Method for detecting apparent defects of O-shaped rubber ring

A technology of appearance defects and detection methods, applied in the direction of optical testing defects/defects, etc., can solve the problems of easy missed inspection and easy visual fatigue, and achieve the effect of improving efficiency, protecting eyes and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

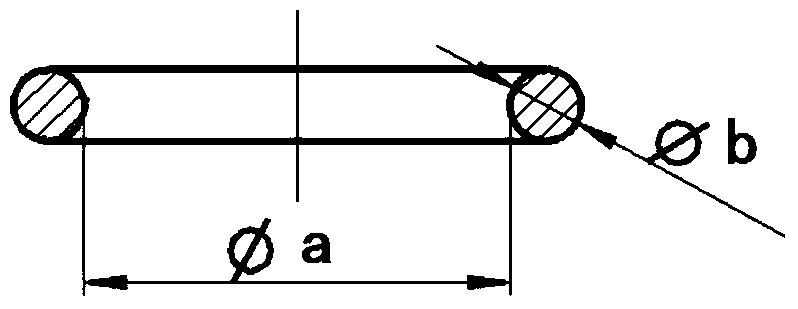

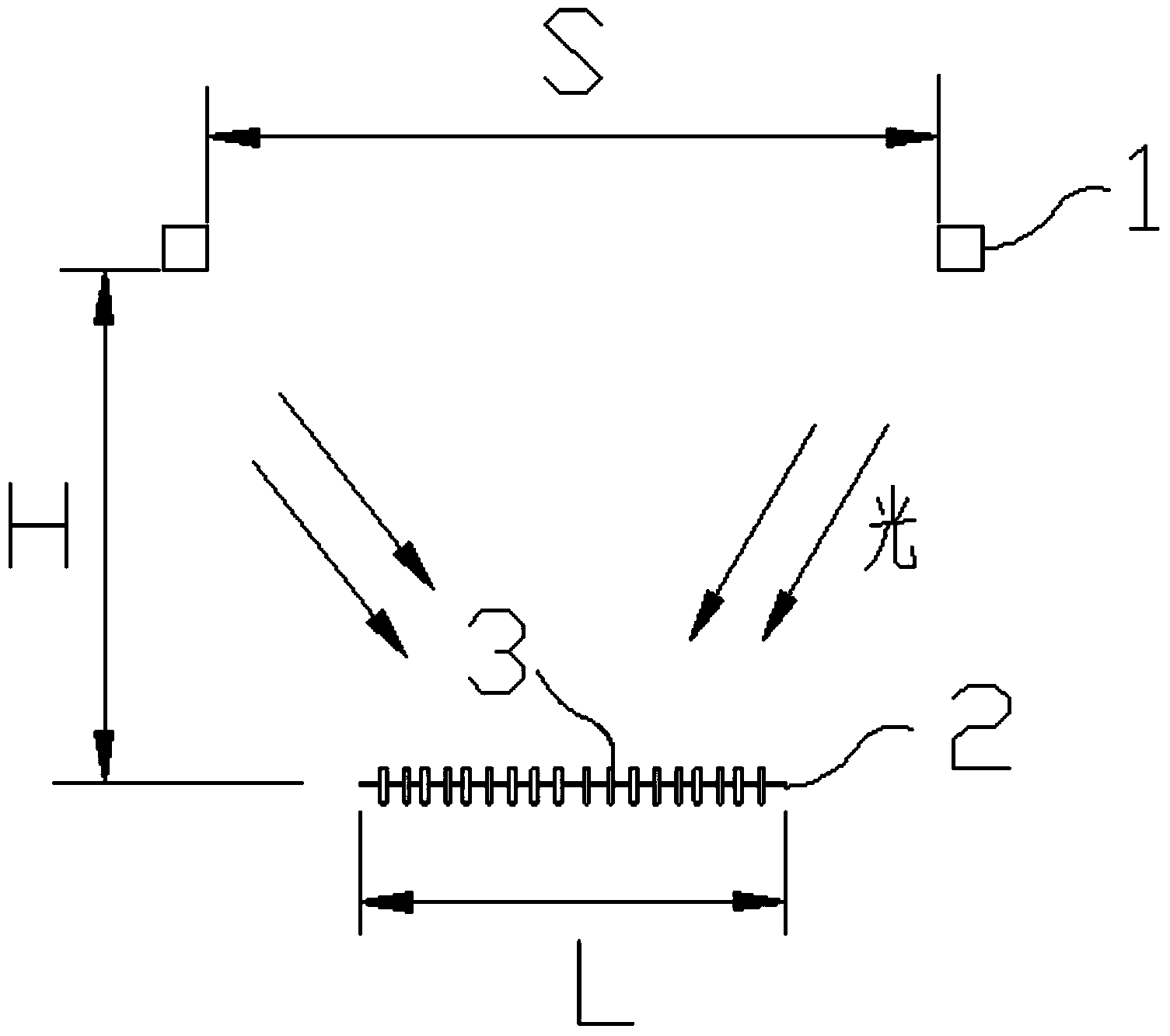

[0033] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a detection method for the appearance defects of O-shaped rubber rings, for figure 1 Inner diameter a: ∮11mm, wire diameter b: ∮2.5mm O-shaped rubber ring for inspection, the steps are:

[0034] (1) Condition preparation, install two parallel fluorescent lamps 1, the light emitted by the fluorescent lamps 1 is white light, the illuminance F of the fluorescent lamps 1 is 6800lux, and the distance between the two fluorescent lamps 1 is S; prepare two plastic plates, one for A flat plate with a groove in the middle. The color of the plastic plate is represented by the CIE1976 color system: L* is 75, a* is -23, and b* is 60; the overall dimensions of the plastic plate are 300mm in length, 260mm in width, and 3mm in thickness;

[0035] (2) The O-shaped rubber ring 3 to be inspected for appearance is placed in the box to be inspected;

[0036] (3) Put the O-shaped rubber ring 3 in the box of the product to ...

Embodiment 2

[0043] Same as Example 1, the difference is: this example is to detect the O-shaped rubber ring with inner diameter a:∮5.5mm and wire diameter b:∮1.5mm; the illuminance F of the fluorescent lamp 1 is 7400lux; the color of the plastic plate is based on CIE1976 The color system indicates: L* is 