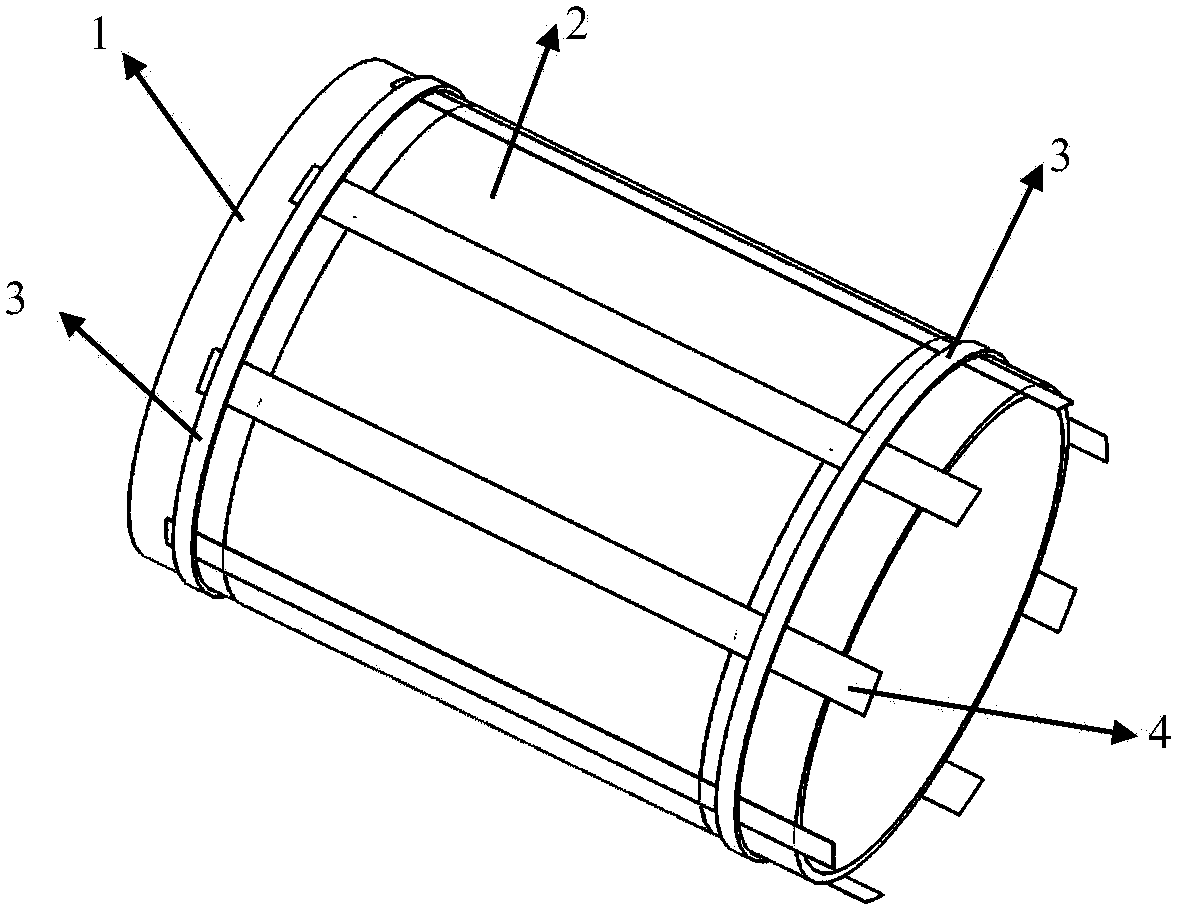

High temperature superconductor coil and winding technology thereof

A high-temperature superconducting and coil technology, applied in superconducting magnets/coils, coil manufacturing, superconducting devices, etc., can solve the problems of reduced performance of superconducting coil devices, burning of superconducting coils, etc., to avoid internal joint failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

