Drying process of sulfonate

A drying process and sulfonate technology, applied in drying solid materials, heating to dry solid materials, drying and other directions, can solve the problems of long drying time and difficult temperature control of sulfonate, achieve process requirements and more energy saving , the effect of clearly marked and neatly arranged lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

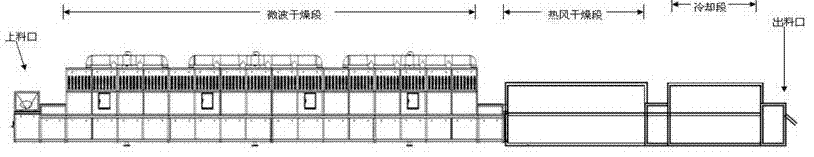

[0030]A kind of drying process of sulfonate, its step is as follows:

[0031] (1) Microwave drying stage: Evenly distribute the paste sulfonate with an active substance concentration of 65% and a moisture content of 35% on the conveyor belt and enter the microwave dryer. The microwave drying temperature is 103°C, and the paste sulfonate The thickness of the material is 2mm, the drying time is 4 minutes, the material of the conveyor belt is polytetrafluoroethylene, the microwave frequency of the microwave dryer is 2400-2500 MHz, the microwave power is 100 KW, the length of the microwave section is 8m, and the water content is 5.5 % of sulfonate;

[0032] (2) Hot air drying stage: put the sulfonate with a water content of 5.5% into the hot air dryer, the temperature of the hot air drying is 122°C, and the air volume is 100 m 3 / h, drying time 2 min, the length of the hot air section is 4 m, obtain the sulfonate with water content≤1%;

[0033] (3) Cold air cooling stage: the co...

Embodiment 2

[0035] A kind of drying process of sulfonate, its step is as follows:

[0036] (1) Microwave drying stage: Evenly distribute the paste sulfonate with an active substance concentration of 55% and a water content of 45% on the conveyor belt and enter the microwave dryer. The microwave drying temperature is 117°C, and the paste sulfonate The thickness of the material is 1.5 mm, and the time is 6 minutes. The material of the conveyor belt is polytetrafluoroethylene, the microwave frequency of the microwave dryer is 2400-2500 MHz, the microwave power is 115 KW, and the length of the microwave section is 8m. The water content is 6 % of sulfonate;

[0037] (2) Hot air drying stage: put the sulfonate with a water content of 6% into the hot air dryer, the temperature of the hot air drying is 128°C, and the air volume is 210 m 3 / h, drying time 3 min, described hot air section length is 4 m, obtains the sulfonate of water content≤1%;

Embodiment 3

[0040] A kind of drying process of sulfonate, its step is as follows:

[0041] (1) Microwave drying stage: evenly distribute the paste sulfonate with an active substance concentration of 46% and a water content of 54% on the conveyor belt and enter the microwave dryer. The microwave drying temperature is 135°C, and the paste sulfonate The thickness of the material is 1mm, the time is 8min, the material of the conveyor belt is polytetrafluoroethylene, the microwave frequency of the microwave dryer is 2400-2500 MHz, the microwave power is 130 KW, the length of the microwave section is 12 m, and the water content is 8%. sulfonate;

[0042] (2) Hot air drying stage: put the sulfonate with a water content of 8% into the hot air dryer, the temperature of hot air drying is 136°C, and the air volume is 380m 3 / h, drying time 4min, described hot air section length is 6 m, obtains the sulfonate of water content≤1%;

[0043] (3) Cold air cooling stage: the cold air is clean and dry air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com