71, a* is -15, b* is 45; H is selected as 1.2m, and workers need to work continuously for A equal to 4. The method of the workers in Example 1 is reversed, that is, the second group adopts the method of the present invention, and the first group adopts the working method of its original factory.

[0044] After 4 hours of work, 16 of the workers in the first group experienced visual fatigue such as sore eyes, and the average number of O-shaped rubber rings 3 detected by each person was 1,735. During the re-inspection, a total of 207 pieces were missed. , there are 10.35 missed inspections per person on average, and the missed inspection rate is 0.6%. Among these 207 pieces, 153 pieces are ...

Embodiment 3

[0046] Same as Example 1, the difference is: this example is to detect the O-shaped rubber ring with inner diameter a:∮2mm and wire diameter b:∮1.5mm; the illuminance F of the fluorescent lamp 1 is 6300lux; the color of the plastic plate is CIE1976 color The system indicates: L* is 79, a* is -30, b* is 75; H is selected as 0.8m, and workers need continuous working hours A equal to 2.

[0047] After 2 hours of work, 2 of the workers in the second group experienced visual fatigue such as sore eyes. The average number of O-shaped rubber rings 3 detected by each person was 937. During the re-inspection, it was found that a total of 78 pieces were missed. , each person has 3.9 missed inspections on average, and the missed inspection rate is 0.4%. Among these 78 pieces, 45 pieces are concave-convex defects at the parting surface, and 33 pieces are flow marks on the sealing surface; In the first group of the method, the average number of O-shaped rubber rings 3 detected by each perso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com