High-performance modified polypropylene and processing method for two-way stretch geogrid special material

A technology of geogrid and biaxial stretching, which is applied in the field of processing special materials for biaxially stretched geogrid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

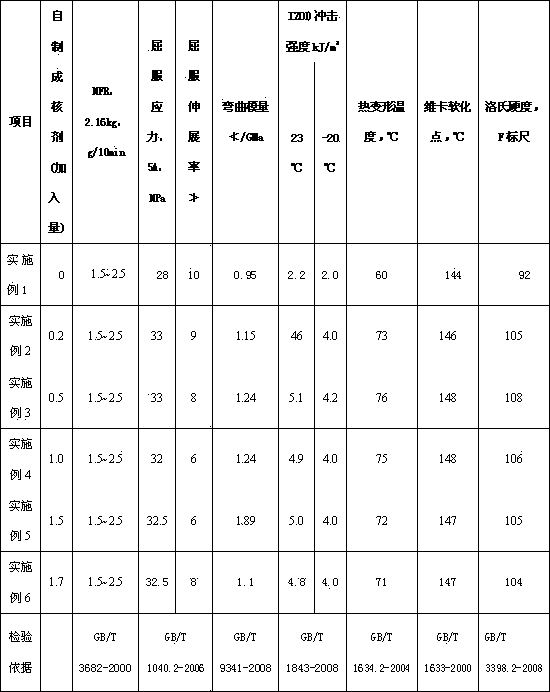

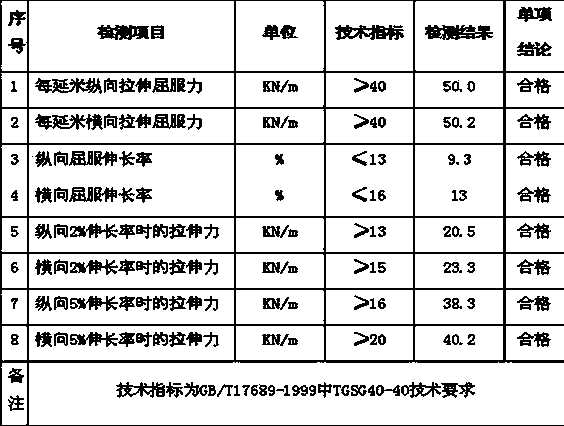

[0018] The present invention selects a self-made modifier, and with different additions, in ordinary polypropylene, synthetic antioxidants, arylamide nucleating agents (self-made nucleating agents) and other series of compounds, by mass ratio 100%: 0.2 %—1.0%: 0.03%—0.05%: 0.05%—0.15% After mixing evenly, the blend is added to a twin-screw extruder that has been heated to 200-230°C, with a screw speed of 60-600 rpm and a heating temperature of It is melt-extruded at 180-230°C to obtain modified polypropylene. After several experiments, the analysis and measurement results show that the modified polypropylene can not only greatly increase the normal temperature impact strength of the base resin, maintain the tensile yield strength, and reduce the tensile yield deformation. Moreover, if the yield tensile strength is not less than 30MPa, the yield strain is less than 9%, and the impact strength is increased by 50%, it is considered effective for modification, and it can be used a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com