Simple mask for efficiently filtering PM2.5 and manufacturing method of simple mask

A high-efficiency filtration and mask technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of complex structure, cumbersome manufacturing process, and increased manufacturing cost, and achieve the effect of improving air permeability, simple manufacturing process, and no complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

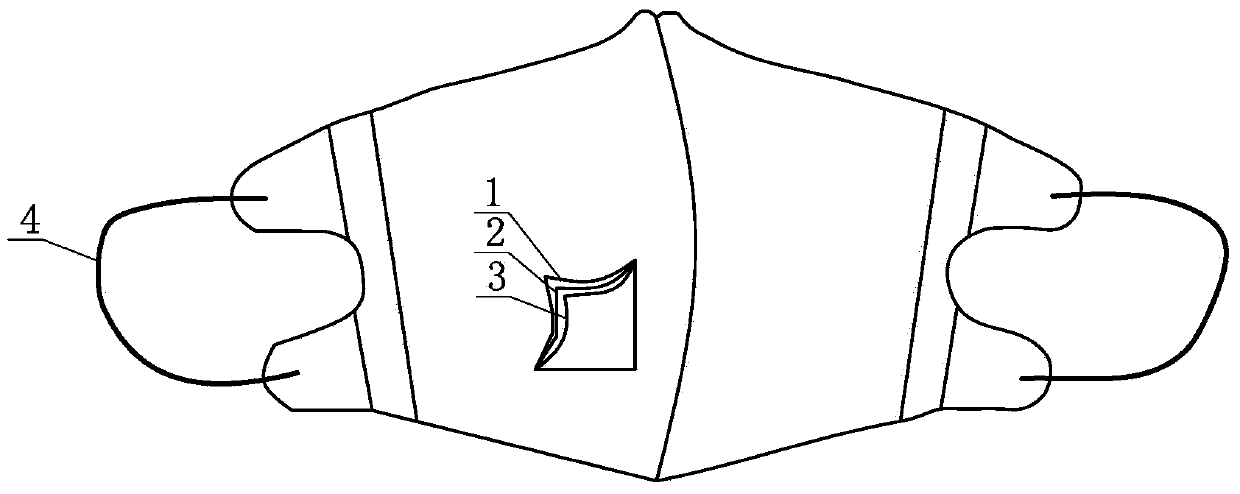

[0035] A high-efficiency filter for PM 2.5 Simple mask, as a filter with PM 2.5 Functional mask use. structured as figure 1 As shown, it includes a mask body used to cover the mouth and nose of the wearer, and a pair of ear hooks 4 protrude from both sides of the mask body, and a pair of ear hooks 4 are used for hooking to the wearer's ear.

[0036] The mask body is a three-layer structure forming a stacked shape, which is the outer layer of polypropylene spunbonded nonwoven fabric 1, the middle layer of ultrafine denier electret meltblown fiber nonwoven fabric 2, and the polypropylene spunbonded nonwoven fabric from outside to inside. Cloth inner layer 3, when the mask is worn, the inner layer 3 of polypropylene spunbonded nonwoven fabric faces the wearer, and the outer layer 1 of polypropylene spunbonded nonwoven fabric and the inner layer 3 of polypropylene spunbonded nonwoven fabric are evenly clothed with Breathable holes, the breathable holes run through the outer la...

Embodiment 2

[0044] A high-efficiency filter for PM 2.5 Simple and easy mouth mask, as shown in structure embodiment 1, difference is:

[0045] Polypropylene spunbonded non-woven outer layer 1 unit area weight is 22g / m 2 , ultra-fine denier electret melt-blown fiber nonwoven middle layer 2 unit area weight 25g / m 2 , the fineness of the fibers constituting the middle layer 2 of the ultra-fine denier electret meltblown nonwoven fabric is 0.01 denier, and the weight per unit area of the inner layer 3 of the polypropylene spunbonded nonwoven fabric is 18g / m 2 .

[0046] The thickness of the inner layer of the polypropylene spunbonded nonwoven fabric is 0.2mm, the thickness of the middle layer of the ultrafine denier electret meltblown fiber nonwoven fabric is 0.1mm, and the thickness of the outer layer of the polypropylene spunbonded nonwoven fabric is 0.2mm.

[0047] In this embodiment, the preparation steps of the middle layer of the ultrafine denier electret melt-blown fiber nonwoven ...

Embodiment 3

[0052] A high-efficiency filter for PM 2.5 Simple and easy mouth mask, as shown in structure embodiment 1, difference is;

[0053] The weight per unit area of the outer layer of the polypropylene spunbonded nonwoven fabric is 28g / m 2 , the weight per unit area of the middle layer of ultra-fine denier electret melt-blown fiber nonwoven fabric is 30g / m 2 , the weight per unit area of the inner layer of polypropylene spunbonded non-woven fabric is 25g / m 2 , The fineness of the fibers constituting the middle layer of the ultra-fine denier electret melt-blown fiber nonwoven fabric is 0.1 denier.

[0054] The thickness of the inner layer of the polypropylene spunbonded nonwoven fabric is 0.6mm, the thickness of the middle layer of the ultrafine denier electret meltblown fiber nonwoven fabric is 0.4mm, and the thickness of the outer layer of the polypropylene spunbonded nonwoven fabric is 0.55mm.

[0055] In this embodiment, the preparation steps of the middle layer of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com