Railway vehicle side wall welding process equipment system

A rail vehicle side wall and welding process technology, applied in the field of rail vehicle side wall welding process equipment system, can solve the problems of reduced production efficiency, occupation of workshop space, waste of workshop space, etc., to improve production efficiency, avoid coexistence, and universality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

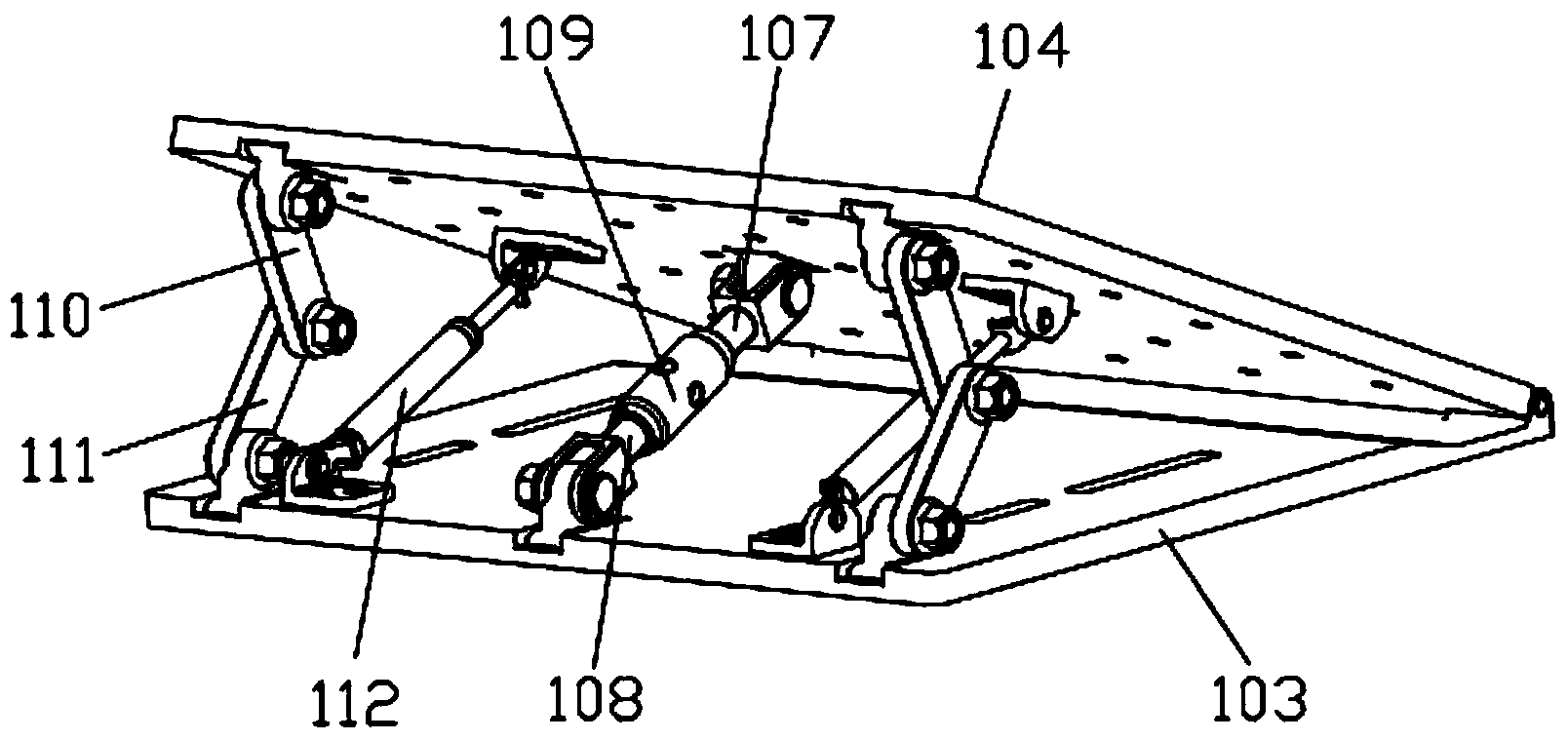

[0019] Please refer to figure 1 and figure 2 , the embodiment of the present invention provides a rail vehicle side wall welding process equipment system, including: a platform 101 for carrying a side wall workpiece 201; an adjustment device 102, including a mounting plate 103, the bottom of which is used for connecting with the The upper surface of the platform 101 is detachably connected, the first end of the mounting plate 103 is hinged with the end of the adjusting plate 104 through a horizontal pin, and a driving device is arranged between the mounting plate 103 and the adjusting plate 104, and the driving device It is used to drive the adjusting plate 104 to rotate relative to the mounting plate 103 in the vertical plane; the upper pressing mechanism 105 is used to compress one end of the side wall workpiece 201, and the bottom of the upper pressing mechanism 105 Used to be detachably connected to the upper surface of the platform 101 or the upper surface of the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com