Foam metal filtering type oil separator

A foam metal and oil separator technology, which is applied in separation methods, dispersed particle separation, and dispersed particle filtration, etc., can solve the problems of ineffective return of oil, large airflow pressure drop, and ineffective separation of oil droplets. Enhanced chance of collision, reduced pressure drop, effects of excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

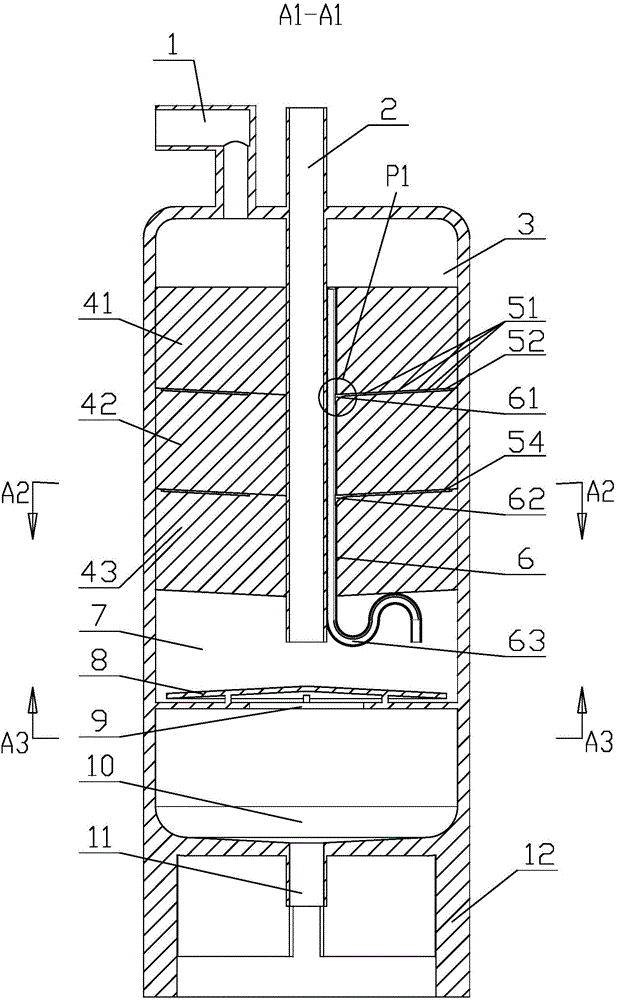

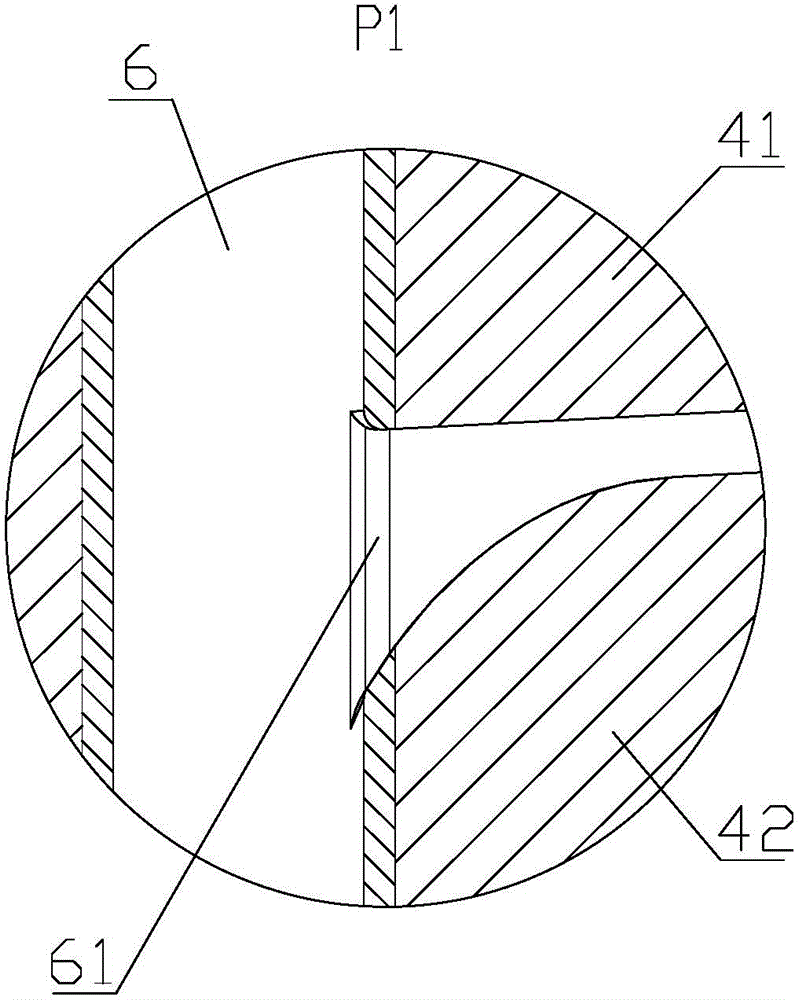

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0032] Such as figure 1 and figure 2 As shown, this embodiment discloses a metal foam filter type oil separator, the metal foam filter type oil separator has a vertical cylindrical outer cylinder 3, the bottom of the outer cylinder 3 is provided with a bracket 12 for supporting the outer cylinder 3 , the top of the outer cylinder 3 is provided with an air inlet port 1 and an air outlet duct 2 . One end of the air inlet port 1 communicates with the top of the outer cylinder 3, and the other end is used for feeding gas mixed with oil droplets. The air outlet duct 2 is located at the center of the top of the outer cylinder 3 , its top end protrudes from the outer cylinder 3 , and its bottom end extends to the cavity 7 in the outer cylinder 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com