Protecting cover for conveying of brick blocks

A technology of protective cover and brickwork, which is applied in the direction of construction, building structure, and building material processing, etc., and can solve the problems of large vertical transportation volume, falling and hurting people, and large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

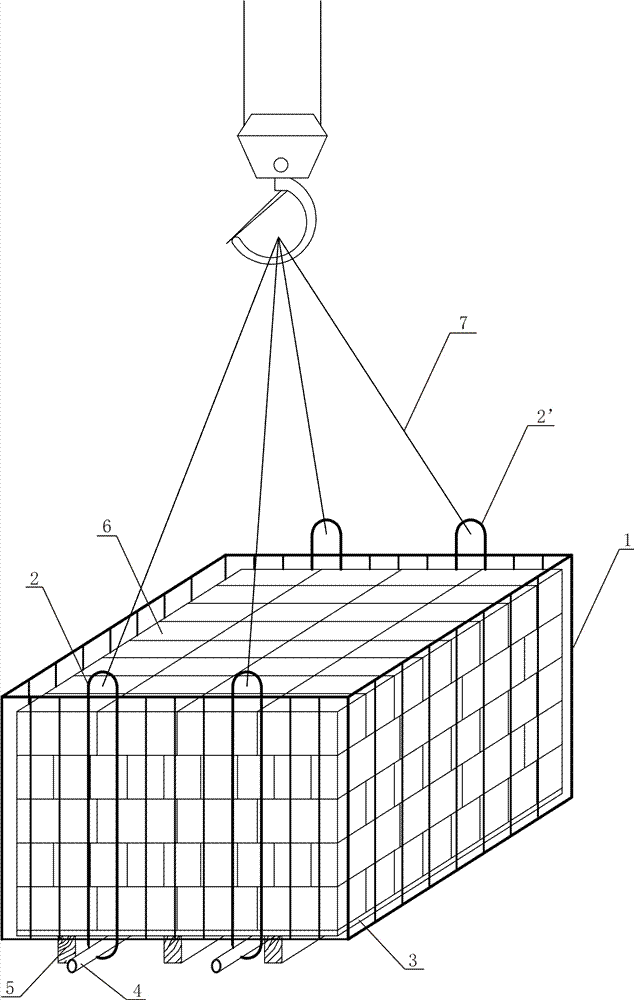

[0012] Such as figure 1 As shown, a kind of protective cover for brick block transportation, the two sides of steel bar covering body 1 are provided with multiple sets of long lifting ring groups 2, 2', the height of the upper end of long hanging ring 2 is higher than the height of the upper end of steel bar covering body 1, and the height of long lifting ring 2 The height of the lower end is lower than the height of the lower end of the reinforcement cage 1, the two ends of the short pipe 4 respectively pass through the lower end of each set of long rings 2, 2', the backing plate 3 is placed on the short pipe 4, and the bottom of the backing plate 3 is provided with a wooden Fang 5, the size of wooden Fang 5 is 50×100cm.

[0013] The steel bar cover body 1 is a cover body made by welding a plurality of steel bars.

[0014] The backing plate 3 is a wooden backing plate with a thickness of 3-15mm.

[0015] The short pipe 4 is a short steel pipe.

[0016] The quantity of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap