Method and system for vertically prestressed steel strands in secondary tension low-retraction anchorage system

A vertical prestressing, steel strand technology, applied in the erection/assembly of bridges, bridge materials, bridges, etc., can solve the problems of large prestress loss, reduced service life of the main bridge box girder, low stress level, etc. The effect of large prestress loss, extended operation period and engineering quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following non-limiting examples illustrate the invention.

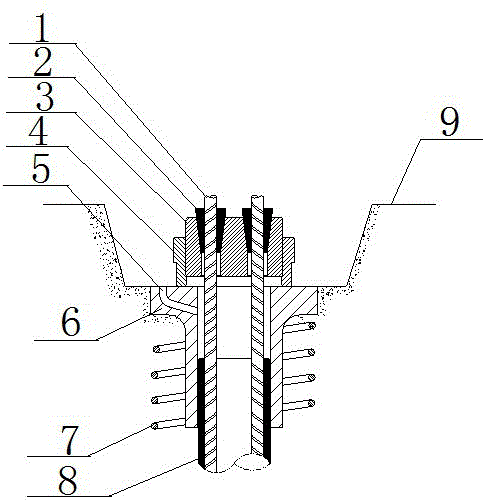

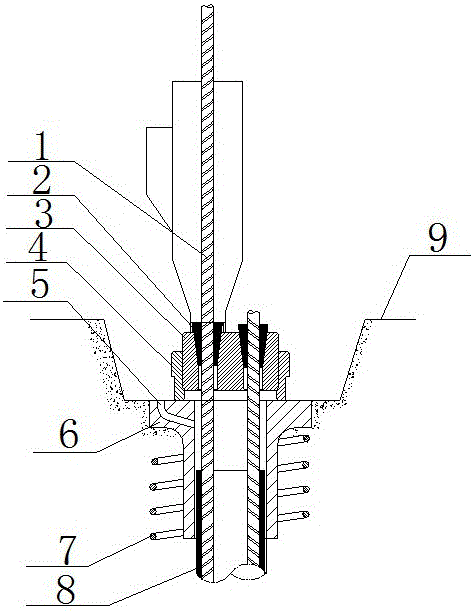

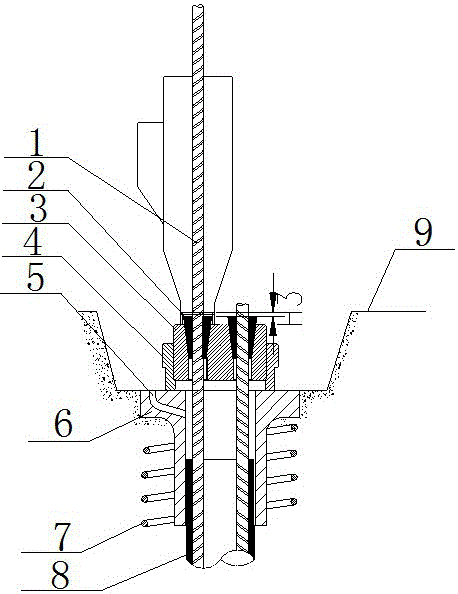

[0022] Such as Figures 1 to 3 As shown, a method for vertically prestressed steel strands in a secondary tension low-retraction anchorage system, in which the anchor cup 3 is externally threaded with a support nut 4, and the tension end pad 6 is placed below, and the support nut 4 supports the anchor cup 3. On the backing plate 6 at the tension end, the following steps are successively included:

[0023] One-time tensioning: single tension steel strand reinforcement 1 to the designed stress value σcom, holding load 120±30s, release tension, low retraction clip 2 anchor reinforcement reinforcement, three steel strand reinforcement reinforcement 1 in the same group The stretching is completed in sequence;

[0024] Secondary tensioning: After the primary tensioning low retraction clip 2 is anchored and retracted, at an interval of 2-16 hours, the anchor cup 3 of the steel strand reinforcement 1 of the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com