A kind of preparation method of salt-baked chicken flavor nutritional seasoning powder

A technology of nutritional seasoning powder and salt-baked chicken, which is applied in the field of food additives, can solve the problems of low added value, lack of effective recycling, waste of resources, etc., and achieve the effect of rich nutrition, pure and thick natural bone flavor, and stable ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

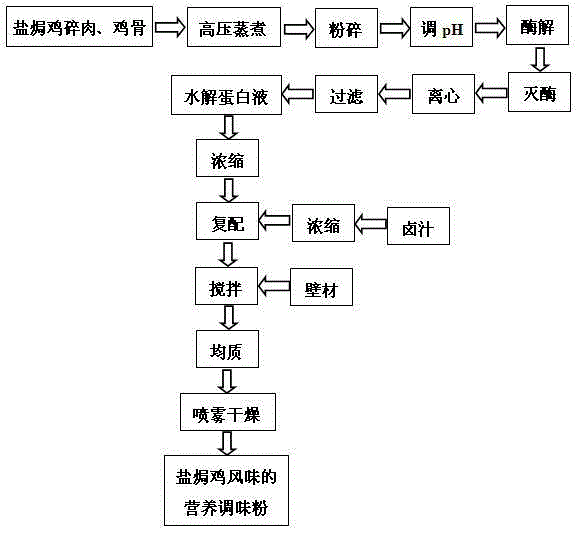

Method used

Image

Examples

Embodiment 1

[0041] S1. Raw material pretreatment: Put the marinated salt-baked chicken bones and minced meat in an autoclave at 110°C for 25 minutes, and then crush them with a high-speed grinder to make meat and bone paste. The particle size of the meat and bone paste is 9.5mm.

[0042] S2. Adjust pH: Weigh 100g of meat and bone paste into a container, add deionized water to make the mass percentage concentration of meat and bone paste to 12%, and adjust the pH to 5.5, (can be detected by Leici PHS-2F pH meter ).

[0043] S3. Enzymolysis reaction: Add 0.5% compound flavor protease to the above container according to the mass percentage of enzyme in the meat and bone paste, keep the temperature at 40° C., and enzymolysis time for 2 hours.

[0044] S4. Enzyme inactivation treatment: the reaction system after enzymolysis was placed in a boiling water bath at 100° C. for enzymatic inactivation treatment for 6 minutes.

[0045] S5. Separation of enzymatic hydrolyzate: place the enzymaticall...

Embodiment 2

[0055] S1. Raw material pretreatment: Put the marinated salt-baked chicken bones and minced meat in an autoclave at 120°C for 25 minutes, and then crush them with a high-speed grinder to make meat and bone paste. The particle size of the meat and bone paste is 7.0mm.

[0056] S2. Adjust pH: Weigh 100 g of meat and bone paste into a container, add deionized water to make the mass percentage of meat and bone paste 20%, and adjust the pH to 6.0.

[0057] S3. Enzymolysis reaction: Add 1.0% compound flavor protease to the above container according to the mass percentage of the enzyme in the meat and bone paste, keep the temperature at 45°C, and the enzymolysis time for 3 hours.

[0058] S4. Enzyme inactivation treatment: the reaction system after enzymolysis was placed in a boiling water bath at 100° C. for enzymatic inactivation treatment for 6 minutes.

[0059] S5. Separation of enzymatic hydrolyzate: put the enzymatically deactivated enzymolyzate in a centrifuge, centrifuge at ...

Embodiment 3

[0067] S1. Raw material pretreatment: Put the marinated salt-baked chicken bones and minced meat in an autoclave at 125°C for 30 minutes, and then crush them with a high-speed grinder to make meat and bone paste. The particle size of the meat and bone paste is 5.2mm.

[0068] S2. Adjust pH: Weigh 100 g of meat and bone paste into a container, add deionized water to make the mass percentage of meat and bone paste 25%, and adjust the pH to 6.5.

[0069] S3. Enzymolysis reaction: Add 1.5% compound flavor protease to the above container according to the mass percentage of the enzyme in the meat and bone slurry, keep the temperature at 50° C., and the enzymolysis time for 4 hours.

[0070] S4. Enzyme inactivation treatment: the reaction system after enzymolysis was placed in a boiling water bath at 100° C. for enzymatic inactivation treatment for 10 minutes.

[0071] S5. Separation of enzymolysis solution: put the enzymolysis solution after deactivation in a centrifuge, centrifuge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com