Stable pressing cutter mechanism, high-precision magnet loading device and operating method thereof

A loading device and high-precision technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems such as reduction, achieve the effects of improving machining accuracy, ensuring coaxiality, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

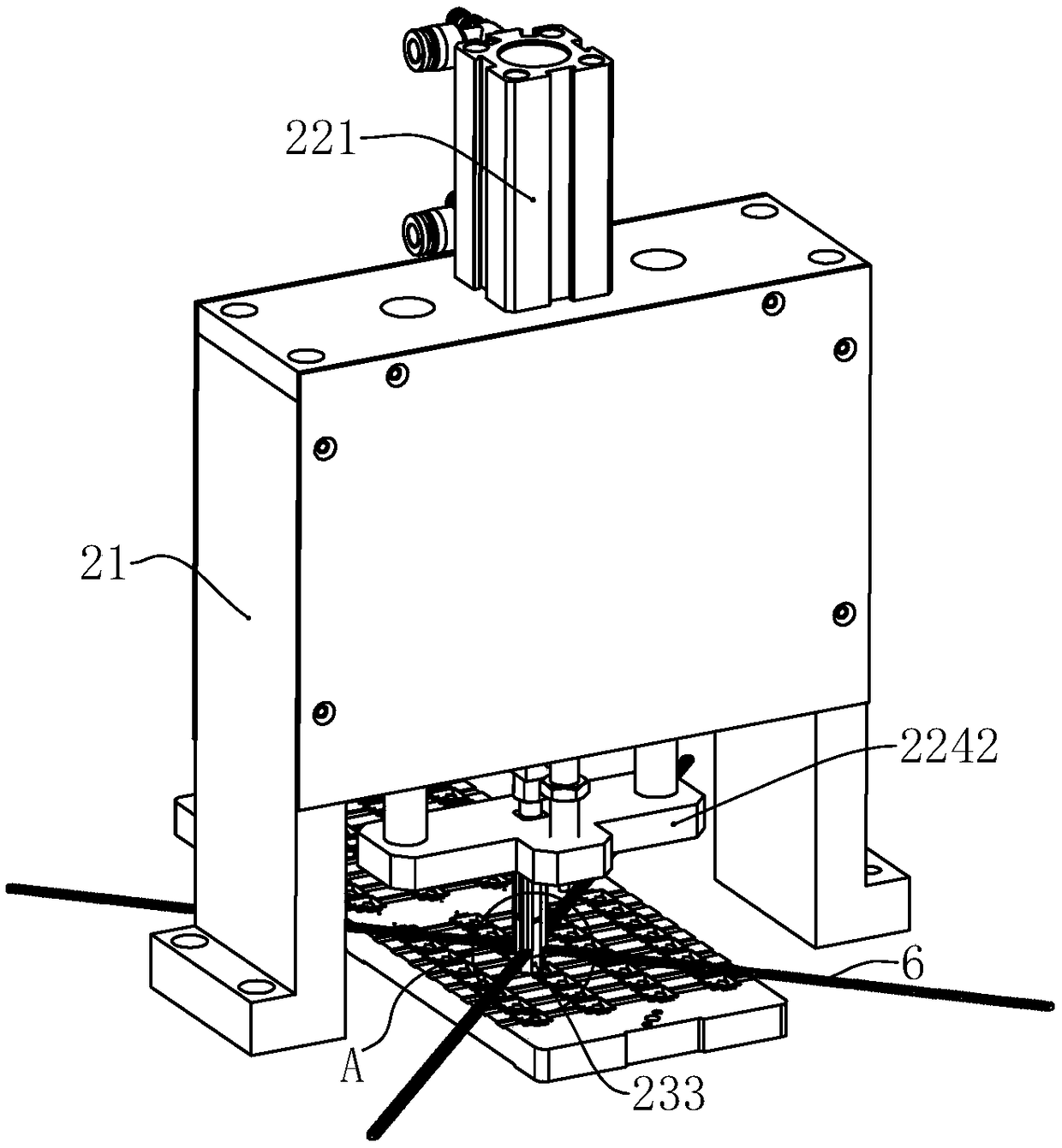

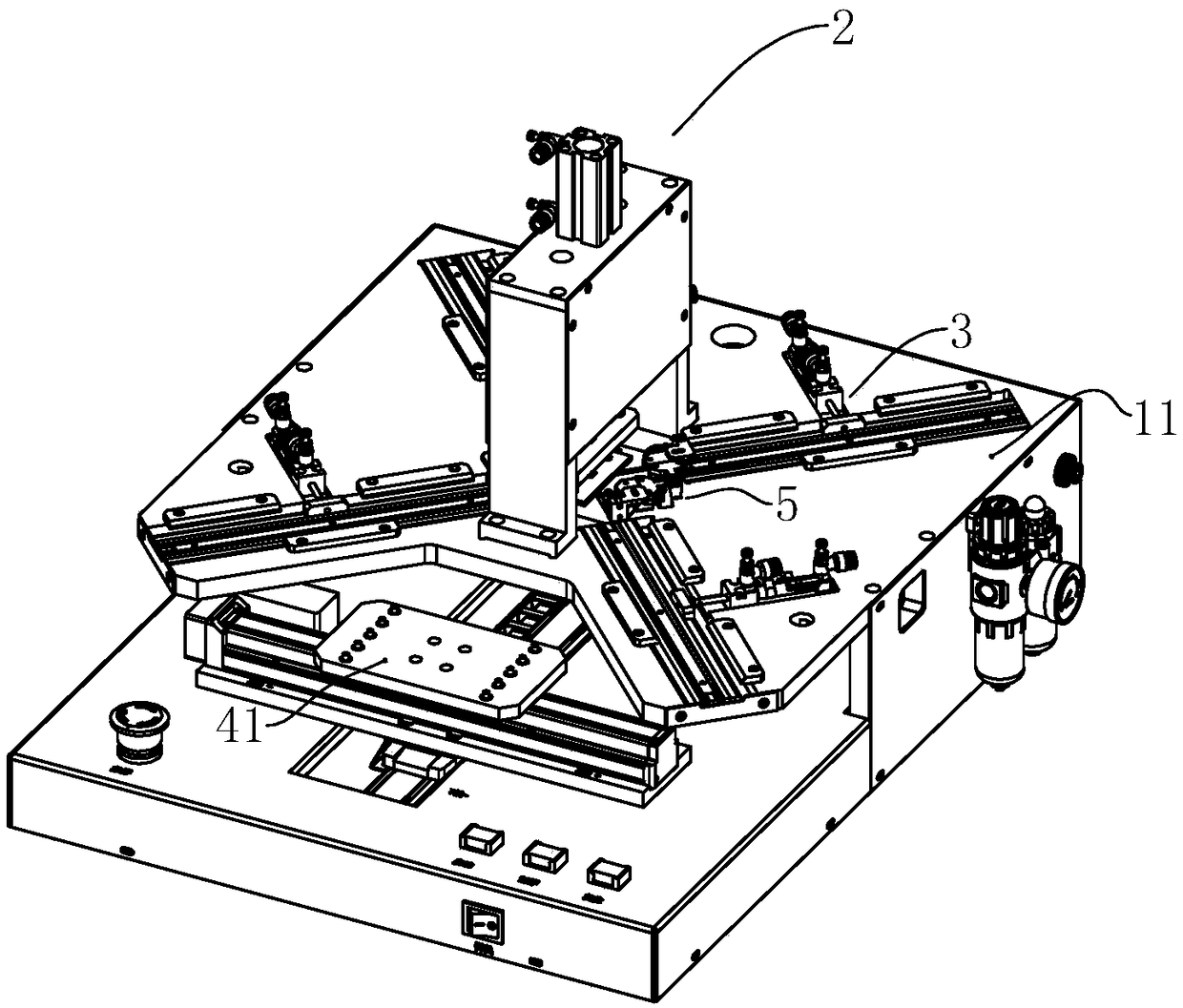

[0064] Such as Figure 1-5 As shown, a high-precision magnet loading device includes a workbench 11, a magnet press-in mechanism 2 installed on the workbench 11, a magnet feeding mechanism 3 arranged on the workbench 11, and a jig arranged below the workbench 11. 41.

[0065] A notch is provided on the workbench 11 to facilitate the replacement of the jig 41 .

[0066] The magnet press-in mechanism 2 includes a gantry frame 21, which is arranged above the center position of the workbench 11, on the gantry frame 21 is provided with a pressing knife assembly that moves up and down intermittently, and the pressing knife assembly includes a vertically arranged and The iron core 233 for absorbing the magnet and the pressure sleeve 224 socketed with the iron core 233, the pressure sleeve 224 includes four pressure strips 2241 evenly distributed on the side wall of the iron core 233 and not attracted to the magnet, and the connection There are four beading bars 2241 and a beading b...

Embodiment 2

[0087] Compared with Embodiment 1, this embodiment differs in the pressing knife assembly, the second driving mechanism and the working method.

[0088] In Embodiment 1, the iron core 233 is installed on the piston rod of the second cylinder 231 through the connector 232, so the rotation of the piston rod will directly cause the iron core 233 to rotate, and it is difficult for the magnet press knife and the guide iron core to ensure both The coaxiality between them will easily cause the wear of the pressing knife or the iron core, reduce the life of the part, and at the same time, it is prone to the phenomenon of magnetism. In order to solve these problems, we designed a stable pressure knife mechanism that can simultaneously ensure the coaxiality of the iron core and the pressure and prevent the iron core from rotating at the working position.

[0089] Such as Figure 12 ~ Figure 13 As shown, the stabilizing knife pressing mechanism includes a lower beam 25 , a second drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com