Production process of cashmere and marine cell blending yarn

A technology of blended yarn and production process, applied in the field of dyeing and spinning, can solve the problems of poor mixing uniformity, affecting the wide application of cashmere and marine cell fiber blended products, and difference in dyeing fastness, so as to reduce chromatic aberration and reduce pilling. and hairiness, the effect of improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

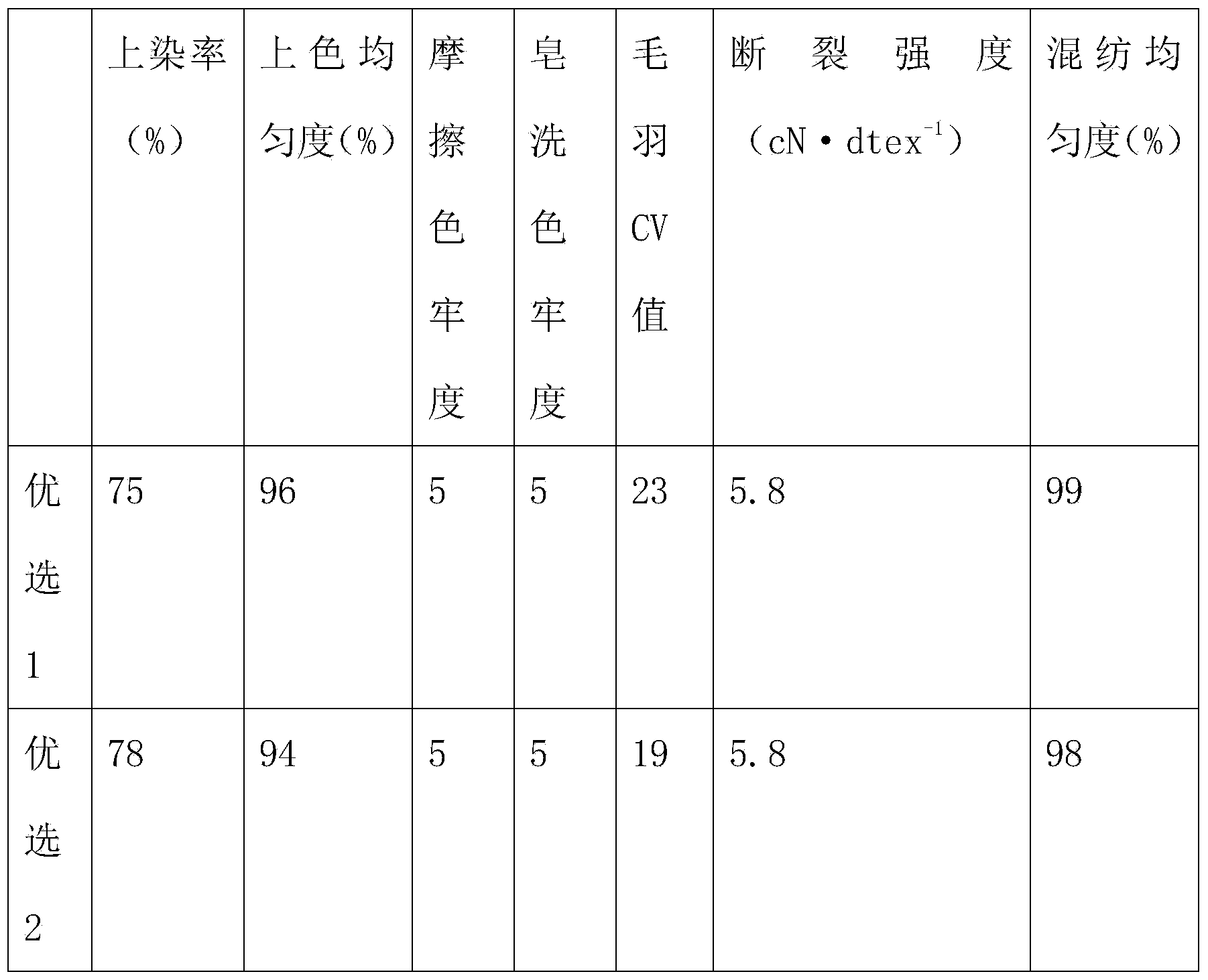

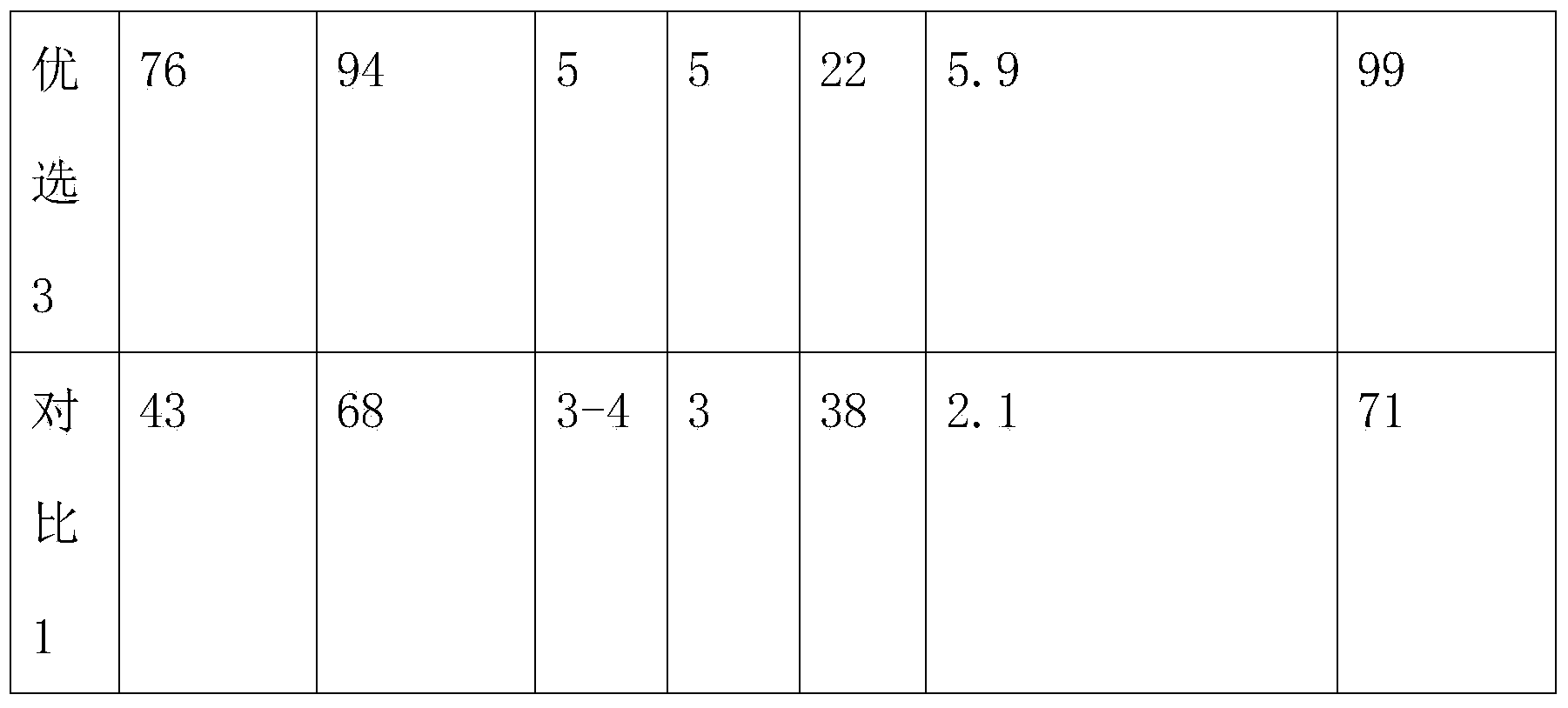

Examples

Embodiment 1

[0039] A kind of production technology of cashmere marine cell blended yarn is characterized in that the steps are as follows:

[0040] The following percentages are mass percentages;

[0041] A. Open

[0042] The cashmere raw material and the marine cell fiber raw material are respectively opened; the beater used for the cashmere raw material is a drum beater, and the beater speed is controlled at 470r / min; the beater used for the marine cell fiber raw material is a porcupine beater, and the beater speed is controlled at 230r / min;

[0043] B. Pretreatment

[0044] Put the cashmere raw material and marine cell fiber raw material treated in step A into acetic acid for acid etching treatment, the pH value is controlled at 4.5, soak for 6 minutes, then take it out and rinse with deionized water for 20 minutes;

[0045] C. Cashmere dyeing

[0046] Put the cashmere raw material into deionized water, control the bath ratio at 1:15, add 2% of alkyl polyoxyethylene ether, 0.09 of s...

Embodiment 2

[0064] A kind of production technology of cashmere marine cell blended yarn is characterized in that the steps are as follows:

[0065] The following percentages are mass percentages;

[0066] A. Open

