Recoiling product detection method, recoiling product detection device and recoiling product detection system

An inspection method and inspection device technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as hindering the improvement of high-speed production efficiency and wasting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

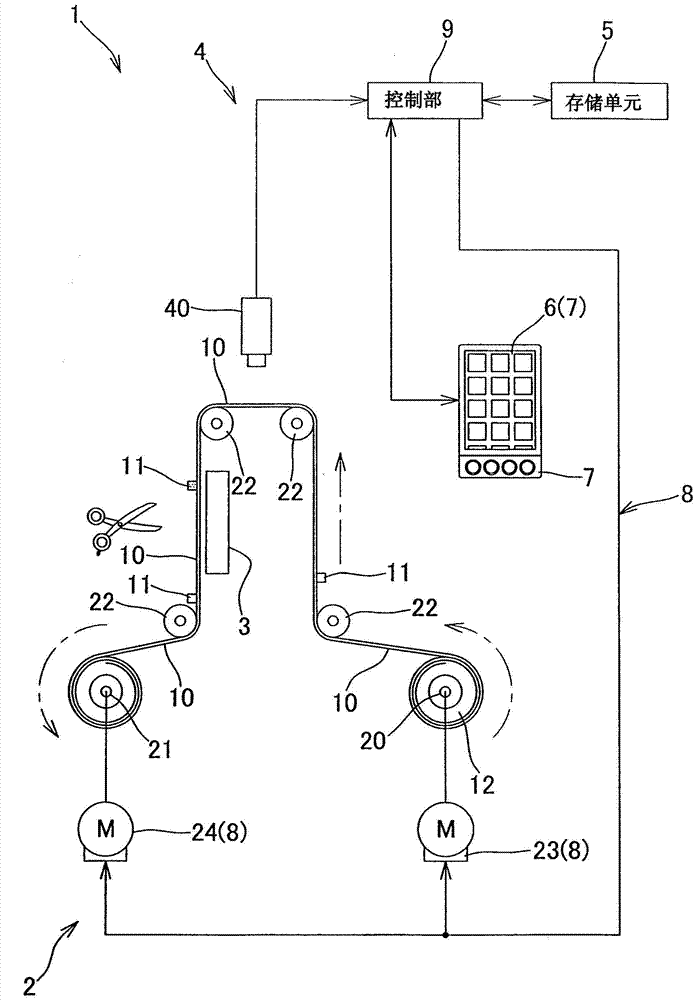

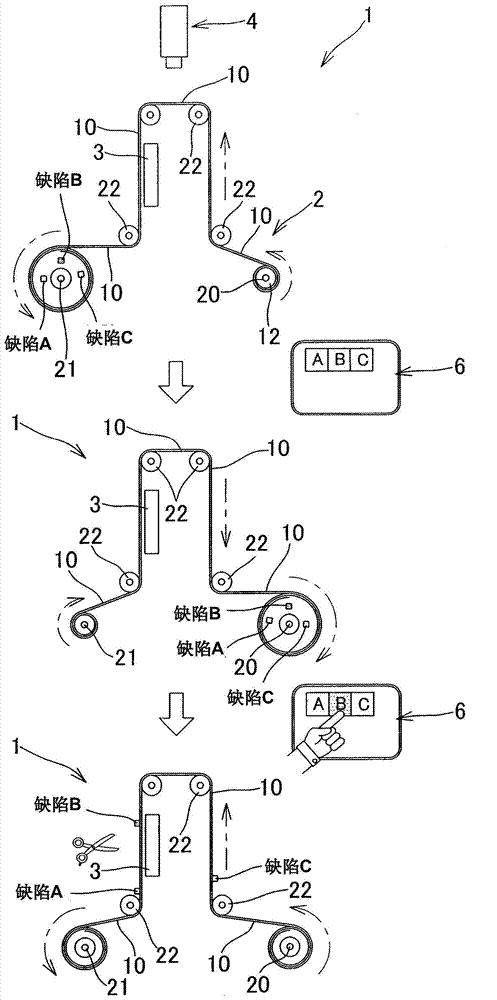

[0148] Such as figure 1 As shown, the rewinding product inspection device 1 of this embodiment includes: a rewinding mechanism 2 for guiding the movement of the rewinding sheet 10 and performing a rewinding action; and an inspection for the operator to visually confirm defects on the rewinding sheet 10 Station 3; inspection unit 4 for inspecting the rewinding sheet 10, detecting defects and their position on the winding sheet; for the image of the defect 11 detected by the inspection unit 4 and its position on the winding sheet 10 The storage unit 5 for storing the location; the display unit 6 for displaying the images of the stored defective parts 11 in a list; the operation unit 7 for the operator to specify any defective part among the defective parts displayed by the display unit 6; and After the winding is completed, the winding sheet 10 is moved, and the designated defective portion 11 is moved to the position of the inspection table 3 based on the position information on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com