Engine fuel consumption measurement device and measurement method

A technology of fuel consumption and measurement devices, which is applied in the direction of measurement devices, relative volume flow measurement, liquid/fluid solid measurement, etc. It can solve the problems of small engine oil return flow rate, inability to measure accurately, and low precision, so as to solve the problem of oil return The effects of pulsation, good real-time measurement and advanced control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

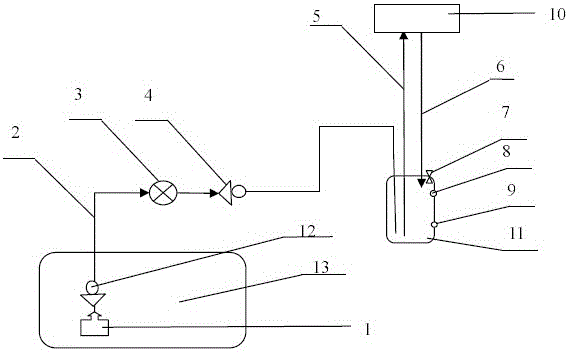

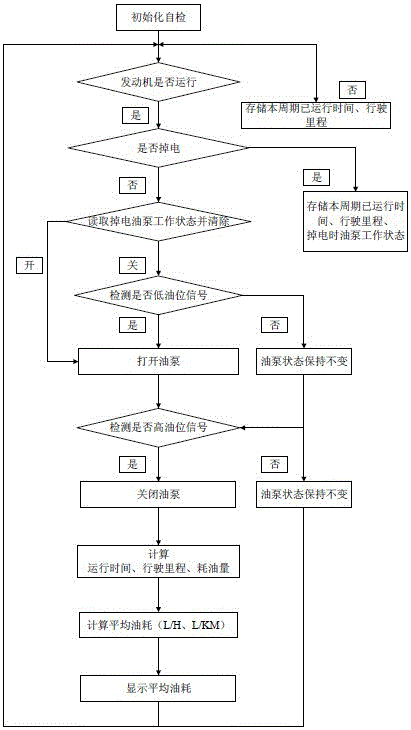

[0048] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described. The engine fuel consumption measurement device is used in automobile engines.

[0049] Such as figure 1 Shown: electric oil pump 1, oil pipe 2, flow sensor 3, first check valve 4, engine oil inlet pipe 5, engine oil outlet pipe 6, vent hole 7, high liquid level sensor 8, low liquid level sensor 9, engine 10 , Auxiliary oil tank 11 and one-way valve 12 composition. The fuel goes to the auxiliary fuel tank 11 through the electric oil pump 1, the second check valve 12, the oil pipe 2, the flow sensor 3, and the first check valve 4. The engine oil outlet pipe 6 returns to the auxiliary fuel tank 11 .

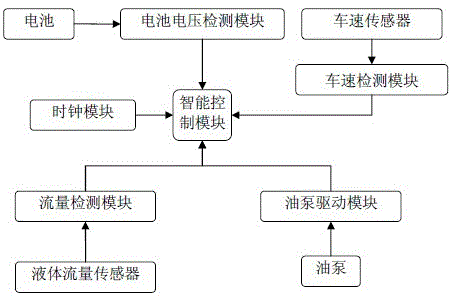

[0050] Such as figure 2 Shown: The controller module includes a battery voltage detection module, a vehicle speed detection module, a flow detection module, an oil pump drive module, an intelligent control modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com