Vertical-type full-automatic filter press based on ultrasonic washing

A fully automatic, filter press technology, applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as low efficiency and poor cleaning effect, and achieve the effect of mature technology, easy implementation and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

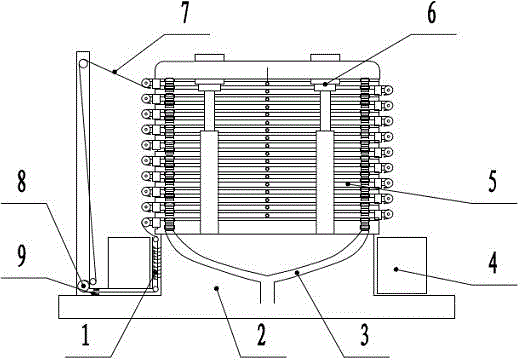

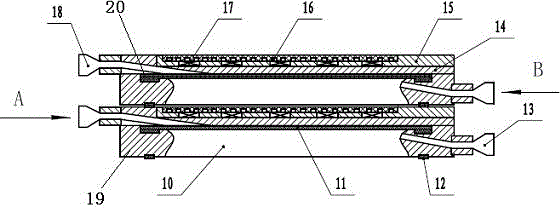

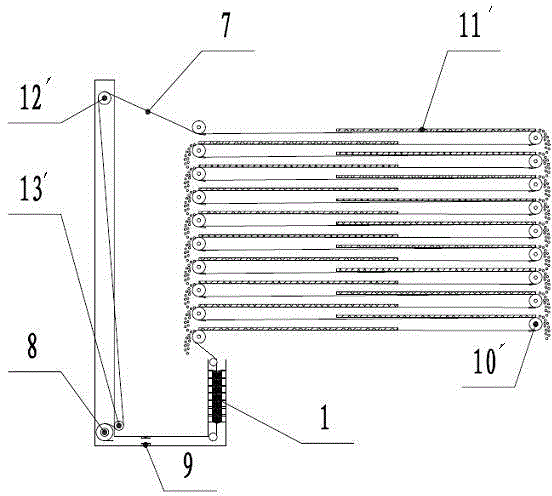

[0024] Such as Figure 1-2 shown.

[0025] A vertical automatic filter press based on ultrasonic washing, mainly composed of frame 2, multiple filter frame groups 5, process pipeline 3, pressing mechanism 6, filter cloth 7, filter cloth driving device 8, filter cloth deviation correction Device 9, filter cloth cleaning device 1, slag hopper 4, washing device and other parts, such as figure 1 shown. The filter press of this embodiment adopts six processes in total: feeding and filtering—first extrusion—ultrasonic washing—secondary extrusion—filter cake drying—unloading. In order to facilitate washing, the pressure of one extrusion should be less than two The pressure of the second extrusion. As one of the key components of the filter press, the filter press frame group 5 is mainly composed of a filter frame plate 14, a filtrate frame 15, a diaphr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com