Micro-power municipal sewage treatment equipment and process

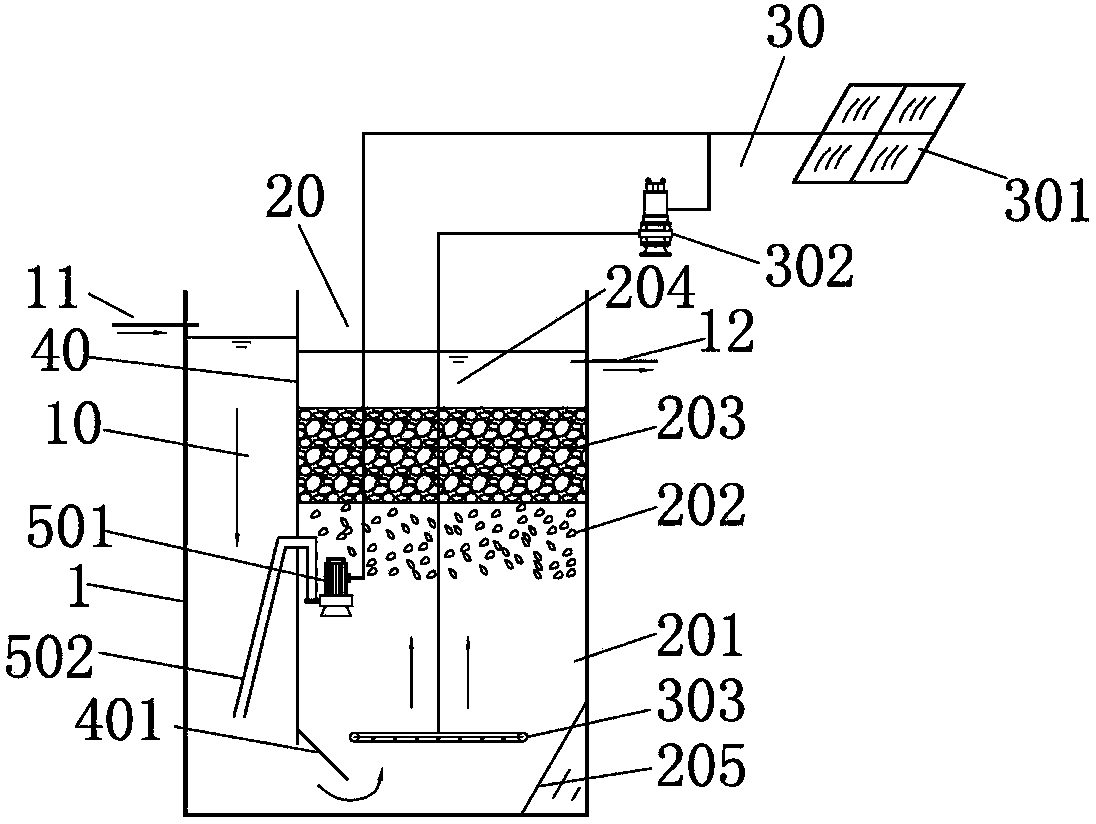

A township sewage and treatment equipment technology, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, energy wastewater treatment, etc., can solve problems such as inconvenient maintenance, high operating costs, and large floor space, and achieve Low concentration of suspended solids in effluent, improved treatment efficiency, and enhanced treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