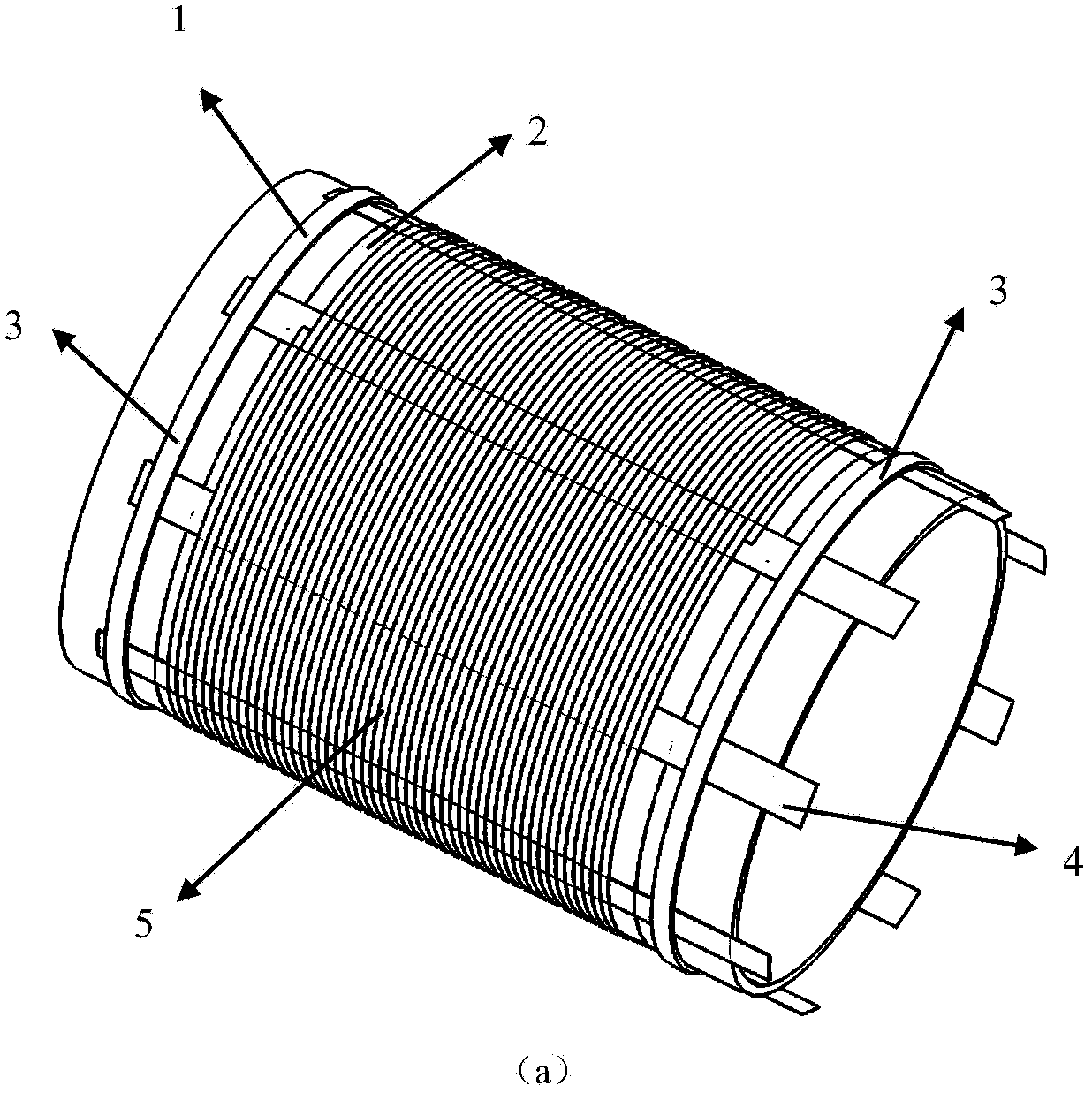

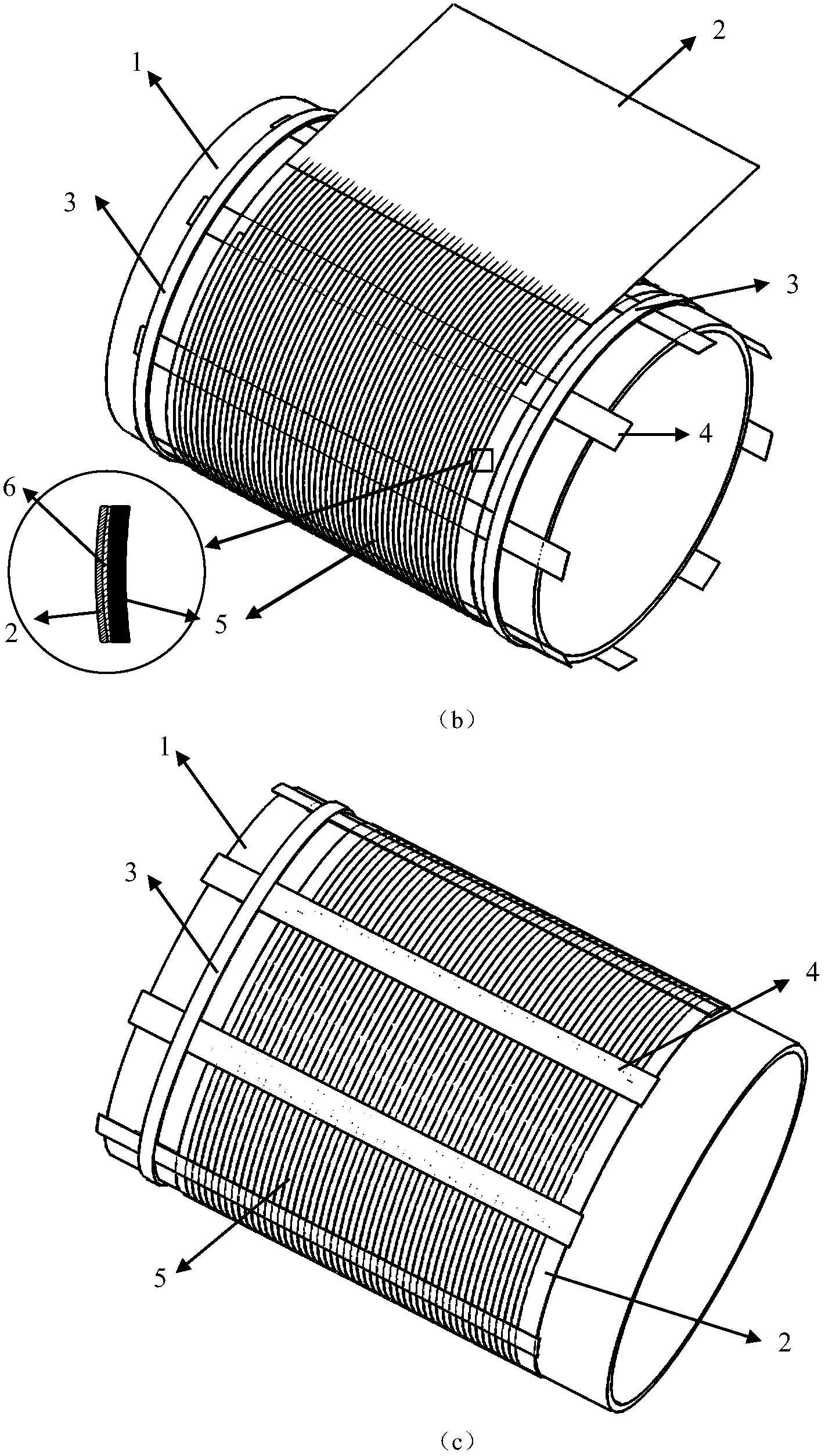

[0021] In the present invention, when the amount of strip material required for winding the coil is small, the solenoid coil mode is used to avoid the connection between the coils, and a single strip material (or double parallel winding) is used for direct winding. Make the winding process more convenient and will not cause damage to the strip. The specific winding method is layered winding, and the selected superconducting tape is wrapped with a polyimide film half-fold to ensure inter-turn insulation; when each layer of coil is wound, a layer of Polyimide film is used to ensure the insulation between layers and prevent the superconducting layer from deforming and falling off; low-temperature glue is used to fix the inter-turns, and a layer of low-temperature glue is evenly applied to the superconducting layer for each winding layer; The polyimide film (belt shape) is used for inter-fixation, and the polyimide film is evenly distributed along the circumference of the skeleton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com