Spiral stirrer of vertical type spiral stirring grind

A helical agitator and a technology of helical stirring, which are applied in mixers with rotating stirring devices, chemical instruments and methods, dissolution and other directions, can solve the problems of increased vibration, tail vortex, inconsistency, etc. , The effect of improving casting yield and equipment operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further elaborated below in combination with specific embodiments.

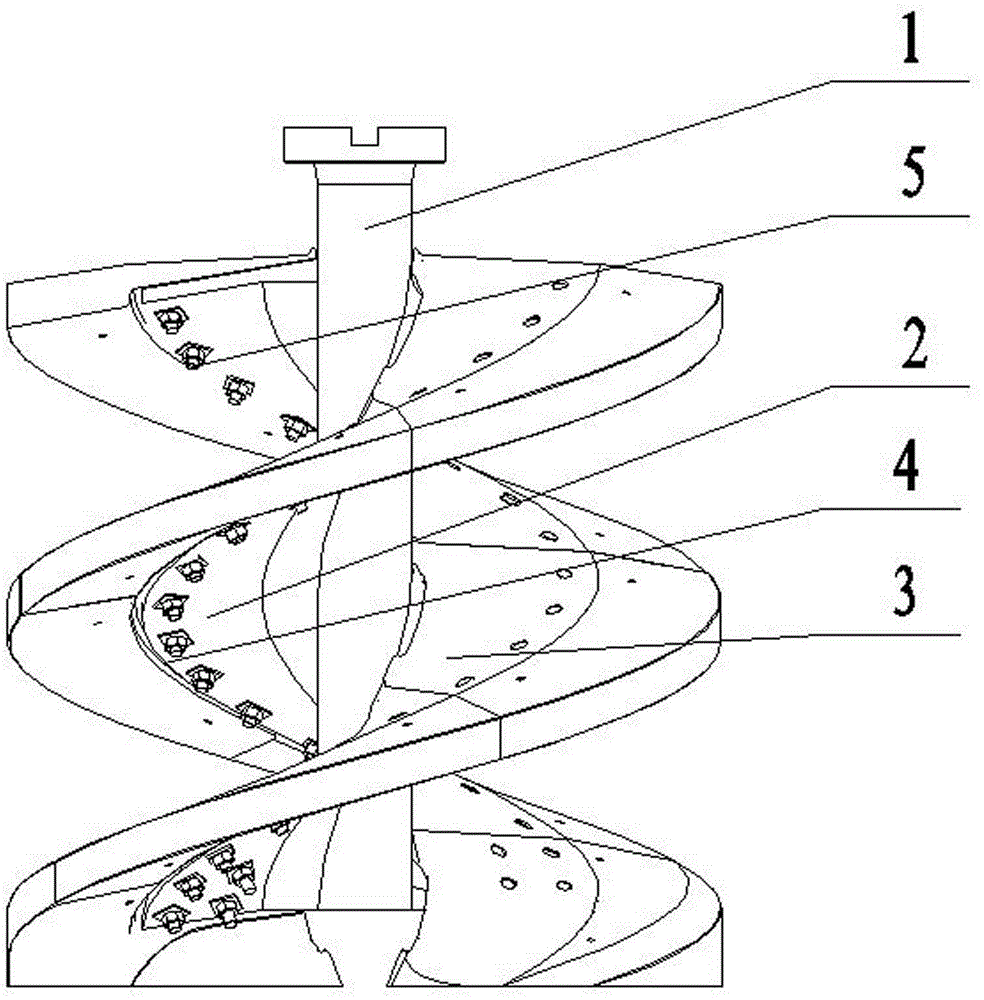

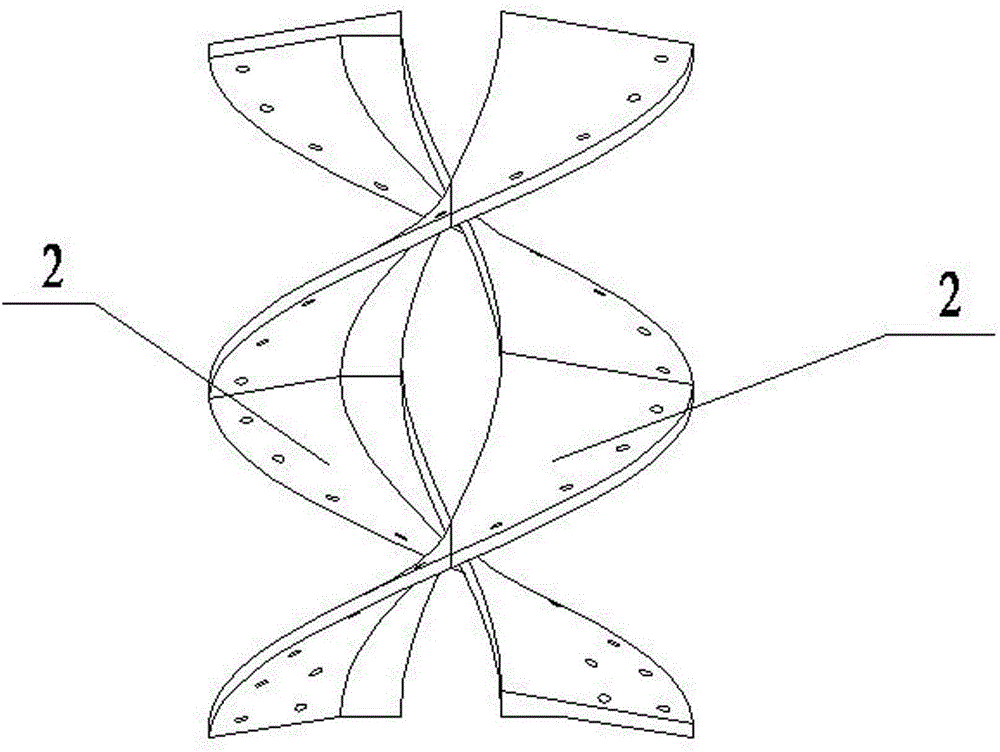

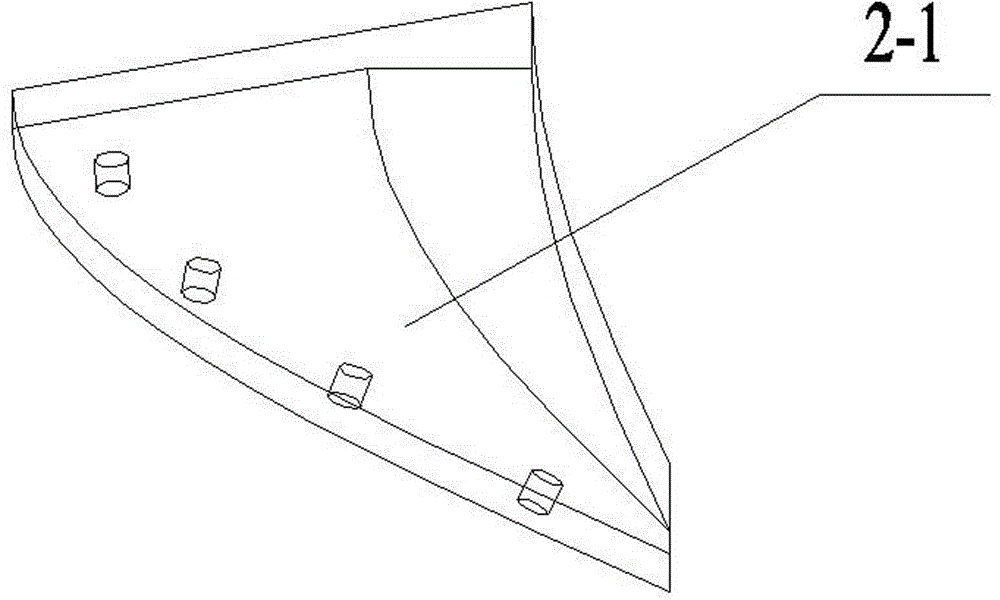

[0037] As shown in the figure: a spiral agitator of a vertical spiral stirring mill is provided with a transmission shaft 1, and a spiral support plate 2 coiled in a spiral shape is provided on the circumferential surface of the transmission shaft 1. The spiral support plate 2 is provided with a spiral liner 3 consistent with its coiled shape. The width of the spiral liner 3 is larger than that of the spiral support 2, and the spiral liner 2 is half-wrapped in it. The spiral liner 3 is characterized by its The pitch diameter of the spiral is the boundary. On the inside of the pitch diameter of the spiral, the angle between the boundary on the normal section and the horizontal plane is 2-3°; on the outside of the pitch diameter of the spiral, the angle between the boundary on the normal section and the horizontal plane is 8-12°. The helix angle at the middle diameter positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com