Preparation method for cadmium sulfide/graphene composite material

A composite material, graphene technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of long preparation cycle, low preparation yield, complicated operation process, etc., and achieve high yield The effect of high, low preparation temperature and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation method of cadmium sulfide / graphene composite material, comprises the steps:

[0023] (1) Add 0.0346 mol of cadmium nitrate and 0.0567 mol of thiourea into 100 mL of deionized water, and stir to obtain a clear solution A.

[0024] (2) Add 0.05 g of graphene oxide into solution A, ultrasonically disperse until uniform, then heat and evaporate the solution at 250 °C until it becomes gelatinous, continue to heat until it burns and releases a large amount of gas, and the obtained product is Cadmium sulfide / graphene composites.

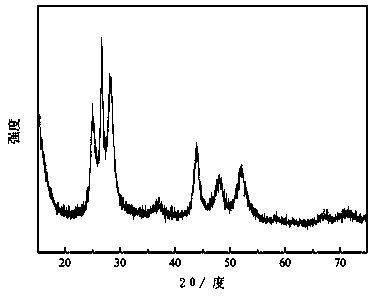

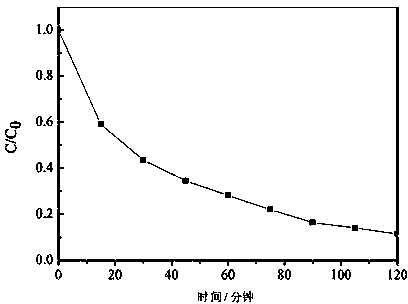

[0025] figure 1 Among them, the X-ray diffraction pattern of the obtained sample is consistent with the peak number and position on the standard PDF card of CdS. It shows that what is obtained is indeed a cadmium sulfide / graphene composite material. Depend on figure 2 It can be seen that after 120 minutes of visible light irradiation, the photocatalytic efficiency of the cadmium sulfide / graphene composite to methylene blue ...

Embodiment 2

[0027] A kind of preparation method of cadmium sulfide / graphene composite material, comprises the steps:

[0028] (1) Add 0.0346 mol of cadmium nitrate and 0.0567 mol of thiourea into 100 mL of deionized water, and stir to obtain a clear solution A.

[0029] (2) Add 0.025 g of graphene oxide into solution A, ultrasonically disperse until uniform, then heat and evaporate the solution at 300 °C until it becomes gelatinous, and continue to heat until it burns and releases a large amount of gas. The obtained product is Cadmium sulfide / graphene composites.

Embodiment 3

[0031] A kind of preparation method of cadmium sulfide / graphene composite material, comprises the steps:

[0032] (1) Add 3.46 mmol of cadmium nitrate and 5.67 mmol of thiourea into 50 mL of deionized water, and stir to obtain a clear solution A.

[0033] (2) Add 0.25 g of graphene oxide into solution A, ultrasonically disperse until uniform, then heat and evaporate the solution at 400 °C until it becomes gelatinous, and continue to heat until it burns and releases a large amount of gas. The obtained product is Cadmium sulfide / graphene composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com