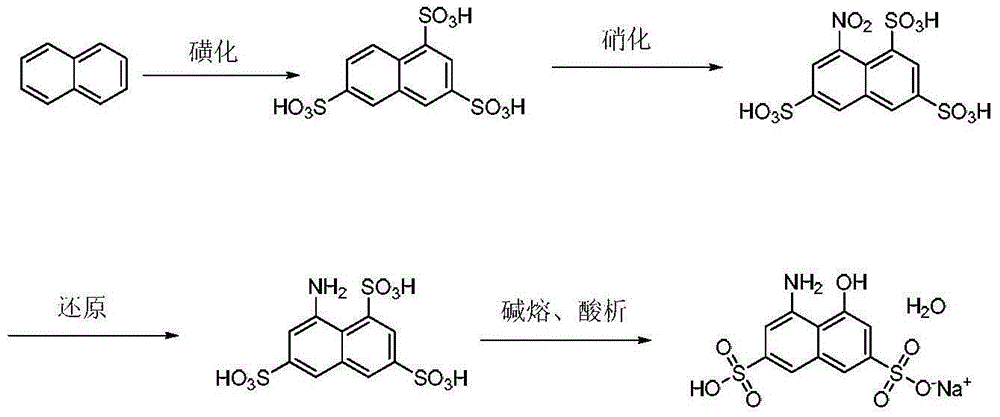

A kind of preparation method of H acid monosodium salt

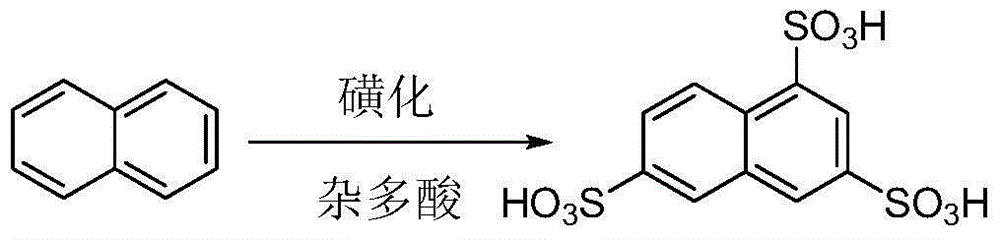

A monosodium salt and sodium salt technology, applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of high acidity of sulfonation reaction, harsh reaction conditions, high reaction temperature, etc., and achieve the reduction of sulfonation temperature and sulfonation reaction conditions Mild, highly catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In the flask, drop into refined naphthalene 400g, molybdenum vanadium phosphoheteropolyacid H 4 PMo 11 VO 4015g, then raise the temperature to 80-100°C to melt all the refined naphthalene, then add 350g of sulfuric acid, after the addition, raise the temperature to 110-125°C and keep it warm for 1h, then lower the temperature to below 80°C, add 50g of sulfuric acid, and then cool down to 50 ~60°C, add 500g of sulfur trioxide, control the feeding temperature below 100°C, raise the temperature to 135-145°C for 5 hours after the addition, and keep the temperature for 5 hours. After the reaction, the sulfonated material is obtained, and the acid value is about 60%. - The total yield of trisulfonic acid is 94%, and the content of 1,3,6-naphthalenetrisulfonic acid is 83%.

[0053] After passing the test, control the feed rate of sulfonated material and nitric acid, and continuously enter the nitration reactor at a molar ratio of 1:1.2. Control the temperature of the reactor...

Embodiment 2

[0060] In the flask, drop into refined naphthalene 400g, molybdenum vanadium phosphoheteropolyacid H 4 PMo 11 VO 40 5g, then raise the temperature to 80-100°C to melt all the refined naphthalene, then add 350g of sulfuric acid, after the addition, raise the temperature to 110-125°C and keep it warm for 1h, then lower the temperature to below 80°C, add 50g of sulfuric acid, and then cool down to 50 ~60°C, add 500g of sulfur trioxide, control the feeding temperature below 100°C, raise the temperature to 135-145°C for 5 hours after the addition, and keep the temperature for 5 hours. After the reaction, the sulfonated material is obtained, and the acid value is about 60%. - The total yield of trisulfonic acid is 90%, and the content of 1,3,6-naphthalenetrisulfonic acid is 81%.

[0061] After passing the test, control the feed rate of sulfonated material and nitric acid, and continuously enter the nitration reactor at a molar ratio of 1:1.2. Control the temperature of the reactor...

Embodiment 3

[0066] In the flask, drop into refined naphthalene 400g, molybdenum vanadium phosphoheteropolyacid H 5 PMo 10 VO 40 15g, then raise the temperature to 80-100°C to melt all the refined naphthalene, then add 350g of sulfuric acid, after the addition, raise the temperature to 110-125°C and keep it warm for 1h, then lower the temperature to below 80°C, add 50g of sulfuric acid, and then cool down to 50 ~60°C, add 500g of sulfur trioxide, control the feeding temperature below 100°C, raise the temperature to 135-145°C for 5 hours after the addition, and keep the temperature for 5 hours. After the reaction, the sulfonated material is obtained, and the acid value is about 60%. - The total yield of trisulfonic acid was 92%, and the content of 1,3,6-naphthalenetrisulfonic acid was 81%.

[0067] After passing the test, control the feed rate of sulfonated material and nitric acid, and continuously enter the nitration reactor at a molar ratio of 1:1.2. Control the temperature of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com