A kind of late significantly enhanced cement grinding aid and preparation method thereof

A cement grinding aid and enhanced technology, which is applied in the field of cement grinding aids, can solve the problems of unsatisfactory enhancement effect and insufficient cement enhancement effect, and achieve the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

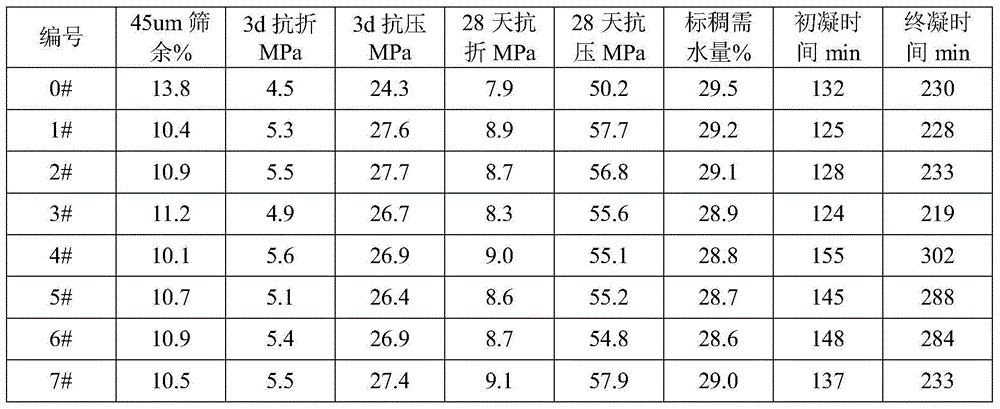

Examples

Embodiment 1

[0019] Each component was weighed according to the following mass percentages: 30% alcohol amine composition, 5% anhydrous sodium sulfate, 2% acetic acid, 15% sodium gluconate, 10% glycerol, 5% molasses, and 33% water. The alcohol amine composition is a mixture of diethanol monoisopropanolamine and polyethylene glycol at a mass ratio of 1:1.

[0020] First add accurately weighed water into the stirring tank, then pour accurately weighed anhydrous sodium sulfate and sodium gluconate into the stirring tank in turn at normal temperature and pressure, and fully stir for 30 minutes, then combine accurately weighed alcohol amines Add acetic acid, glycerin, and molasses into the stirring tank in turn and stir for 30 minutes, then add acetic acid and stir for 30 minutes, then filter to obtain the finished product, number 1#.

Embodiment 2

[0022] Each component is weighed according to the following mass percentage: 20% alcoholamine composition, 5% anhydrous sodium sulfate, 2% acetic acid, 19% sodium gluconate, 15% glycerol, 5% molasses, 34% water, all The alcohol amine composition is a mixture of diethanol monoisopropanolamine and polyethylene glycol at a mass ratio of 1:1.

[0023] First add accurately weighed water into the stirring tank, then pour accurately weighed anhydrous sodium sulfate and sodium gluconate into the stirring tank in turn at normal temperature and pressure, and fully stir for 30 minutes, then combine accurately weighed alcohol amines Add acetic acid, glycerin, and molasses into a stirring tank in turn and stir for 30 minutes. Finally, add acetic acid and stir for 30 minutes. Filter to obtain the finished product, number 2#.

Embodiment 3

[0025] Each component was weighed according to the following mass percentages: 10% alcohol amine composition, 10% anhydrous sodium sulfate, 3% acetic acid, 26% sodium gluconate, 10% glycerol, 10% molasses, 31% water. The alcohol amine composition is a mixture of diethanol monoisopropanolamine and polyethylene glycol at a mass ratio of 1:1.

[0026] First add accurately weighed water into the stirring tank, then pour accurately weighed anhydrous sodium sulfate and sodium gluconate into the stirring tank in turn at normal temperature and pressure, and fully stir for 30 minutes, then combine accurately weighed alcohol amines Pour the mixture, glycerin and molasses into the stirring tank in turn and stir for 30 minutes, then add acetic acid and stir for 30 minutes, then filter to get the finished product, number 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com