[0067] The cashmere raw material and the marine cell fiber raw material are respectively opened and loosened. The beater used for the cashmere raw material is a drum beater, and the beater speed is controlled at 550r / min; the beater used for the marine cell fiber raw material is a porcupine beater, and the beater speed is controlled at 300r / min;

[0068] B. Pretreatment

[0069] The cashmere raw material and marine cell fiber raw material processed in step A are put into tannic acid for acid etching treatment, the pH value is controlled at 4.7, soaked for 7 minutes, and then rinsed with deionized water for 20 minutes after taking it out;

[0070] C. Cashmere dyeing

[0071] Put the cashmere raw material into deionized water, control the bath ratio at 1:16, add 2.3% alkyl pol...

Embodiment 3

[0089] A kind of production technology of cashmere marine cell blended yarn is characterized in that the steps are as follows:

[0090] The following percentages are mass percentages;

[0091] A. Open

[0092] The cashmere raw material and the marine cell fiber raw material are respectively opened and loosened. The beater used for the cashmere raw material is a drum beater, and the beater speed is controlled at 630r / min; the beater used for the marine cell fiber raw material is a porcupine beater, and the beater speed is controlled at 330r / min;

[0093] B. Pretreatment

[0094] Put the cashmere raw material and marine cell fiber raw material treated in step A into formic acid for acid etching treatment, the pH value is controlled at 4.2, soak for 8 minutes, then take it out and rinse with deionized water for 20 minutes;

[0095] C. Cashmere dyeing

[0096]Put the cashmere raw material into deionized water, control the bath ratio at 1:17, add 2.7% alkyl polyoxyethylene ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com