Rocket engine spraying pipe motion vision measuring method and portable infrared light emitting device used in same

A rocket engine and visual measurement technology, applied in portable lighting devices, devices using optical methods, measuring devices, etc., can solve problems such as the inability to correctly identify cooperation targets, and achieve simple structure, improved measurement accuracy, and simple measurement steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT One, a kind of rocket engine nozzle movement visual measurement method described in this specific embodiment comprises the following steps:

[0026] Step 1. Arranging a plurality of infrared luminescent points on the outer surface of the nozzle of the rocket engine,

[0027] Step 2, setting an infrared filter before the lens of the image acquisition device,

[0028] Step 3, connect the image acquisition signal output end of the image acquisition device with the image acquisition signal input end of the visual measurement system control computer,

[0029] Step 4. Aim the lens of the image acquisition device at the infrared light-emitting point,

[0030] Step 5, the image acquisition device performs image acquisition on a plurality of infrared light-emitting points on the outer surface of the nozzle of the rocket engine in motion, and sends the acquired images to the control computer of the visual measurement system,

[0...

specific Embodiment approach 2

[0032] Embodiment 2. The difference between this embodiment and the visual measurement method for rocket engine nozzle motion described in Embodiment 1 is that the infrared light-emitting point is realized by a portable infrared light-emitting device.

