Condenser and Condenser Repair and Leak Checking Method

A condenser, square technology, applied in steam engine installations, machines/engines, etc., can solve problems such as high cost, pollution of the environment, waste of water resources, etc. Significantly, the effect of reducing pipe resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

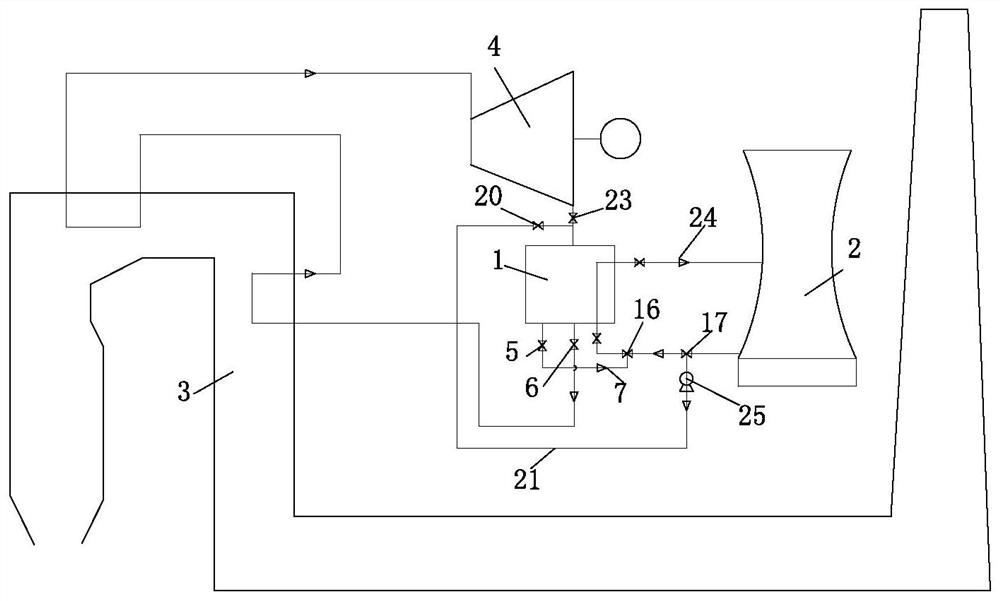

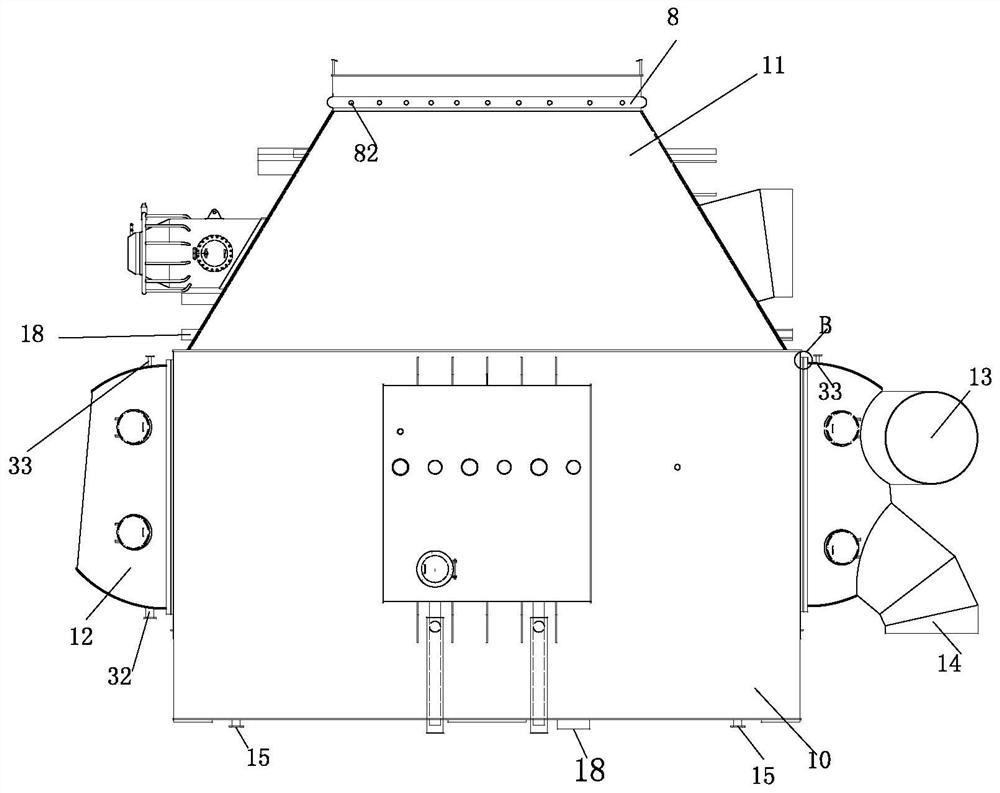

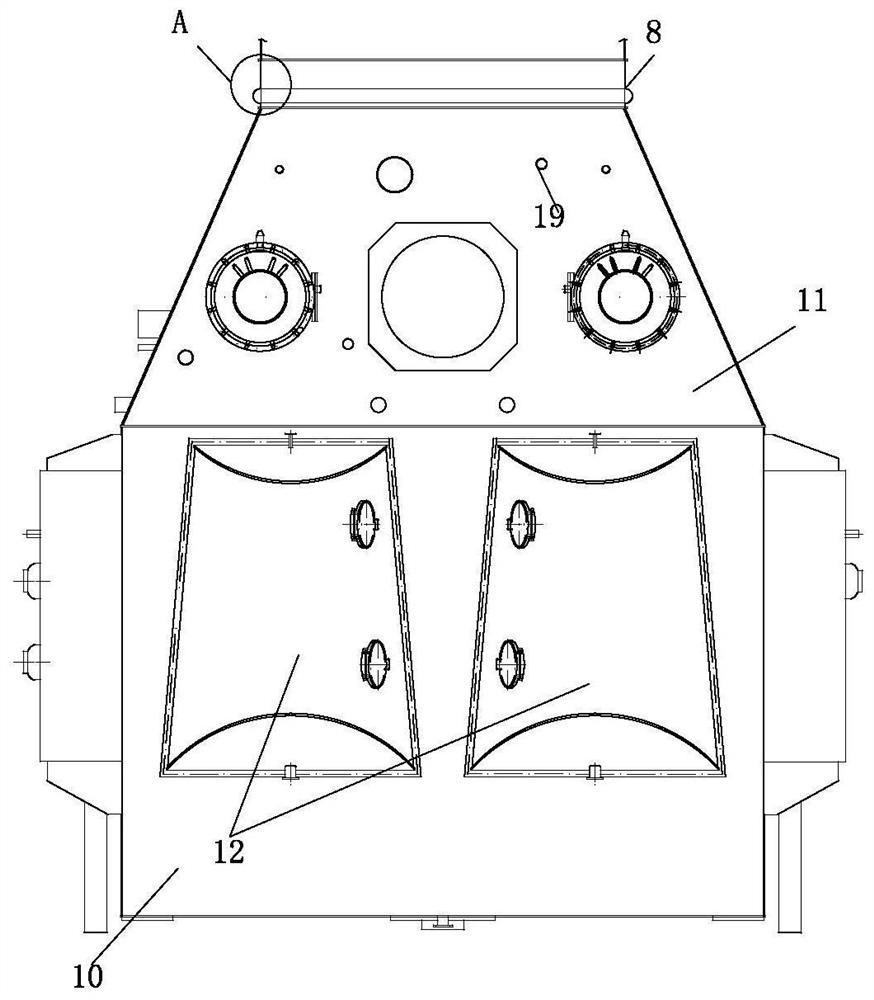

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] The directions such as front, rear, left, right, up and down involved in the following embodiments are all in the form of figure 1 The definition of the state of the condenser shown in , the specific orientation will be different due to the different positions of the condenser.

[0022] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the condenser 1 in the present invention includes a housing 10 whose bottom is fixedly connected to the ground through a support, and there is a space of 0.5-1 meter between the lower surface of the housing 10 and the ground, which is convenient for the housing 10 Bottom equipment connection and installation. A heat exchange chamber is formed inside the casing 10, such as Figure 6 As shown, a connecting neck 11 forming the steam inlet chamber 9 and connected to the steam outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com