Water-based synthetic leather, and production line and production method thereof

A production method and technology of synthetic leather, applied in chemical instruments and methods, layered products, textiles and papermaking, etc., can solve the problems of rough temperature control scheme, inaccurate temperature control, low drying efficiency, etc., to solve color difference, Avoid low drying efficiency and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

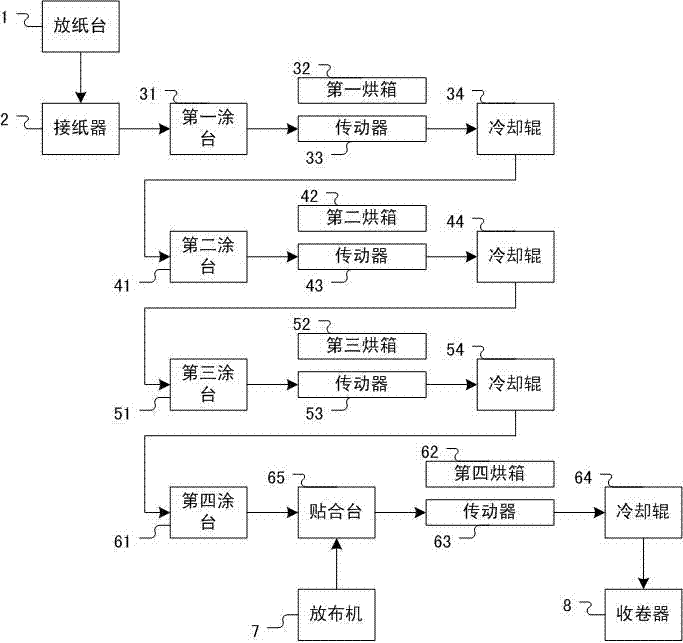

Method used

Image

Examples

Embodiment 1

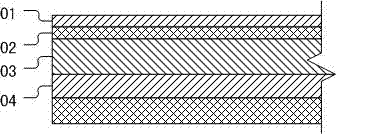

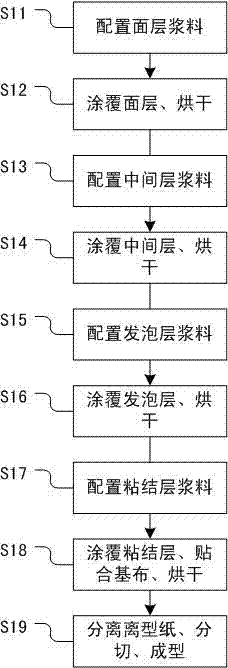

[0048] S11: configuring surface layer slurry. In terms of weight percentage, the surface layer slurry is composed of 35 parts of water-based polyurethane resin (surface layer water-based polyurethane resin, model: MCKT-725A), 65 parts of water, 0.8 parts of thickener, 0.3 parts of defoamer, 0.3 parts of fluid It is composed of leveling agent, 1 part of external linking agent and 3.2 parts of water-based color paste. This component is thickened and compounded under the stirring of the disperser, and the viscosity is adjusted to 2000cps / 20°C to become the surface layer slurry for synthetic leather.

[0049] S12: coating the surface layer slurry on a release paper to form a water-based resin surface layer, and drying the water-based resin surface layer. The release paper uses DE90 release paper produced by Warren Company of the United States, the coating thickness is 5 wires, and the transmission speed of the actuator in the first oven is 10m / min.

[0050] S13: configuring middl...

Embodiment 2

[0058] S21: configuring surface layer slurry. In terms of weight percentage, the surface layer slurry is composed of 30 parts of water-based polyurethane resin (surface layer water-based polyurethane resin, model: MCKT-725A), 65 parts of water, 1 part of thickener, 0.3 part of defoamer, 0.5 part of fluid It is composed of leveling agent, 1 part of external linking agent and 3.2 parts of water-based color paste. This component is thickened and compounded under the stirring of the disperser, and the viscosity is adjusted to 2100cps / 20°C to become the surface layer slurry for synthetic leather.

[0059] S22: coating the surface layer slurry on a release paper to form a water-based resin surface layer, and drying the water-based resin surface layer. The release paper uses DE90 release paper produced by Warren Company of the United States, the coating thickness is 5 wires, and the transmission speed of the actuator in the first oven is 12m / min.

[0060] S23: configuring middle lay...

Embodiment 3

[0068] S31: configuring surface layer slurry. In terms of weight percentage, the surface layer slurry consists of 40 parts of water-based polyurethane resin (surface layer water-based polyurethane resin, model: MCKT-725A), 60 parts of water, 0.5 part of thickener, 0.3 part of defoamer, 0.3 part of fluid It is composed of leveling agent, 1 part of external linking agent and 3.2 parts of water-based color paste. This component is thickened and compounded under the stirring of a disperser, and the viscosity is adjusted to 1980cps / 20°C to become the surface layer slurry for synthetic leather.

[0069] S32: coating the surface layer slurry on a release paper to form a water-based resin surface layer, and drying the water-based resin surface layer. The release paper uses DE90 release paper produced by Warren Company of the United States, the coating thickness is 5 wires, and the transmission speed of the actuator in the first oven is 10m / min.

[0070] S33: configuring middle layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com