Base section sinking well with waterproof structure

A waterproof structure and bottom section technology, applied in underwater structures, infrastructure engineering, caisson and other directions, can solve the problems of difficult pouring and compaction, the effect of waterproof measures is not particularly ideal, etc. Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

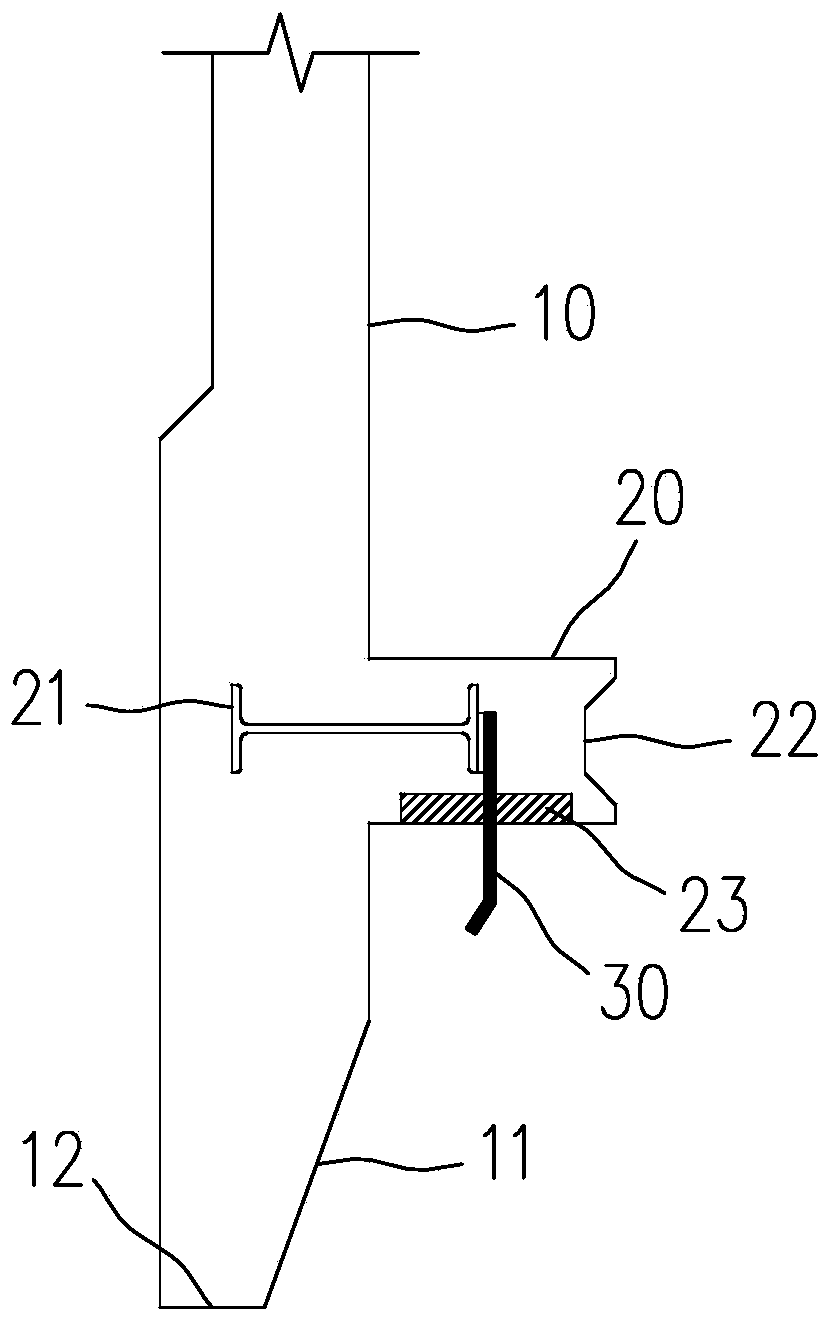

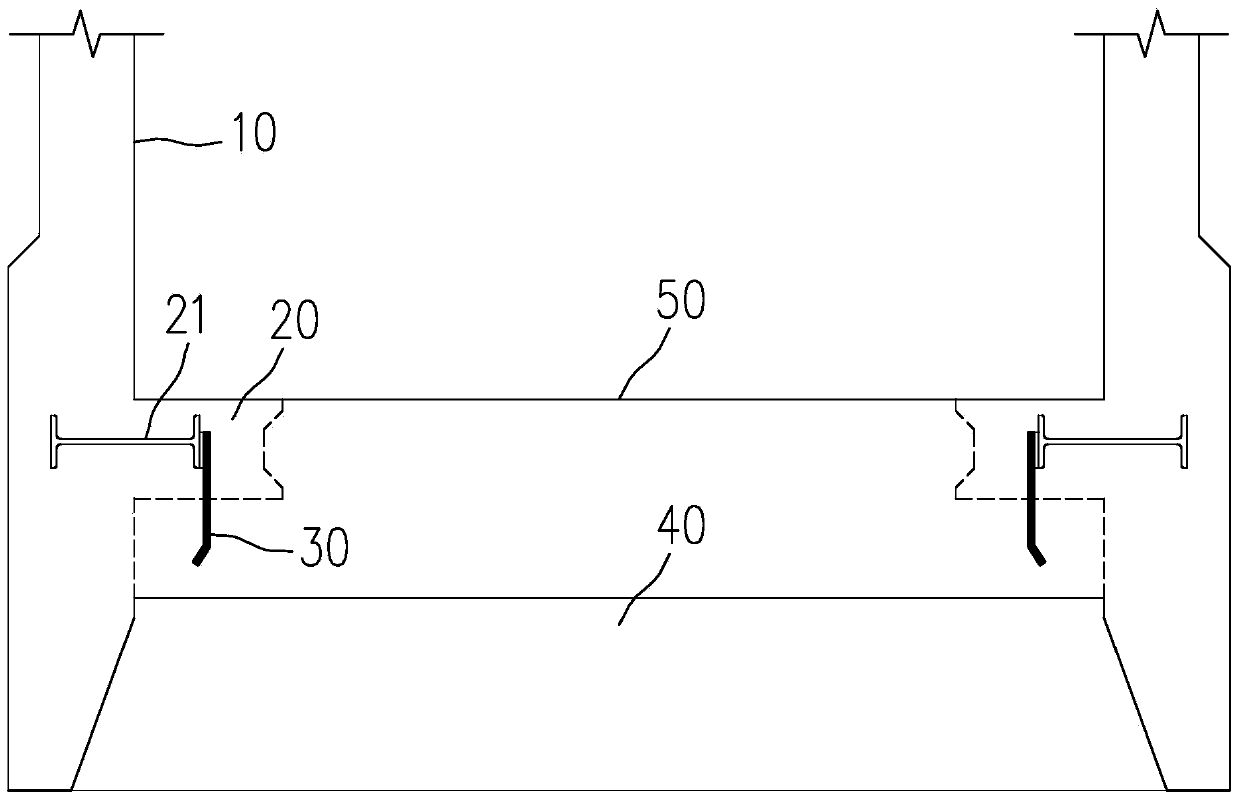

[0029] Such as figure 1 , 2 As shown, the inner well wall of the bottom caisson 10 is provided with several corbels 20 at the position where the bottom plate 50 is poured, and the corbels 20 are all along the radial plane of the bottom caisson 10 The inner side stretches flat; the corbel 20 is pre-embedded with a waterstop 30, one end of the waterstop 30 extends into the corbel 20 and is fixedly connected with the built-in steel plate 21 in the corbel 20, the waterstop The other end of 30 protrudes downward at the outside of corbel 20 , and one end of waterstop 30 protruding out of corbel 20 is bent toward the well wall side of bottom caisson 10 .

[0030] The end of one side of the corbel 20 extending horizontally to the inside of the bottom joint caisson 10 is provided with a post-casting groove 22 that is convenient for pouring the bottom plate 50, and the upper and lower ends of the post-casting groove 22 sink toward the bottom joint. The inner side of the well 10 is pro...

