A kind of ceramic spring forming device and preparation method of ceramic spring

A spring forming and forming device technology, which is applied in the field of ceramic springs, can solve problems such as material defects and irregular shapes, and achieve the effects of reducing reliability in use, fewer defects, and improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

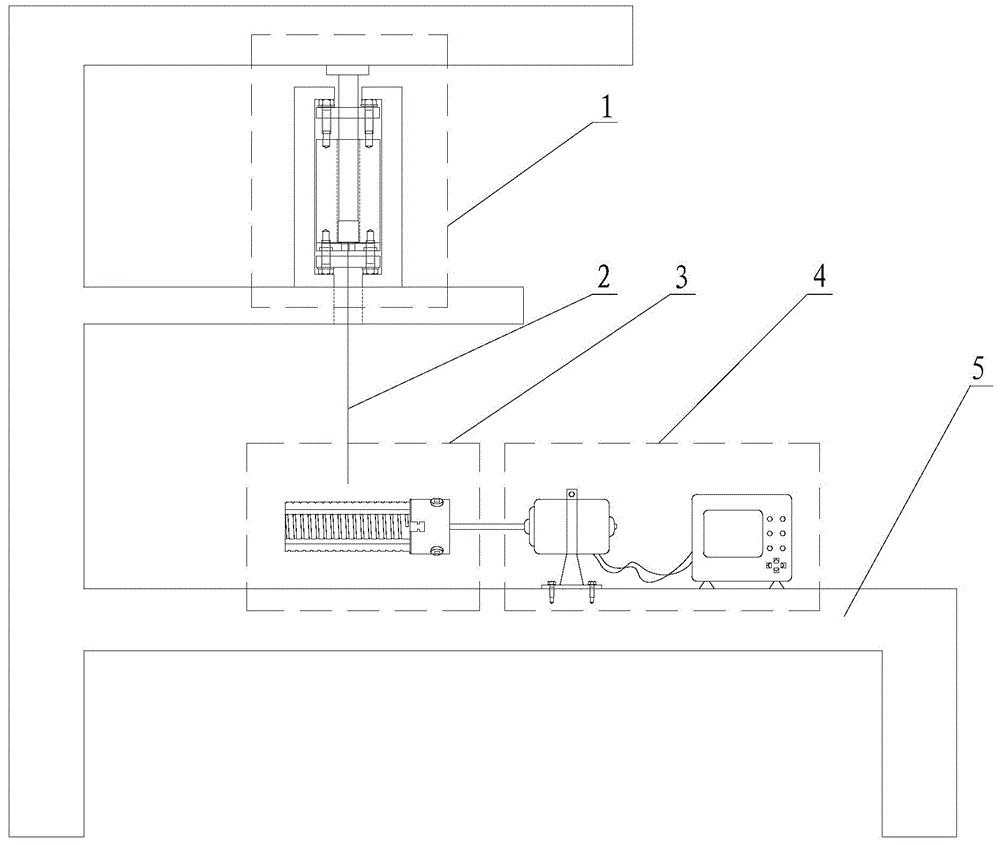

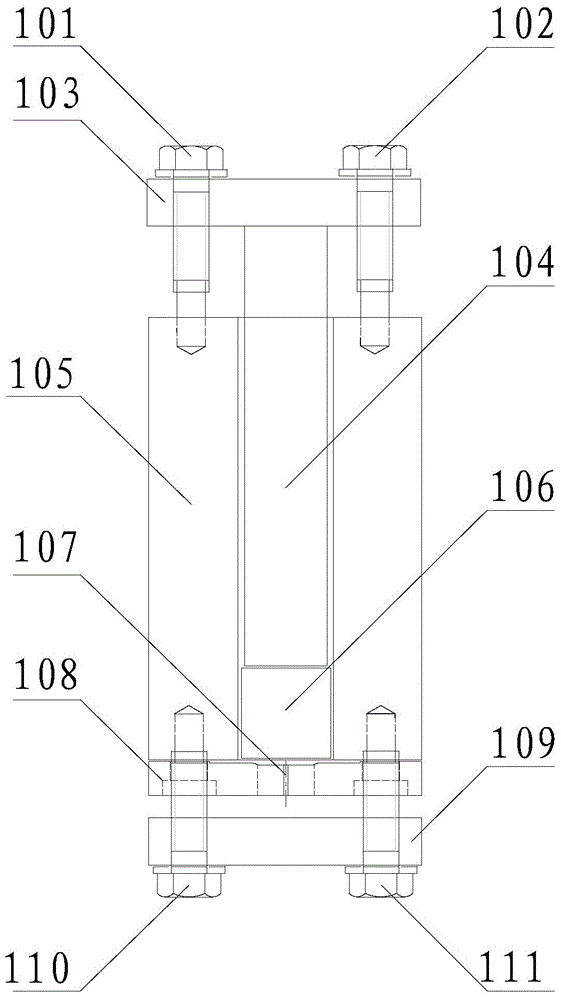

[0058] 1) To obtain continuous polycarbosilane filaments: take 50 g of solid polycarbosilane, and then put it into the barrel 105 of the melt spinning forming device. After assembly, put the melt spinning forming device 1 into the vacuum furnace, and set the temperature rise Rise from room temperature to 200°C in 100 minutes, then rise from 200 to 300°C in 100 minutes, keep warm for 3 hours, take out the melt spinning molding device after natural furnace cooling, put it into a small melt spinning machine immediately, and set the spinning temperature to 280°C , and then spray polycarbosilane filaments 2.

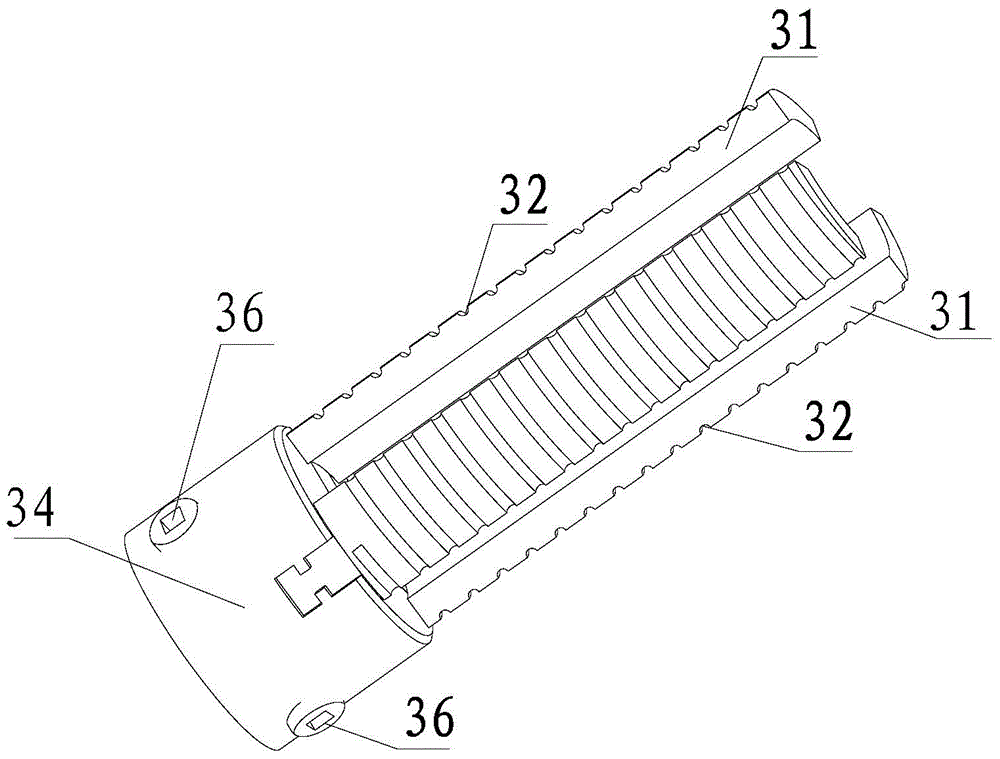

