Refrigeration device and maintenance method thereof

A refrigeration device and container technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of threatening the health of operators, scalding operators, and long time consumption, so as to achieve short time consumption and cost saving , fast perfusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

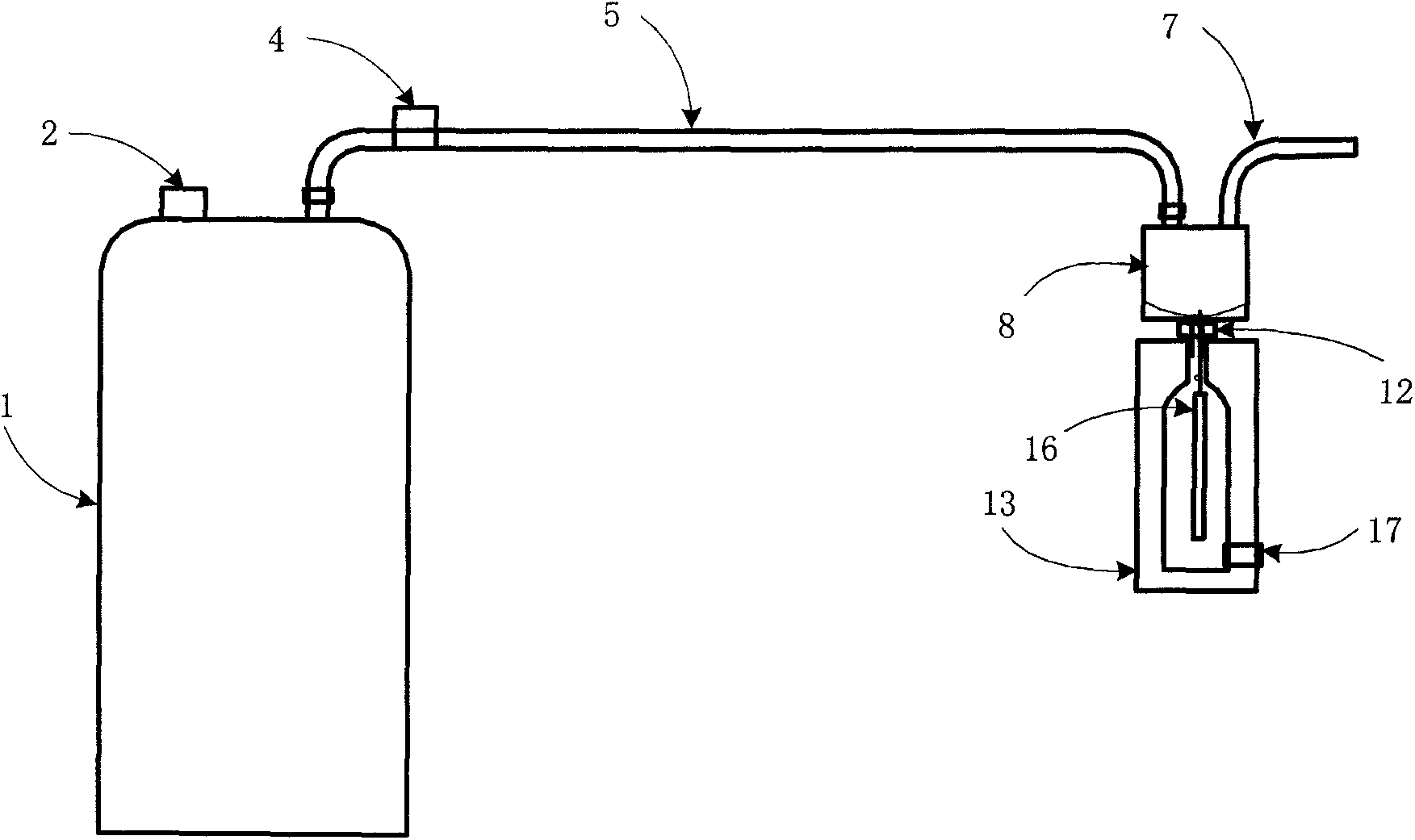

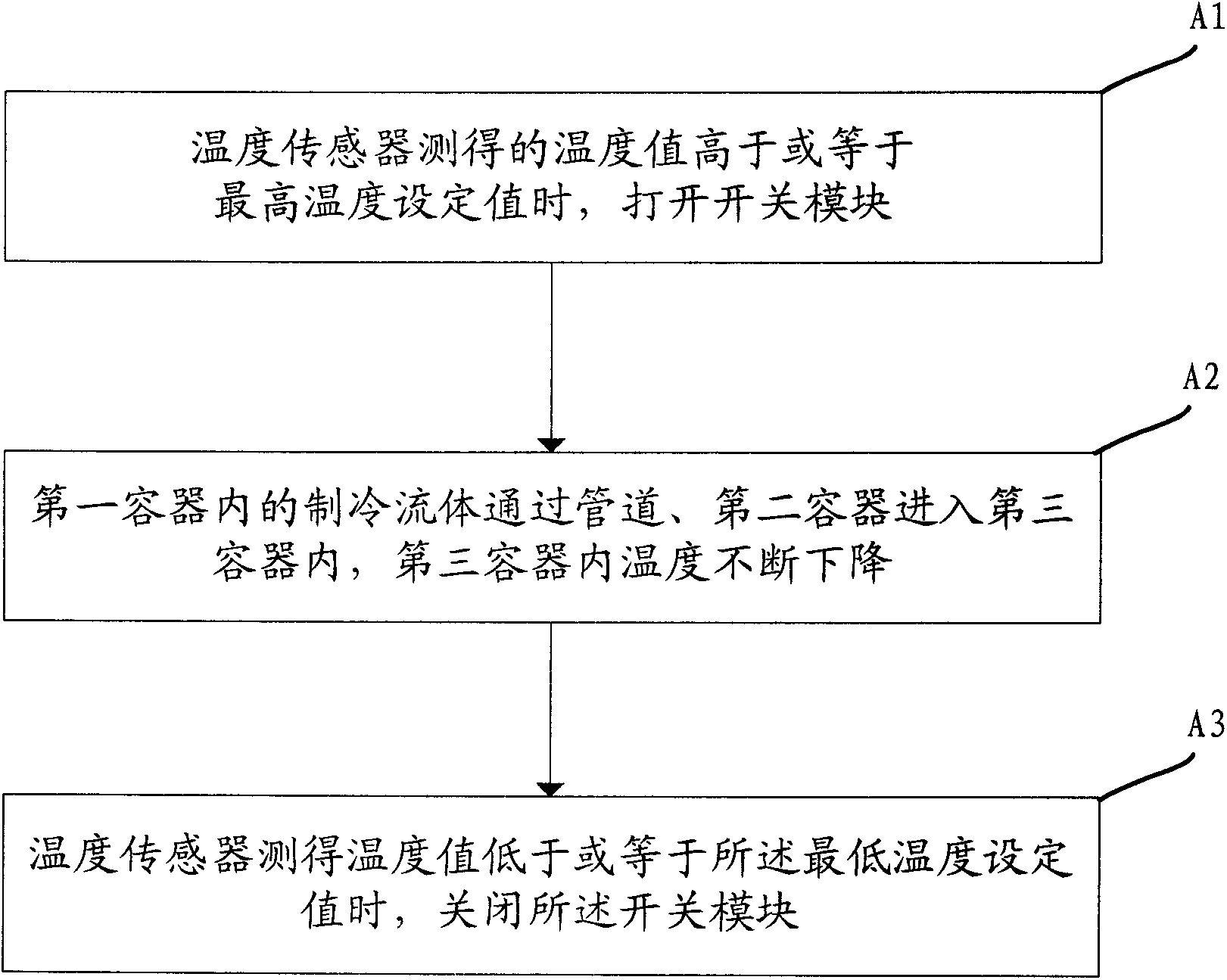

[0042] figure 1 The structure diagram of the refrigeration device of the detector of the embodiment of the present invention is schematically given, such as figure 1 As shown, the cooling device of the detector includes:

[0043] The first container 1 is provided with a pressurization module 2 on the first container 1 and contains refrigeration fluids, such as liquid nitrogen, liquid helium and other liquefied gases;

[0044] The pipe 5 is used to connect the outlet end of the first container with the inlet end of the second container; the pipe 5 should meet the requirements of thermal insulation, such as stainless steel pipes and wrapped around the outer edge of the pipe Insulation Materials;

[0045] The switch module 4 is arranged on the pipeline; the switch module adopts valves such as solenoid valves;

[0046] The second container 8, the outlet end of the second container 8 is connected to the inlet end of the third container 13 through the connecting member 12; the second contai...

Embodiment 2

[0067] An application example of the refrigeration device and its maintenance method according to Embodiment 1 of the present invention in a Fourier spectrometer.