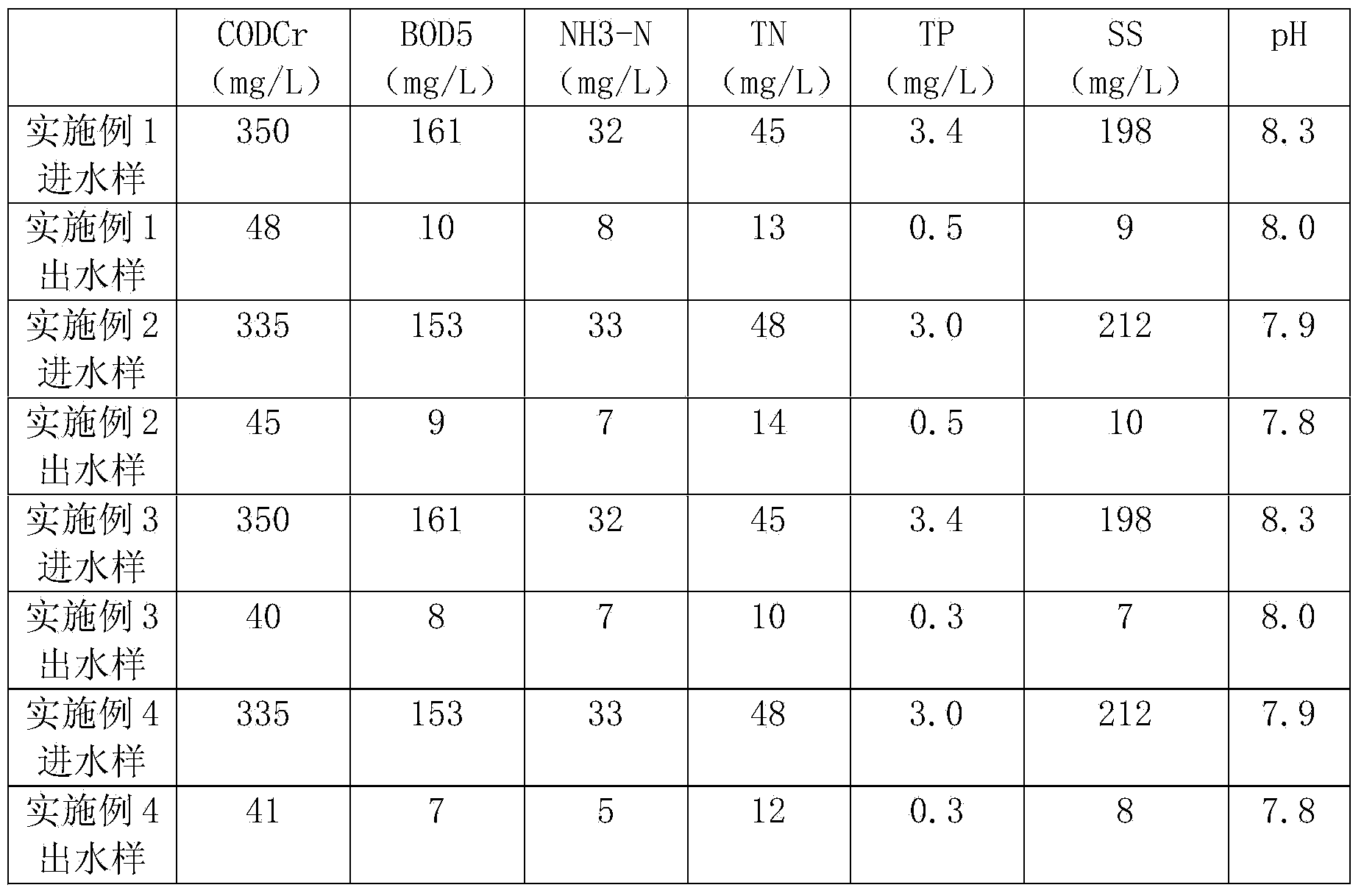

[0034] Taking the sewage treatment of a certain township as an example, the micro-dynamic sewage treatment equipment and process of the present invention are used for treatment. Under normal operation, the water quality of the influent and effluent water is shown in the table below, wherein the influent samples of embodiment 1 and embodiment 3 are the same. The water inlet sample of example 2 and embodiment 4 is identical, and the used sewage treatment equipment of embodiment 1, embodiment column 2 and embodiment 3, embodiment 4 is the micro power sewage treatment equipment of the present invention, and the processing time is identical, but Embodiment 1 and Example 2 used common suspension fillers, and the suspension fillers used in Embodiment 3 and Example 4 were suspension fillers prepared from components described in the present invention.

[0035] It can be seen from the table below that the effluent water quality fully meets the first-class A standard in the "Pollutant Dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com