Powder ridge machine with underneath type main transmission mechanism

A technology of main drive and powder ridge machine, which is applied in the direction of agricultural machinery and implements, tillage tools, applications, etc., can solve the problems of difficult maintenance, large volume and heavy weight of powder ridge machine, and achieve reliable transmission, simple structure, and reduced damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

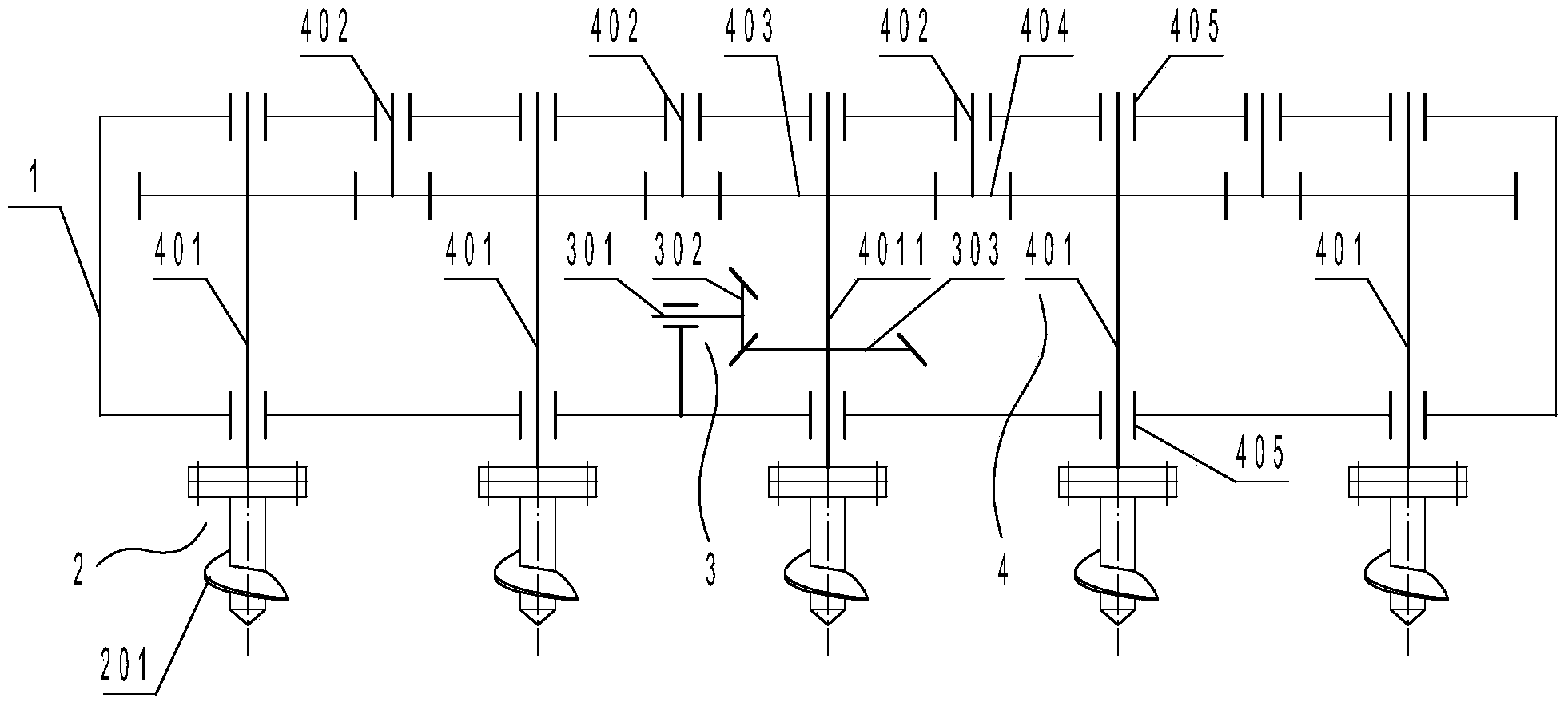

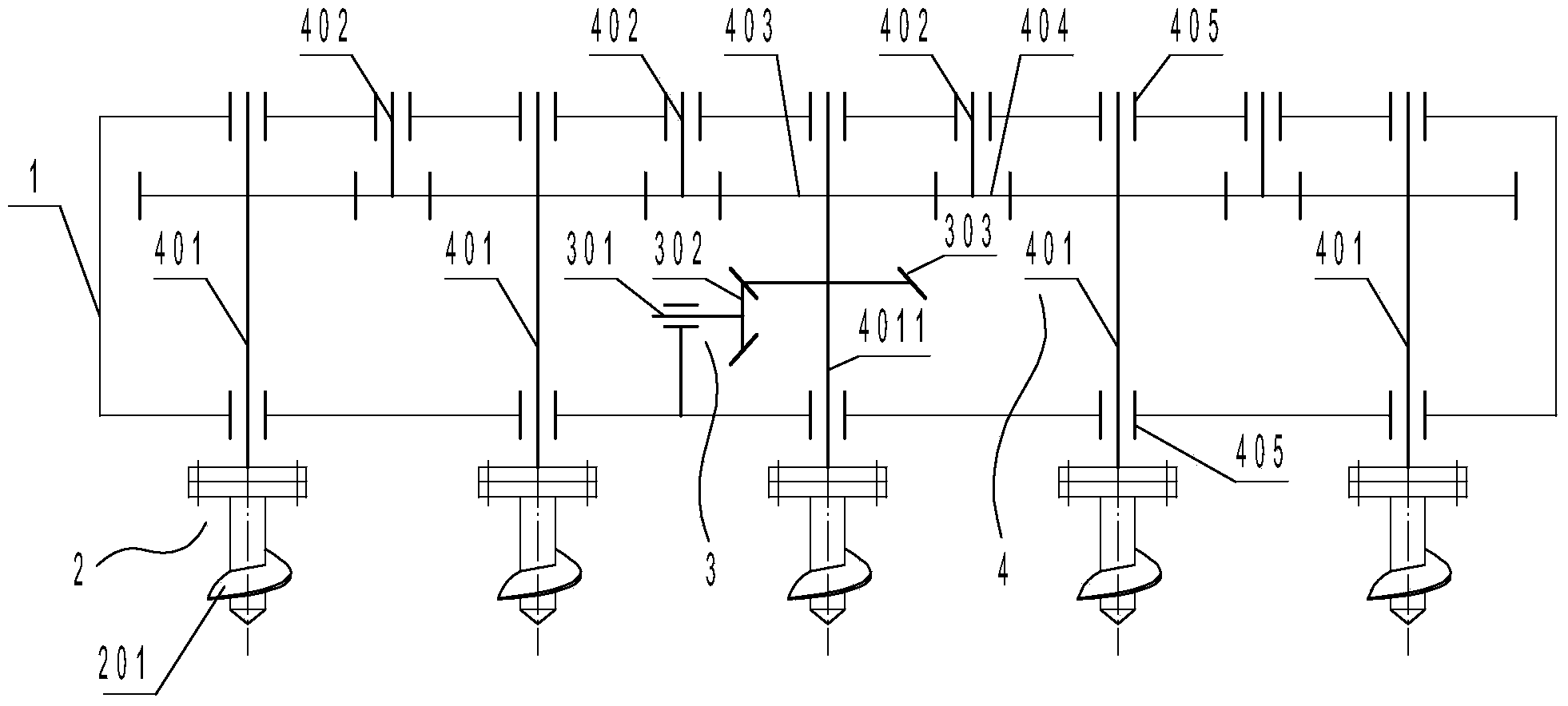

Embodiment 1

[0026] figure 1 Disclosed in is a powder ridge machine with a lower-mounted main transmission mechanism, which includes a closed box 1, 5 rotary cultivators 2, a main transmission mechanism 3 installed in the closed box 1, and an auxiliary transmission mechanism 4. The rotary tiller 2 includes a spiral tillage plowshare 201; the main transmission mechanism 3 includes a power input shaft 301, a driving bevel gear 302 installed on the power input shaft, and a driven bevel gear 303 meshed with the driving bevel gear 302 ; The auxiliary transmission mechanism 4 includes 5 rotary tillage shafts 401 and 4 idler shafts 402, the two ends of the 5 rotary tillage shafts 401 are respectively installed with rolling bearings 405 on the closed box 1, and each rotary tiller shaft The upper part of 401 is equipped with a cylindrical gear 403, and the bottom end of each rotary tiller shaft 401 extends out of the closed box 1 and is connected with the rotary tiller 2 through the connecting fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com