A method and device for monitoring etching rate uniformity

A technology of etching rate and strength value, applied in the field of monitoring method and device for uniformity of etching rate, can solve the problems of inability to monitor etching rate in real time, less than 2-3 hours, and labor-intensive cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

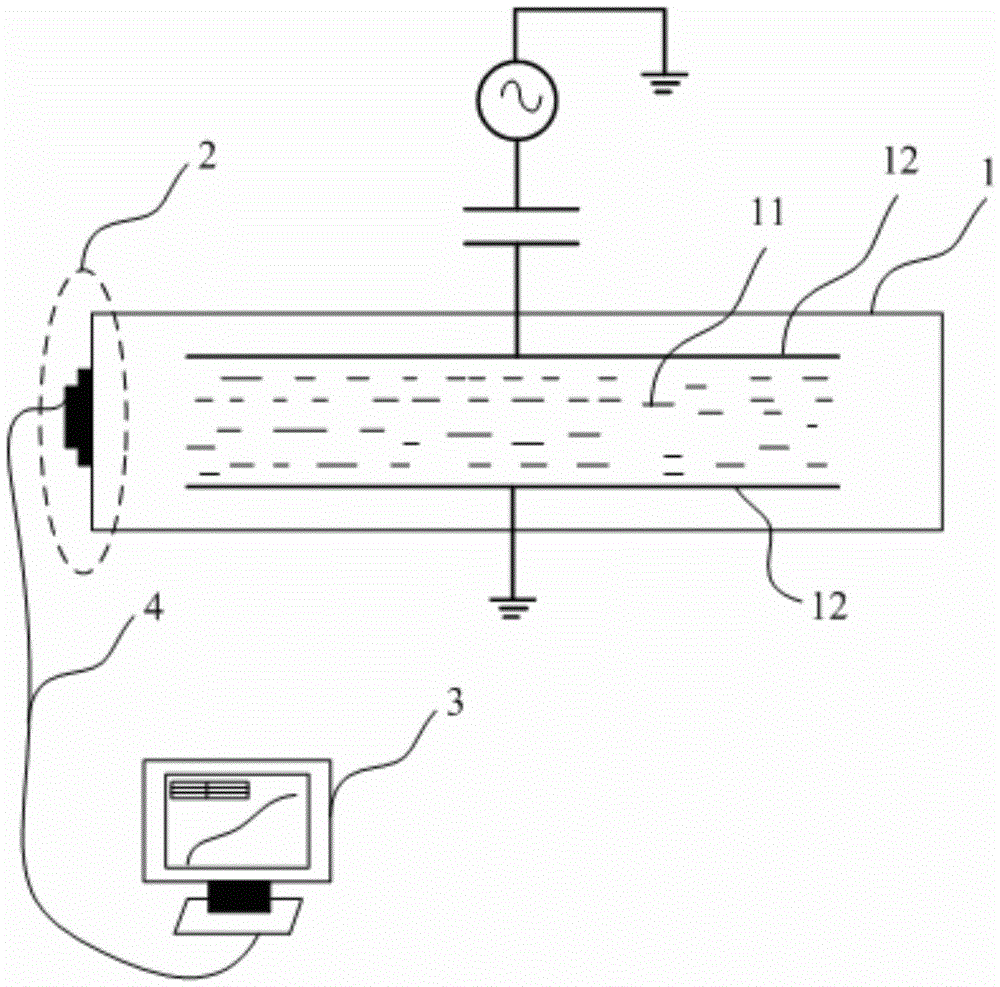

[0074] The embodiments of the present invention provide a method and device for monitoring the uniformity of etching rate, so as to monitor the uniformity of plasma etching rate in an etching reaction chamber in real time.

