A collecting bucket for metal grinding and cutting waste powder

A collection bucket, grinding and cutting technology, applied in the field of collection bucket, can solve the problems of easy cut hands, etc., achieve good dust removal effect, prevent air pollution, and prevent cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

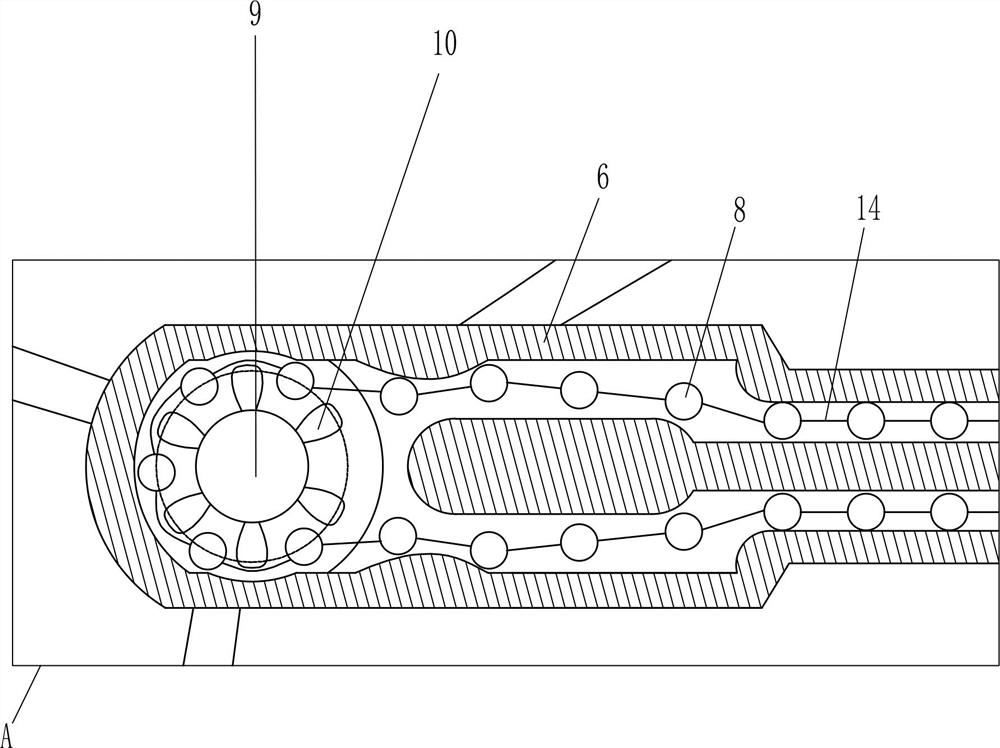

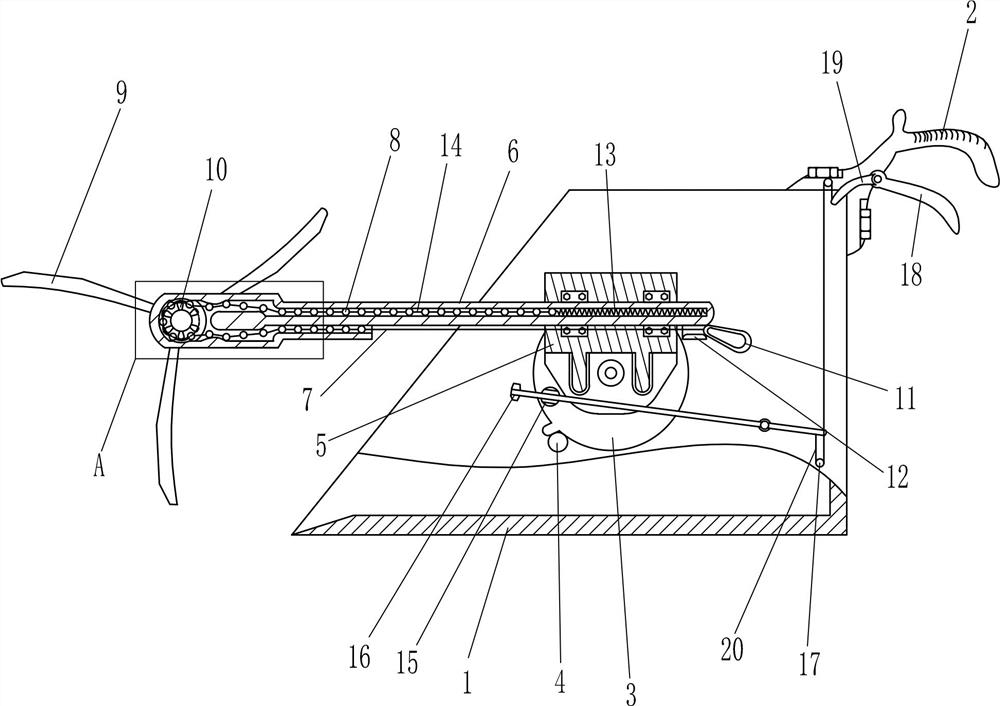

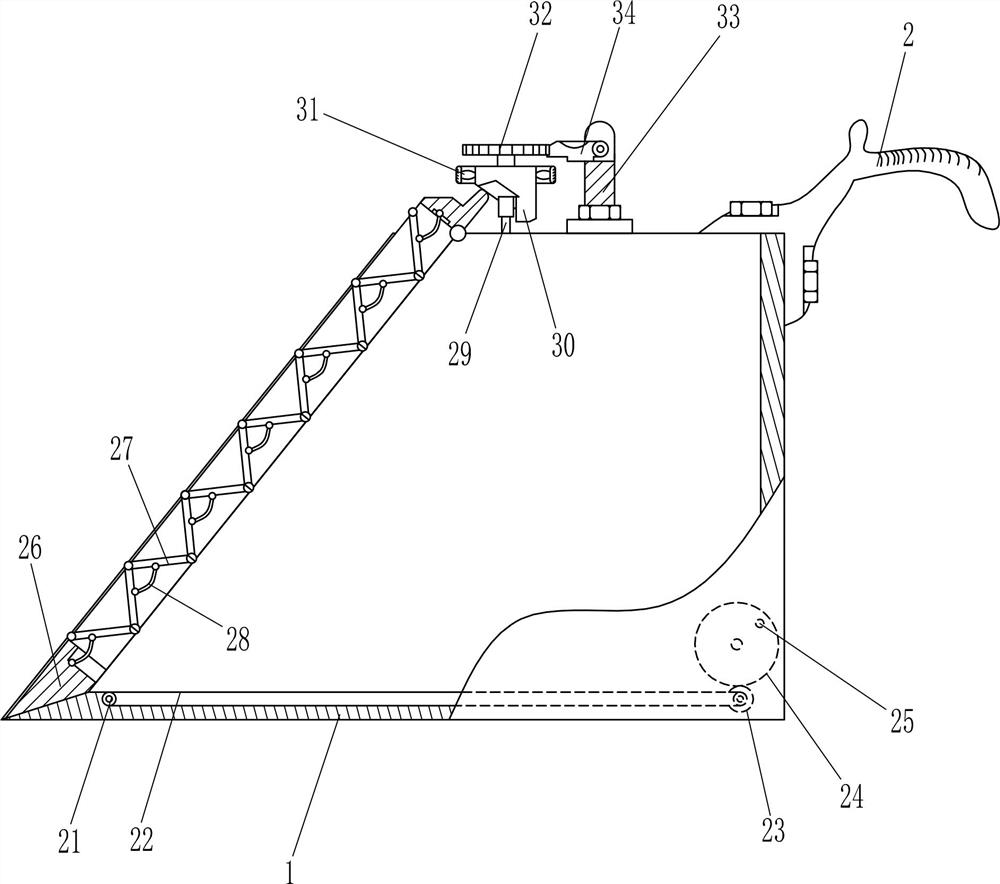

[0021] A kind of collecting bucket for metal grinding and cutting waste powder, such as Figure 1-3 As shown, it includes a collection bucket 1, a first handle 2, a first mounting base 3, a fixed rod 4, a placement plate 5, a connecting frame 6, a first steel wire rope 7, a steel ball 8, a rotating collection rake 9, a fixed block 10, a pull The ring 11, the first guide sleeve 12, the spring 13 and the second wire rope 14, the first handle 2 is connected to the upper right side of the collection bucket 1, the first mounting seat 3 is connected to the middle part of the front side of the collection bucket 1 in a rotating manner, and the front side of the collection bucket 1 The lower part is connected with a fixed rod 4, and the fixed rod 4 is stuck on the lower left side of the first mounting seat 3. The upper part of the front side of the first mounting seat 3 is connected with a placement plate 5, and the front side of the placement plate 5 is connected with a connecting fram...

Embodiment 2

[0023] A kind of collecting bucket for metal grinding and cutting waste powder, such as Figure 1-3 As shown, it includes a collection bucket 1, a first handle 2, a first mounting base 3, a fixed rod 4, a placement plate 5, a connecting frame 6, a first steel wire rope 7, a steel ball 8, a