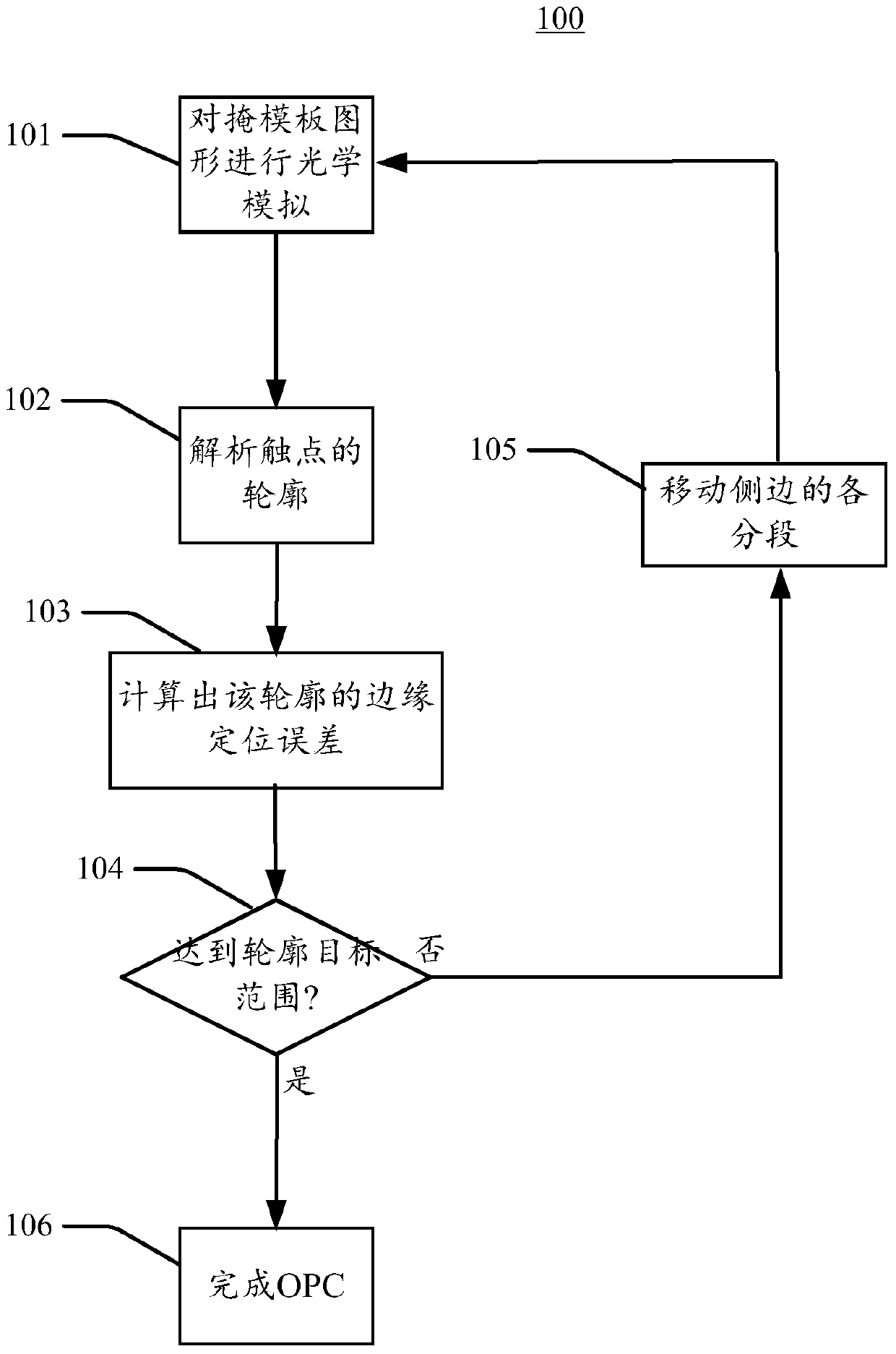

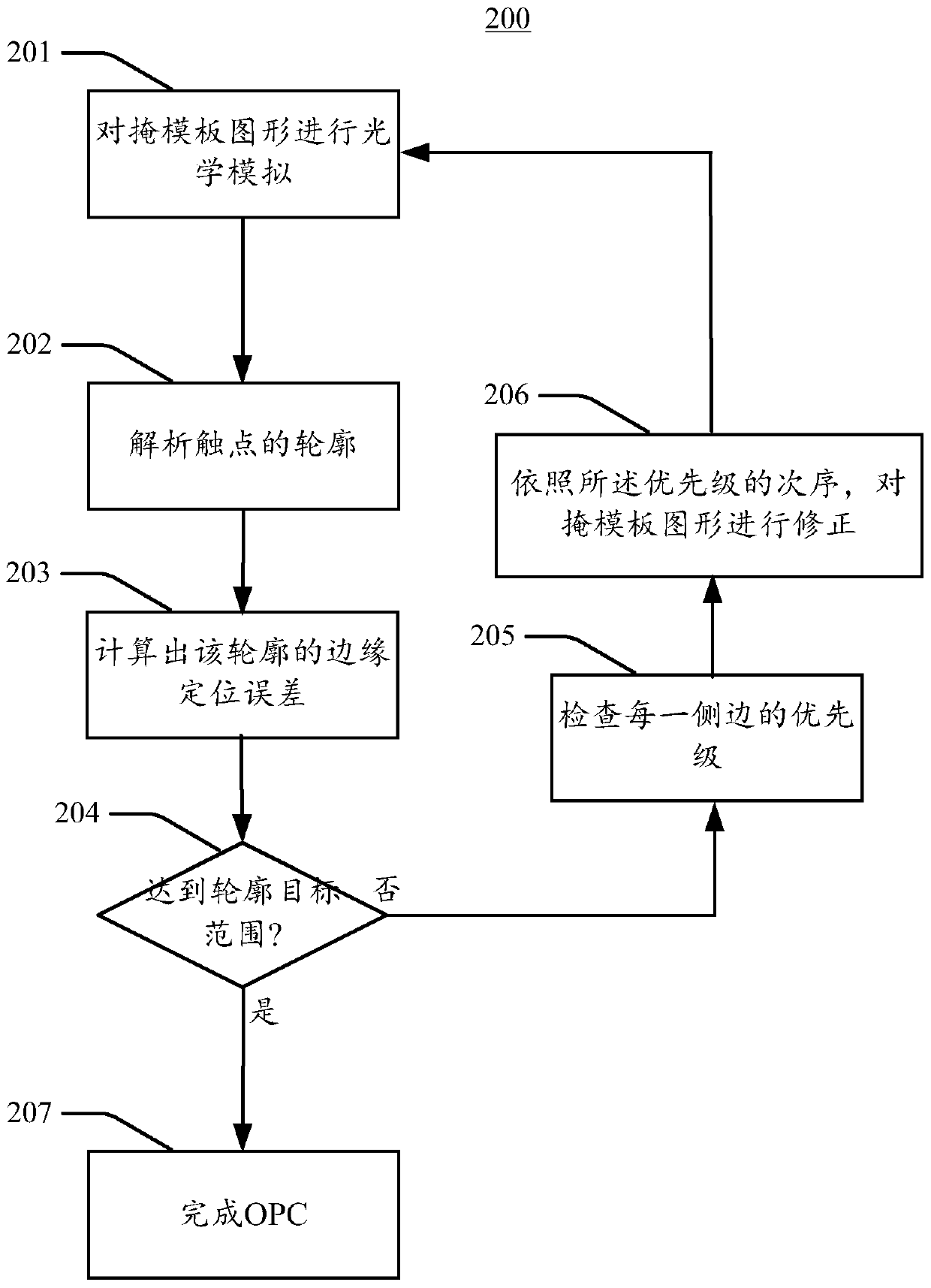

[0031] figure 2 A flowchart of the method according to the invention is shown. Such as figure 2 As shown, the method 200 for re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com