Preparation method of high-alkali vulcanized alkylphenate

A technology of sulfurized alkylphenate and alkylphenol, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems that do not involve the high-temperature detergency of sulfurized alkylphenate calcium, and achieve the effect of excellent high-temperature detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

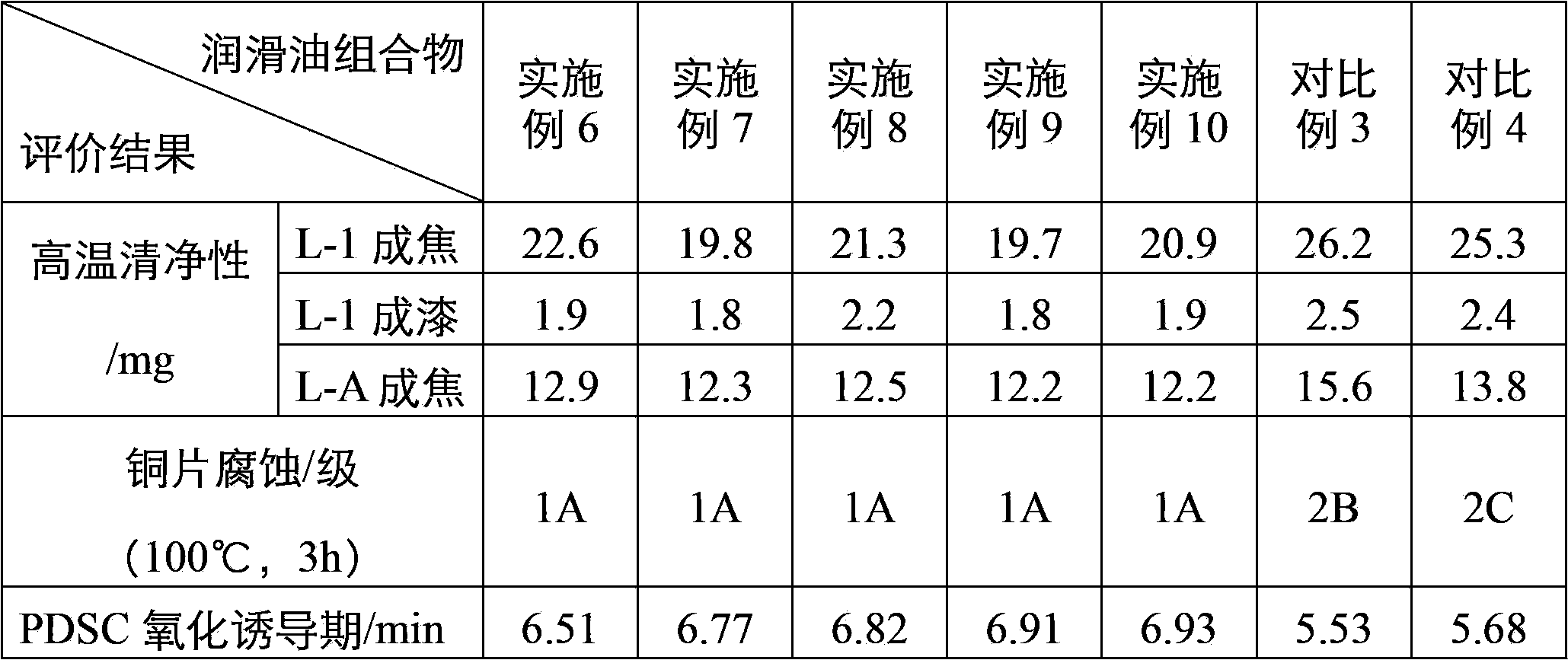

Examples

Embodiment 1

[0050] Embodiment 1 (methanol solution handles three times, adopts two kinds of demulsifiers each time)

[0051] In a 500ml three-necked flask equipped with a temperature control system and electric stirring, add 70 grams of dodecylphenol, 75 grams of 150SN neutral oil, stir for 15 minutes, then add 18 grams of sulfur, 9 grams of calcium oxide, and heat up to 90 ° C After reacting for 50 minutes, the color of the reaction material gradually becomes darker, and hydrogen sulfide gas is released, and the reaction tail gas is passed into a 10% sodium hydroxide solution absorption device. After the reaction, the material was cooled to 40°C, and 200 grams of 35% methanol solution was added to control the reaction temperature between 45-50°C, and the reaction was carried out for 30 minutes. At this time, there was a solution emulsification phenomenon, and the emulsified layer was 7% of the water layer. Add KR-12, T901 demulsifier mixture, the addition amount is 160ppm of the total ma...

Embodiment 2

[0052] Embodiment 2 (methanol solution handles three times, adopts three kinds of demulsifiers each time)

[0053] In a 500ml three-necked flask equipped with a temperature control system and electric stirring, add 70 grams of dodecylphenol, 75 grams of 150SN neutral oil, stir for 15 minutes, then add 18 grams of sulfur, 9 grams of calcium oxide, and heat up to 90 ° C After reacting for 50 minutes, the color of the reaction material gradually becomes darker, and hydrogen sulfide gas is released, and the reaction tail gas is passed into a 10% sodium hydroxide solution absorption device. After the reaction, the material was cooled to 40°C, and 200 grams of 35% methanol solution was added, and the reaction temperature was controlled between 45-50°C, and the reaction was carried out for 30 minutes. At this time, there was a solution emulsification phenomenon, and the emulsified layer was 6% of the water layer. Add The mixture of KR-12, T901 and polyisobutylene 1, the addition amou...

Embodiment 3

[0055] Embodiment 3 (methanol solution handles three times, adopts three kinds of demulsifiers each time)

[0056] In a 500ml three-necked flask equipped with a temperature control system and electric stirring, add 80 grams of dodecylphenol, 75 grams of 150SN neutral oil, stir for 15 minutes, then add 19 grams of sulfur, 8.5 grams of calcium oxide, and heat up to 90 ° C After reacting for 50 minutes, the color of the reaction material gradually becomes darker, and hydrogen sulfide gas is released, and the reaction tail gas is passed into a 10% sodium hydroxide solution absorption device. After the reaction, cool the material to 40°C, then add 200 grams of 40% methanol solution, and react for 40 minutes. At this time, the solution has emulsification, and the emulsified layer is 7% of the water layer. Add KR-12, T901 and polyisobutylene 1 The mixture, the addition amount is 130ppm of the total mass of dodecylphenol, the mass ratio between KR-12 and T901, polyisobutylene 1 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com