A Method for Manufacturing Different Curvatures of Heliostat Mirror Surfaces

A heliostat and curvature technology, applied in installation, optics, instruments, etc., can solve the problem of inability to meet the design requirements of large-area heliostat mirror field, and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

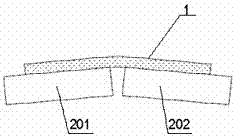

[0034] Embodiment one: if figure 1 As shown, in this embodiment, the curvature surface of the heliostat mirror surface of the mold platform is a curved surface of a specific radian formed by the combination of two surfaces 201 and 202, so that the mirror surface of the heliostat 1 is flattened with the mold platform of the group, and a specific surface is produced. arc surface.

Embodiment 2

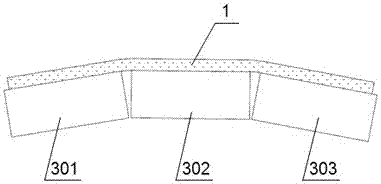

[0035] Embodiment two: if figure 2 As shown, the curvature surface of the heliostat mirror surface of the mold platform in this embodiment is composed of three surfaces 301, 302, and 303 combined to form a curved surface with a specific radian, so that the mirror surface of the heliostat 1 is flattened with the mold platform of this group , making a specific arc.

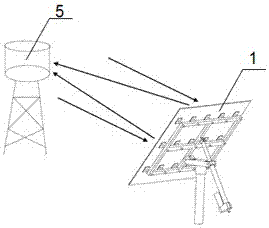

[0036] Such as image 3 As shown, after the single-sided heliostat 1 provided by Embodiment 1 and Embodiment 2 is flattened with the mold platform and successfully manufactured, the sun’s parallel light is converged to the heat absorber 5 to form a relatively concentrated light spot, thereby realizing mirror convergence. light effect.

Embodiment 3

[0037] Embodiment Three: In this embodiment, the heliostat includes a multi-faceted reflector, such as Figure 4 As shown, the heliostat 1 is composed of multi-faceted reflectors, for example, it may be composed of four-faced reflectors 101, 102, 103, 104 in this embodiment, but it is not limited thereto. In this embodiment, the curvature surface of the heliostat mirror surface of the mold platform is a curved surface with a specific radian formed by the combination of four surfaces 401, 402, 403, and 404, so that the mirror surfaces of the heliostats 101, 102, 103, and 104 are respectively in line with the set of molds. The four surfaces 401, 402, 403, 404 of the platform are flattened to form a specific arc.

[0038] Such as Figure 5 As shown, after the multi-faceted heliostat 1 in the third embodiment is flattened with the mold platform, the sun's parallel light is converged to the heat absorber 5 to form a relatively concentrated light spot, thereby achieving the effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com