Humic acid chelated boron, magnesium, zinc and iron fertilizer and preparation method thereof

A technology of humic acid and chelated boron, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low utilization rate of medium and trace elements, pollution of surface and groundwater, soil compaction, etc., and achieve synergistic effect and sustained effect effect, excellent slow-release effect, and the effect of avoiding soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1.1. Add 12 kg of citric acid, 2 kg of ammonium borate, 6.5 kg of magnesium sulfate, 7.5 kg of zinc sulfate and 5 kg of ferrous sulfate into the reaction kettle, add 50 kg of water, react at 80°C for 60 minutes, and then add 15 kg of rotten phytic acid, reacted at 80°C for 90 minutes, and then dried through pressure filtration to obtain medium and trace element chelated fertilizers;

[0029] 1.2. Mix 1 kg of abamectin and 0.4 kg of diazinon and dissolve it with 30 kg of water to prepare a mixed solution of abamectin and diazinon. Mix 30 kg of urea, 10 kg of diammonium hydrogen phosphate, and 15 kg of sulfuric acid Potassium and 30 kilograms of boron-magnesium slag are added in the medium and trace element chelated fertilizer prepared in step 1.1, mixed evenly, pulverized to 80 mesh, added in the granulator, and sprayed with abamectin and diazinon mixed solution granules to prepare humic acid chelated boron magnesium zinc iron fertilizer.

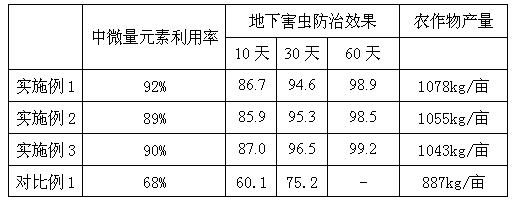

[0030] Table 1

[0031]

Embodiment 2

[0033] 1.1. Add 15 kg of citric acid, 1 kg of ammonium borate, 8 kg of magnesium sulfate, 7 kg of zinc sulfate and 6.5 kg of ferrous sulfate into the reaction kettle, add 50 kg of water, react at 90°C for 40 minutes, and then add 10 kg of rotten phytic acid, reacted at 90°C for 60 minutes, and then dried through pressure filtration to obtain medium and trace element chelated fertilizers;

[0034] 1.2. Mix 2 kg of abamectin and 0.3 kg of diazinon and dissolve it with 50 kg of water to prepare a mixed solution of abamectin and diazinon. Mix 20 kg of urea, 15 kg of diammonium hydrogen phosphate, and 10 kg of sulfuric acid Potassium and 40 kilograms of boron-magnesium slag are added in the medium and trace element chelated fertilizer prepared in step 1.1, mixed uniformly, pulverized to 100 mesh, added in the granulator, and sprayed with the mixed solution of abamectin and diazinon granules to prepare humic acid chelated boron magnesium zinc iron fertilizer.

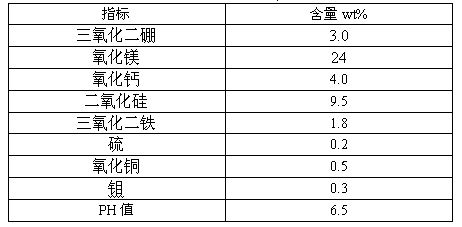

[0035] Table 2

[0...

Embodiment 3

[0038] 1.1. Add 14kg of citric acid, 1.5kg of ammonium borate, 7kg of magnesium sulfate, 7.2kg of zinc sulfate and 6kg of ferrous sulfate into the reaction kettle, add 50kg of water, react at 85°C for 50min, and then add 12kg of rotten phytic acid, reacted at 85°C for 75 minutes, and then dried through pressure filtration to obtain medium and trace element chelated fertilizers;

[0039] 1.2, 1.5 kg of abamectin and 0.35 kg of diazinon are mixed and dissolved in 40 kg of water to prepare a mixed solution of abamectin and diazinon, 25 kg of urea, 12 kg of diammonium phosphate, 12 kg of sulfuric acid Potassium and 35 kilograms of boron-magnesium slag are added in the medium and trace element chelated fertilizer prepared in step 1.1, mixed uniformly, pulverized to 80 mesh, added in the granulator, and sprayed with abamectin and diazinon mixed solution granules to prepare humic acid chelated boron magnesium zinc iron fertilizer.

[0040] table 3

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com