specific Embodiment approach 3

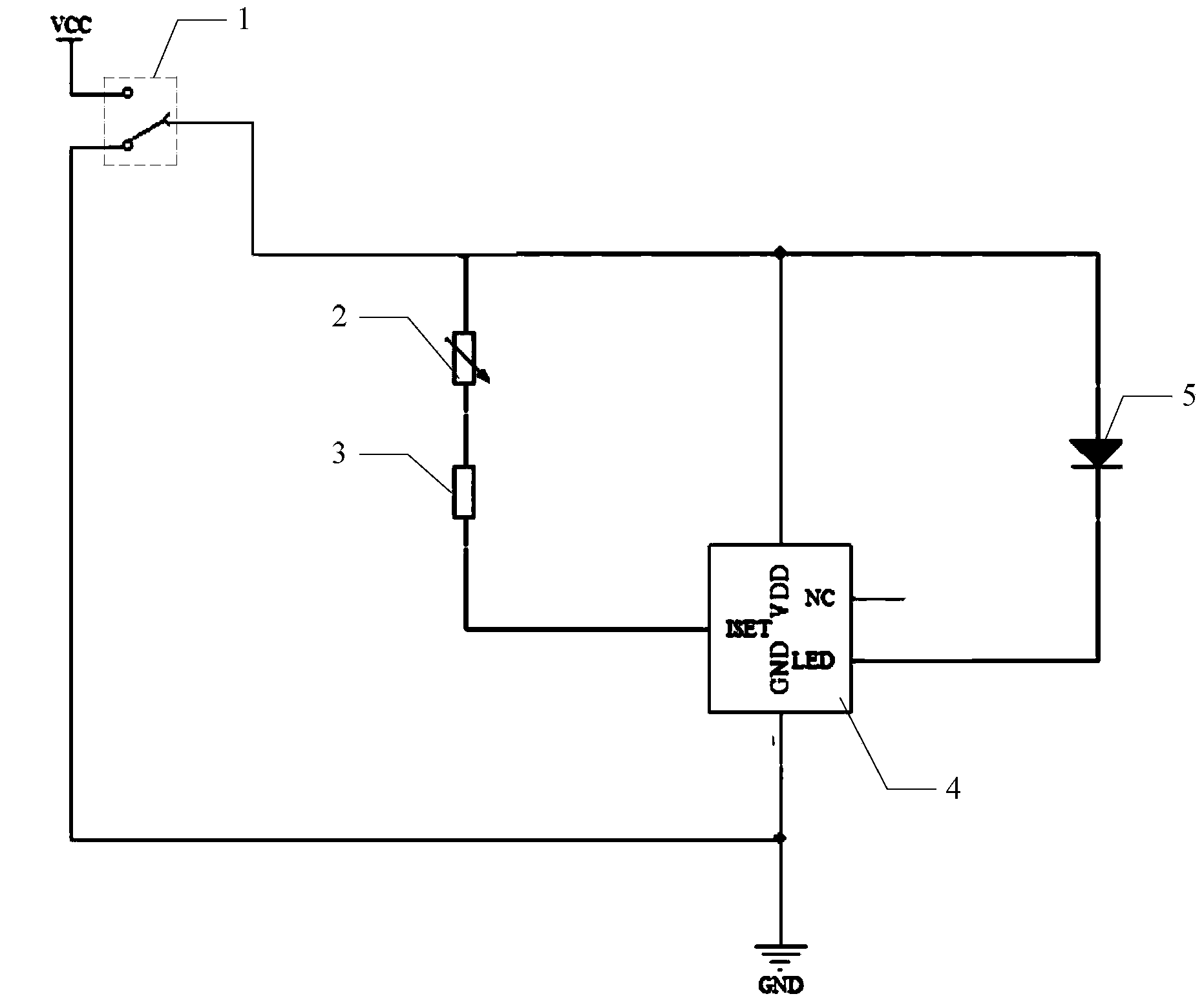

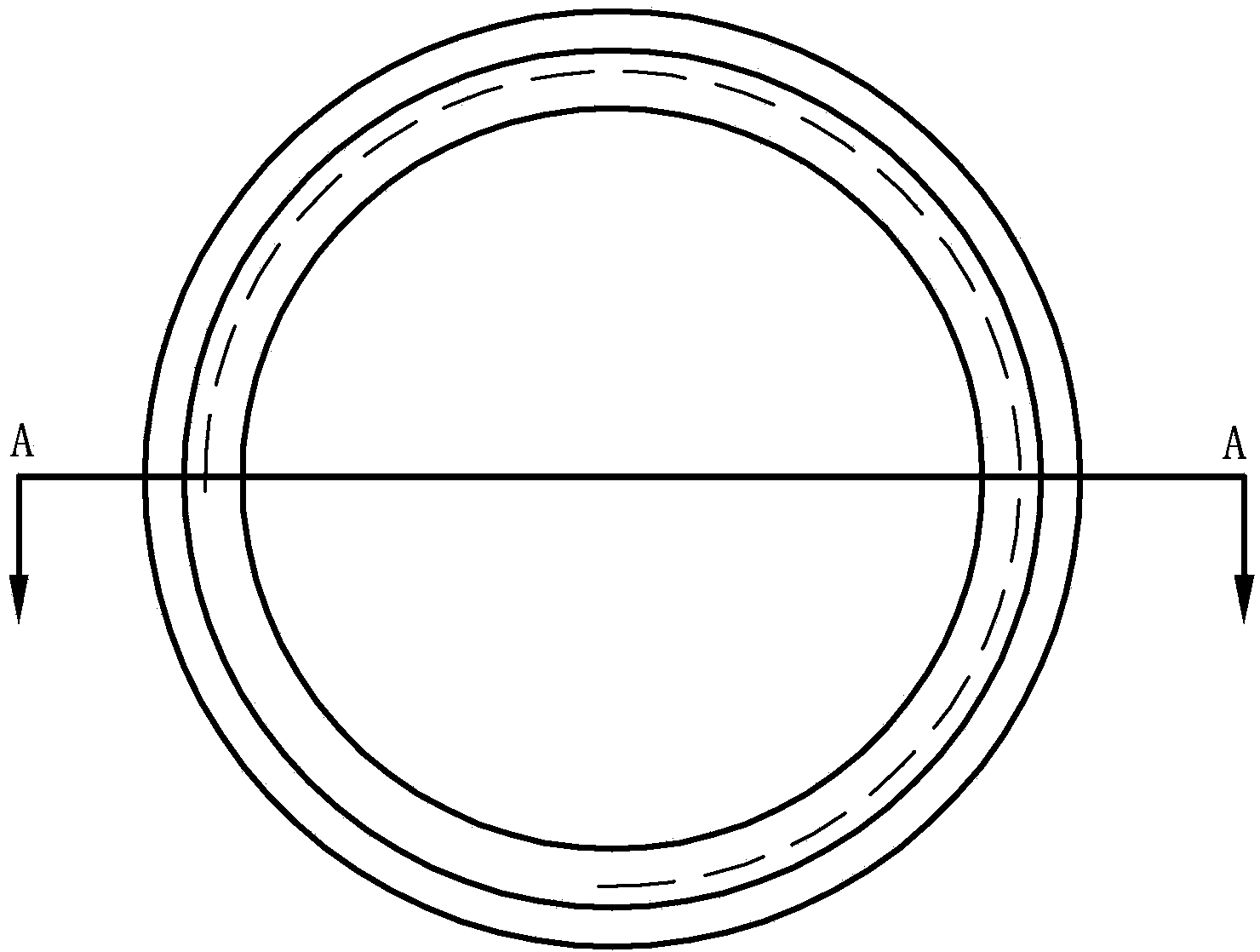

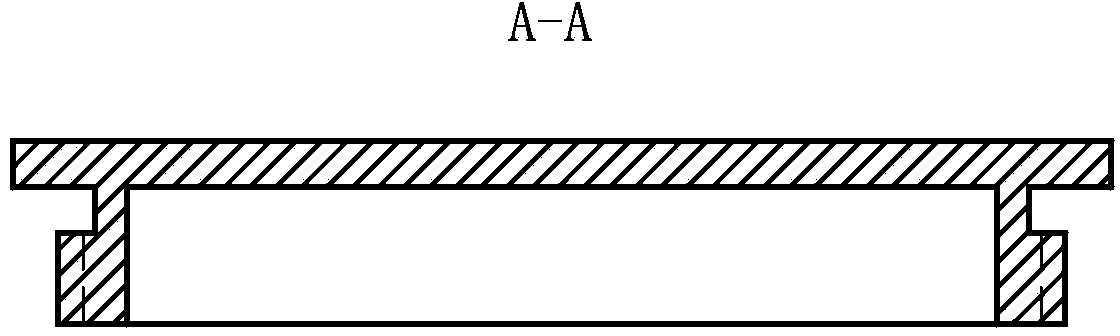

[0033] Specific embodiment three, combine Figure 1-Figure 10 Illustrate this specific embodiment, the portable infrared light-emitting device used in a kind of rocket engine nozzle motion visual measurement method described in specific embodiment 2 comprises infrared LED5, LED drive circuit and shell, and described LED drive circuit is used for driving infrared LED5 emits light, and the LED driving circuit is integrated on the circuit board and installed in the housing,

[0034] The LED drive circuit includes power supply VCC, fixed value resistor 3, adjustable resistor 2, constant current chip 4, toggle switch 1 and MiniUSB charging interface, one end of the adjustable resistor 2 is connected to the positive pole of the infrared LED5, and the other end of the adjustable resistor 2 One end is connected to one end of the fixed value resistor 3, the other end of the fixed value resistor 3 is connected to the constant current setting end of the infrared LED 5 of the constant cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com