Open direct current brushless motor controller based on six MOS tube power modules

A brushless DC motor, MOS tube technology, applied in the direction of single motor speed/torque control, electronic commutator, etc., can solve the problem of symmetrical load distribution without brushless DC motor controller, high-power brushless DC motor drive capability Insufficient, the performance of the brushless DC motor controller is unstable, etc., to achieve the effect of increasing anti-interference ability, reducing external conductive metal sheets, and realizing intelligent management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

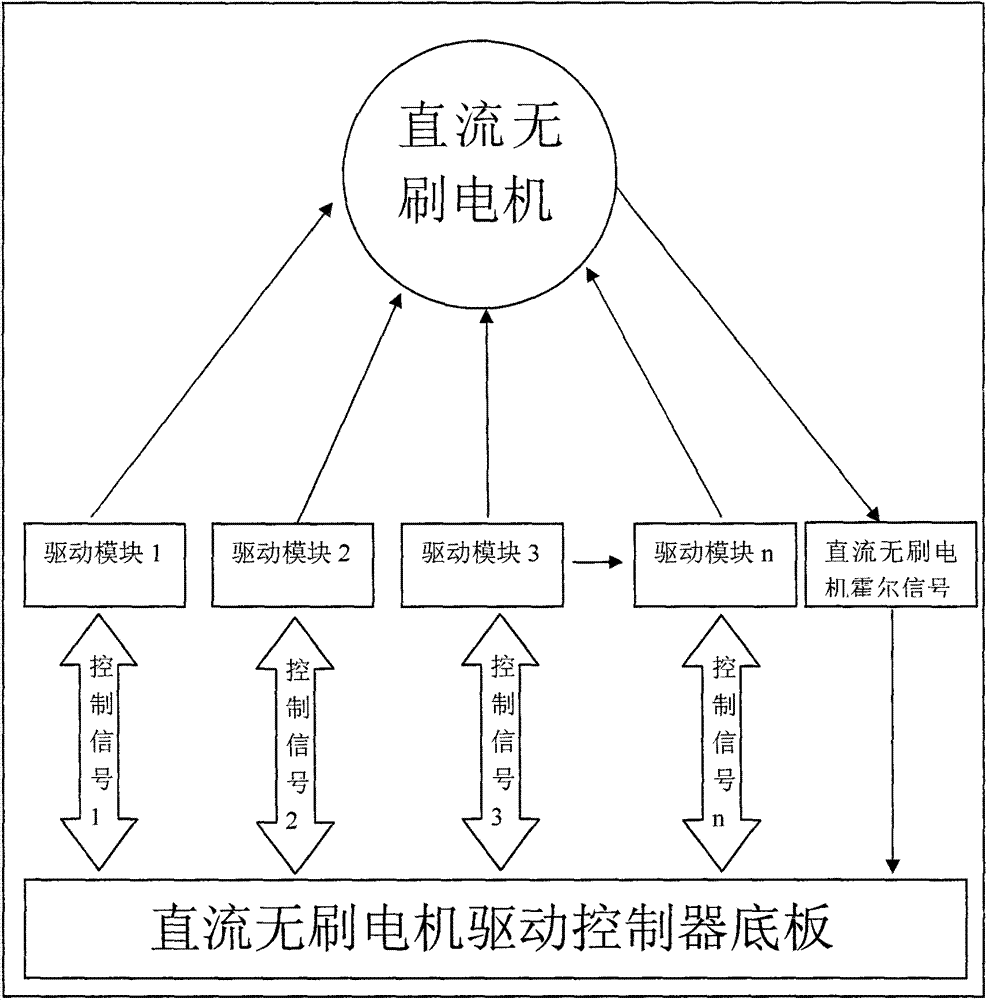

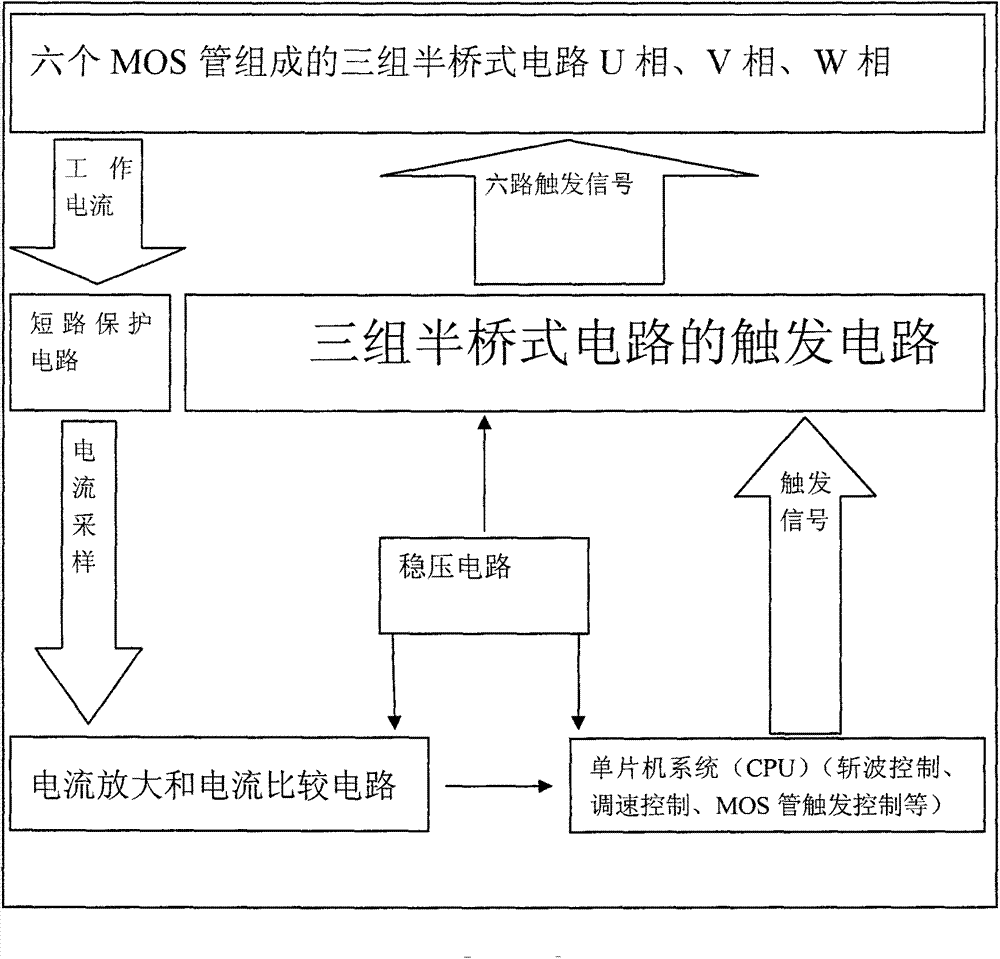

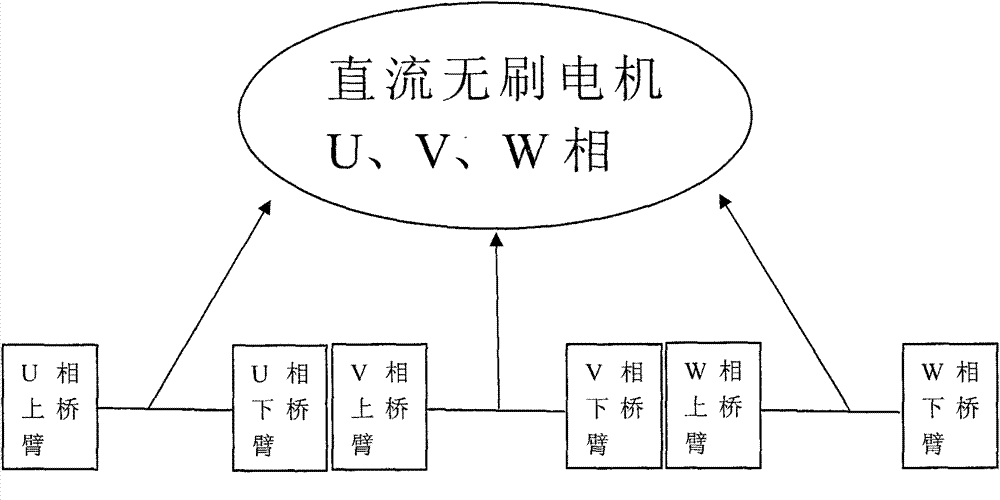

[0054] figure 1 It is separated from the overall layout of the brushless DC motor controller and is mainly divided into small driving modules; figure 2 It is the overall layout of small modules, using strict separation of digital circuits and analog circuits, separation of control circuits and drive circuits, separation between each six-tube drive module, and separation between each six-tube drive module and the main board control module. The six-tube drive module consists of six-tube MOS tubes and six-tube trigger circuits. The six-tube and six-tube trigger circuits are analog circuits, current amplification circuits, current limiting circuits and on-chip system MCUs. Digital control circuits, analog circuits and digital The circuit is divided into regions, and the separated parts are connected by fuses (FUSE), which can be used for overcurrent voltage sampling and short circuit protection. Both the analog part and the digital part adopt chip technology to reduce parasitic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com