A traction device for an off-road tractor

A tractor and garbage tractor technology, applied in the field of off-road garbage tractors, can solve the problems of unreasonable space layout, stability to be improved, and easy wear and tear of king pins, so as to achieve compact structure, high bearing pressure, stable and safe rotation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

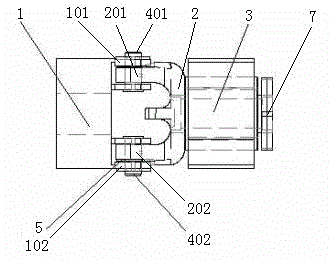

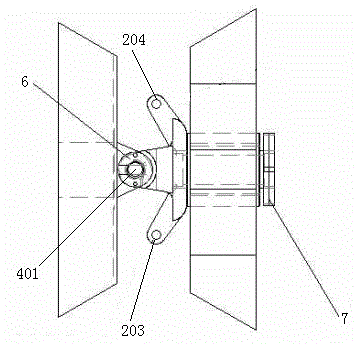

[0017] Referring to the accompanying drawings, this embodiment includes a traction box 1, a traction shaft 2, a traction shaft fixing box 3, a first traction kingpin 401, a second traction kingpin 402, a wear-resistant flat pad 5, a lock plate 6 and a traction shaft fixing nut 7. The traction box 1 is welded on the left and right longitudinal beams of the front frame. A pair of connectors I101 are provided on the upper rear end of the traction box 1, and a pair of connectors II102 are provided on the lower part. The connectors I101, connectors II102 is respectively provided with a kingpin mounting hole, and the middle of the traction box 1 is provided with a square hole for installing the rear drive shaft; the traction shaft fixing box 3 is welded on the left and right longitudinal beams of the rear frame, and the traction shaft 2 is equipped with a sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com