rotating collection rake 9, a fixed block 10, a pull The ring 11, the first guide sleeve 12, the spring 13 and the second wire rope 14, the first handle 2 is connected to the upper right side of the collection bucket 1, the first mounting seat 3 is connected to the middle part of the front side of the collection bucket 1 in a rotating manner, and the front side of the collection bucket 1 The lower part is connected with a fixed rod 4, and the fixed rod 4 is stuck on the lower left side of the first mounting seat 3. The upper part of the front side of the first mounting seat 3 is connected with a placement plate 5, and the front side of the placement plate 5 is connected with a connecting fram...

Embodiment 3

[0026] A kind of collecting bucket for metal grinding and cutting waste powder, such as Figure 1-3As shown, it includes a collection bucket 1, a first handle 2, a first mounting base 3, a fixed rod 4, a placement plate 5, a connecting frame 6, a first steel wire rope 7, a steel ball 8, a rotating collection rake 9, a fixed block 10, a pull The ring 11, the first guide sleeve 12, the spring 13 and the second wire rope 14, the first handle 2 is connected to the upper right side of the collection bucket 1, the first mounting seat 3 is connected to the middle part of the front side of the collection bucket 1 in a rotating manner, and the front side of the collection bucket 1 The lower part is connected with a fixed rod 4, and the fixed rod 4 is stuck on the lower left side of the first mounting seat 3. The upper part of the front side of the first mounting seat 3 is connected with a placement plate 5, and the front side of the placement plate 5 is connected with a connecting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com