A tool for machining the blade hole of the impeller body of the axial flow pump

A technology for pump impellers and processing shafts, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve problems such as concentricity, achieve accurate graduations, and solve the effects of measuring benchmark problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

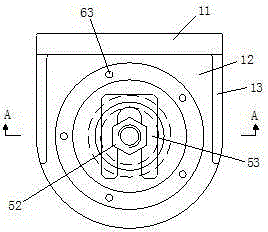

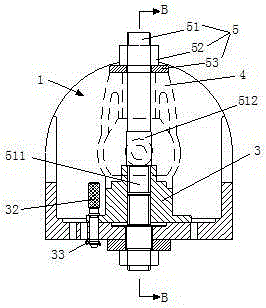

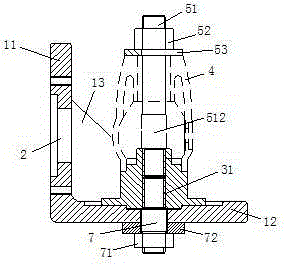

[0018] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 The shown tooling for machining the blade holes of the impeller body of an axial flow pump includes a rotary body 1 fixed to the main shaft of a lathe, and the rotary body 1 is composed of a first plate 11 and a second plate 12 arranged in an L shape. The first plate 11 and the second plate 12 are castings formed by integral casting. The first plate 11 is provided with a first notch 2 matched with the main shaft of the lathe, and the center position of the second plate 12 is fixed with an indexing block 3. A fastening device 5 for fixing the workpiece 4 on the indexing block 3 is provided above the indexing block 3, and the outer side of the indexing block 3 is provided with first, second, third Layer positioning pin holes, the first layer of positioning pin holes include three first pin ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com