Preparation and application of metal ion doped CdSe quantum dot photocatalyst

A technology of metal ions and photocatalysts, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing the stability of quantum dots, photocatalytic performance suppression, etc., and achieve green environmental protection treatment technology , easy operation and efficient treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of NaHSe precursor solution:

[0026] Weigh 0.00075 mol of Se powder and 0.005 mol of NaHB into a glass reaction bottle, add deionized water, and magnetically stir to assist the reaction. 2 Protect until the white precipitate appears in the reaction, draw the supernatant liquid with a syringe, which is the NaHSe precursor.

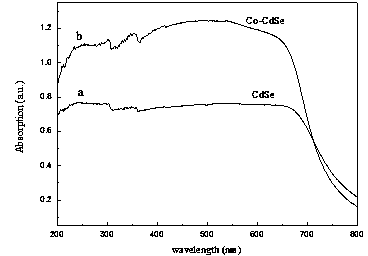

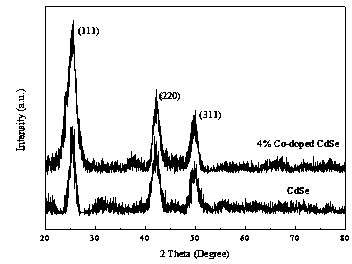

[0027] (2) Preparation of metal ion doped CdSe quantum dot photocatalyst:

[0028] Weigh 0.09134g cadmium chloride (CdCl 2 2.5H 2 O), 0.004g cobalt chloride (CoCl 2 ·6H 2 0) Put into a small beaker, add deionized water and stir until completely dissolved, then add 0.069g of 3-mercaptopropionic acid and mix well, then adjust the pH=9 of the solution with 1mol / L sodium hydroxide solution, then prepare the NaHSe precursor solution Inject into the above solution with a syringe and stir. After 15 minutes of purging nitrogen to remove oxygen, the solution will appear flocculent precipitation, pour it into a 50mL autoclave and heat it ...

Embodiment 2

[0031] (1) Preparation of NaHSe precursor solution:

[0032] Weigh 0.00075 mol of Se powder and 0.01 mol of NaHB into a glass reaction bottle, add deionized water, and magnetic stirring assists the reaction. 2 Protect until the white precipitate appears in the reaction, draw the supernatant liquid with a syringe, which is the NaHSe precursor.

[0033] (2) Preparation of metal ion doped CdSe quantum dot photocatalyst:

[0034] Weigh 0.09134g cadmium chloride (CdCl 2 2.5H 2 O), 0.004g cobalt chloride (CoCl 2 ·6H 2 0) Put into a small beaker, add deionized water and stir until completely dissolved, then add 0.069g of 3-mercaptopropionic acid after fully mixing, adjust the pH=9 of the solution with 1mol / L sodium hydroxide solution, then prepare the NaHSe precursor solution Inject into the above solution with a syringe and stir. After 15 minutes of purging nitrogen to remove oxygen, the solution will appear flocculent precipitation, pour it into a 50mL autoclave and heat it in...

Embodiment 3

[0037] (1) Preparation of NaHSe precursor solution:

[0038]Weigh 0.00075 mol of Se powder and 0.0015 mol of NaHB into a glass reaction bottle, add deionized water, and magnetic stirring assists the reaction. 2 Protect until the white precipitate appears in the reaction, draw the supernatant liquid with a syringe, which is the NaHSe precursor.

[0039] (2) Preparation of metal ion doped CdSe quantum dot photocatalyst:

[0040] Weigh 0.09134g cadmium chloride (CdCl 2 2.5H 2 O), 0.004g cobalt chloride (CoCl 2 ·6H 2 0) Put into a small beaker, add deionized water and stir until completely dissolved, then add 0.069g of 3-mercaptopropionic acid and mix well, then adjust the pH=9 of the solution with 1mol / L sodium hydroxide solution, then prepare the NaHSe precursor solution Inject into the above solution with a syringe and stir. After 15 minutes of purging nitrogen to remove oxygen, the solution will appear flocculent precipitation, pour it into a 50mL autoclave and heat it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com