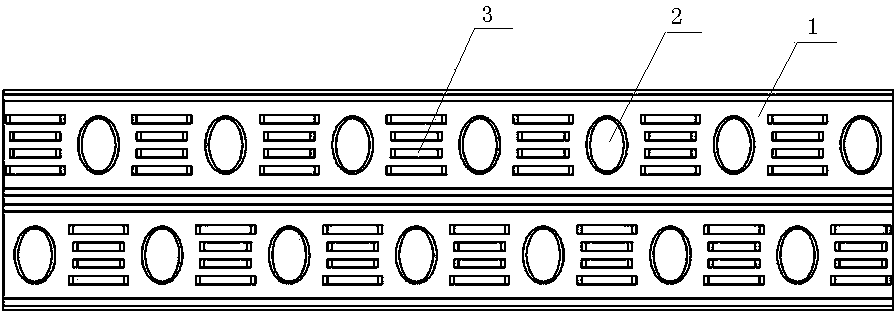

Fin structure of heat exchanger

A heat exchanger and fin technology, applied in the field of heat exchanger fin structure, can solve the problems of large heat exchanger tube resistance and poor heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] See figure 1 , a heat exchanger fin structure, which includes a heat exchanger fin body 1, the heat exchanger fin body 1 is provided with an elliptical through hole 2, and the heat exchanger fin body 1 is provided with horizontal and vertical holes respectively A plurality of through holes, and a plurality of bridge grooves 3 are arranged between the 2 transverse oval through holes.

[0009] Elliptical tubes have less drag loss. Compared with the conventional circular tube heat exchanger, the main difference between the elliptical tube heat exchanger is that the circular tube is replaced by an elliptical tube. Due to the good aerodynamic characteristics of the elliptical tube, the flow direction of the fluid is similar to the streamline, the air can flow smoothly from the surface, and the separation point of the airflow and the tube is moved back, which reduces the vortex area behind the tube, thereby reducing the air resistance, which is the same as Compared with rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com