[0075] The method and device for monitoring etch rate uniformity provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

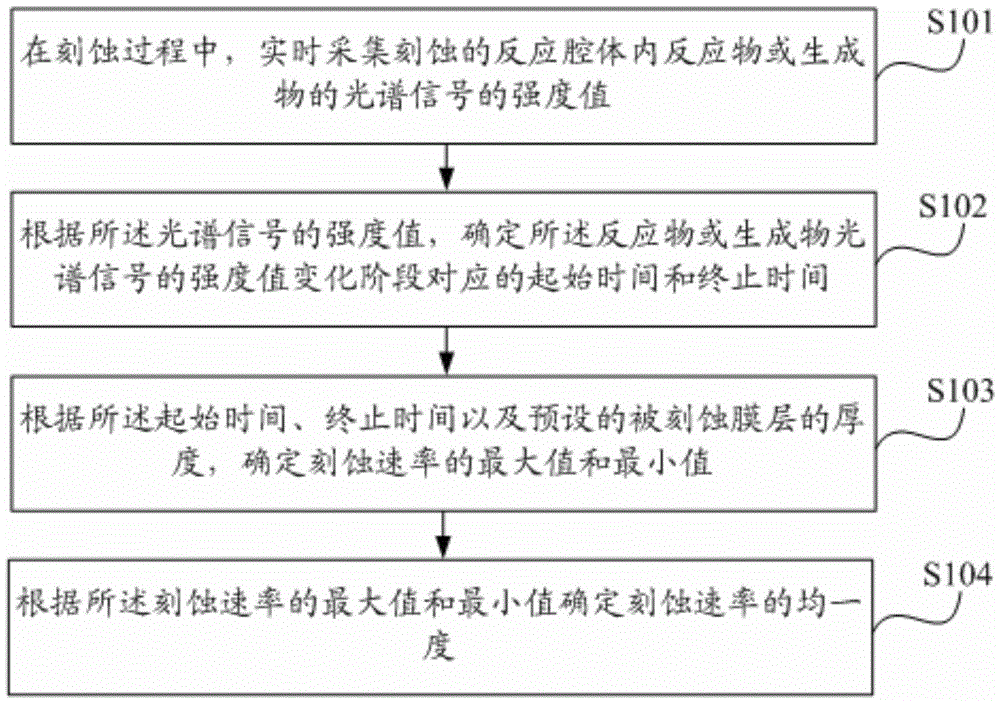

[0076] see figure 1 , a method for monitoring etch rate uniformity provided by an embodiment of the present invention, comprising the following steps:

[0077] S101. During the etching process, collect in real time the intensity value of the spectral signal of the reactant or product in the etched reaction chamber;

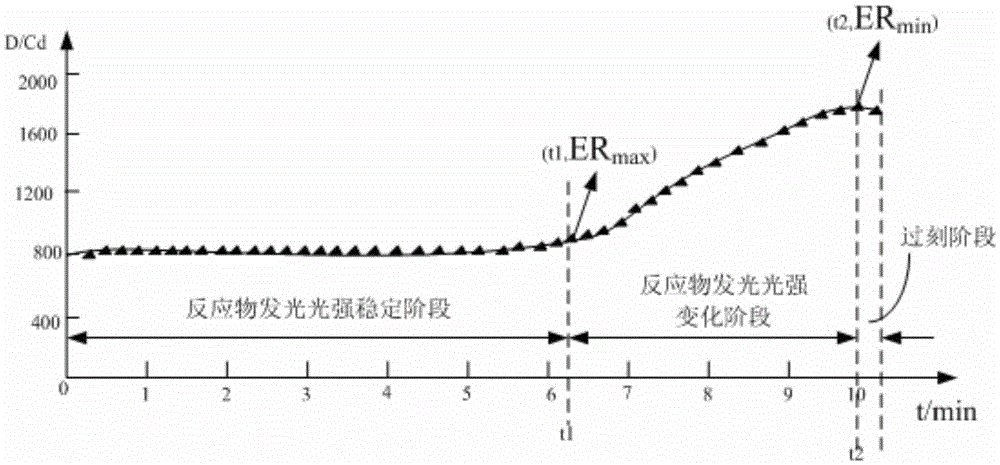

[0078] S102. According to the intensity value of the spectral signal, determine the start time and end time corresponding to the intensity value change phase of the reactant or product spectral signal;

[0079] S103. Determine the maximum and min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com