[0059] 2) Polycarbosilane spring winding molding: use a voltaic wrench to rotate the small bevel gear 36, adjust the outer diameter of the cylinder formed by the three arc-shaped clamping plates 31 to 20mm, and install it on the motor 41 whose speed is set at 20 rpm On, use tweezers to pull the continuous polycarbosilane filament 2 to the arc groove 32 of the arc-shaped clamp...

Embodiment 2

[0065] 1) To obtain continuous polyaluminocarbosilane filaments: take 50 g of solid polyaluminocarbosilane, and then put it into the barrel 105 of the melt-spinning forming device. After assembly, put the melt-spinning forming device 1 into the vacuum furnace, and set The temperature rise program takes 100 minutes to rise from room temperature to 200°C, and then takes 100 minutes to rise from 200 to 340°C, keep warm for 3 hours, take out the melt spinning forming device 1 after natural furnace cooling, immediately put it into a small melt spinning machine, and set the spinning temperature to 320°C, and then spray polyaluminocarbosilane filaments 2.

[0066] 2) Polyaluminocarbosilane spring winding molding: use a voltaic wrench to rotate the small bevel gear 36, adjust the outer diameter of the cylinder formed by the three arc-shaped clamping plates 31 to 20mm, and install it on the motor 41 whose speed is set at 20r / min First, use tweezers to pull the continuous polyaluminocar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com