[0068] In this application example, the first container adopts a liquid nitrogen tank with a booster module and an outlet on the top. The outlet is connected to a solenoid valve. One end of a stainless steel pipe wrapped with insulation cotton on the outer edge is connected to the solenoid valve, and the other end is connected to the second The inlet end of the container. The second container adopts a stainless steel tank with a concave design at the bottom, and the lowest end of the second container is connected with the Dewar as the third container through a connecting part. One end lead of the temperature sensor passes through the fixing ring and is fixed on the top of the second container, the fixing ring is fixed on the fixing column, and the fixing column is arranged in the Dewar flask and fixed on the connectin...

Embodiment 3

[0077] An application example of the cooling device of the detector and its maintenance method in the Fourier spectrometer according to the first embodiment of the present invention.

[0078] In this application example, the first container uses a liquid nitrogen tank, with a booster module and an outlet on the top, and the outlet is connected to a solenoid valve. The pipeline adopts a double-layer structure. The inner layer is used to connect the solenoid valve and the inlet of the second container. The layer is evacuated. The second container adopts a stainless steel tank with a concave design at the bottom, and the lowest end of the second container is connected with the Dewar as the third container through a connecting part. One end lead of the temperature sensor passes through the fixing ring and is fixed on the connecting part, the fixing ring is fixed on the fixing column, and the fixing column is arranged in the Dewar and fixed on the connecting part. Through this fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com