Embodiment 2

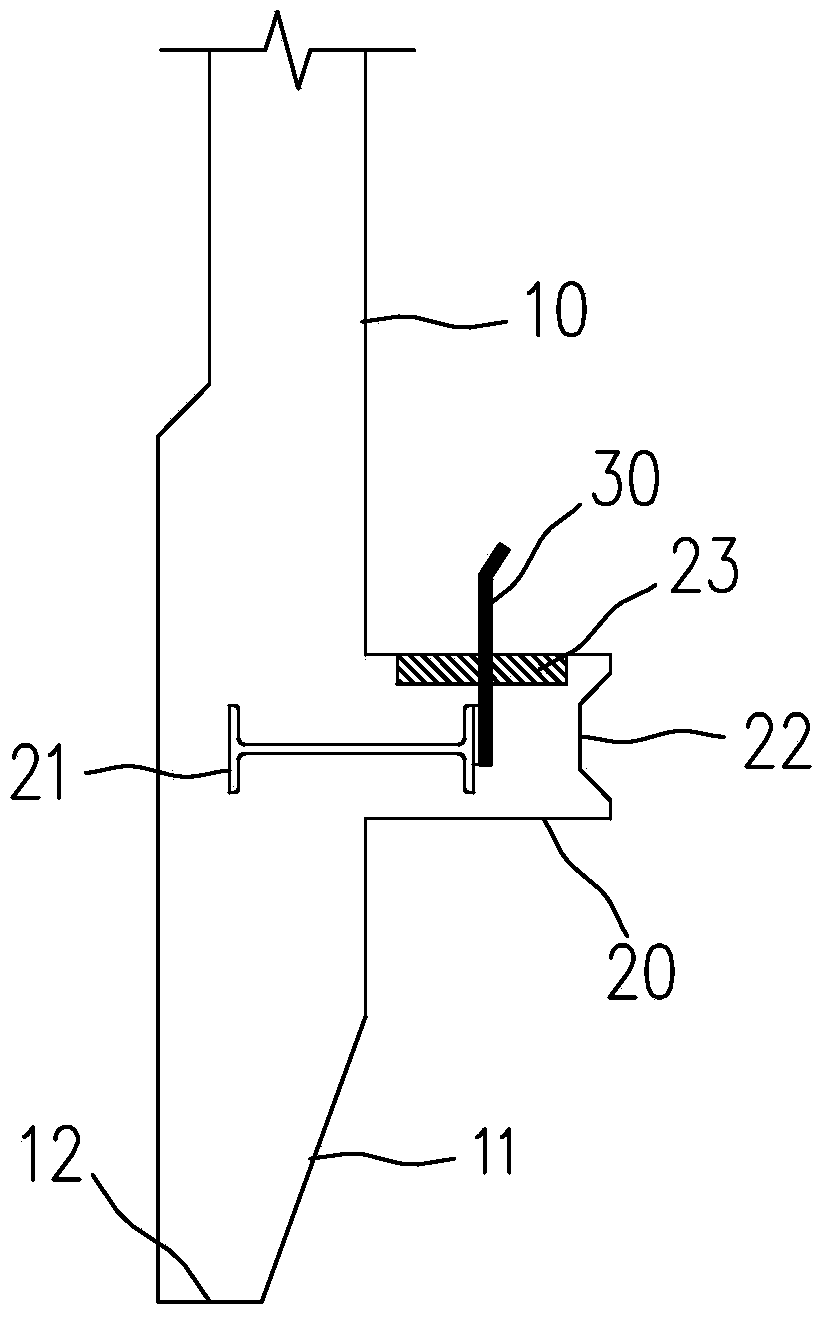

[0036] Such as figure 1 , 2 As shown, the inner well wall of the bottom caisson 10 is provided with several corbels 20 at the position where the bottom plate 50 is poured, and the corbels 20 are all along the radial plane of the bottom caisson 10 The inner side stretches flat; the corbel 20 is pre-embedded with a waterstop 30, one end of the waterstop 30 extends into the corbel 20 and is fixedly connected with the built-in steel plate 21 in the corbel 20, the waterstop The other end of the water stop 30 protrudes upwards outside the corbel 20 , and one end of the waterstop 30 protruding outside the corbel 20 is bent toward the inside of the bottom caisson 10 .

[0037] The end of one side of the corbel 20 extending horizontally to the inside of the bottom joint caisson 10 is provided with a post-casting groove 22 that is convenient for pouring the bottom plate 50, and the upper and lower ends of the post-casting groove 22 sink toward the bottom joint. The inner side of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com