Zero-emission treatment system and method of epoxy ethane

An ethylene oxide, zero-emission technology, applied in separation methods, chemical instruments and methods, chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

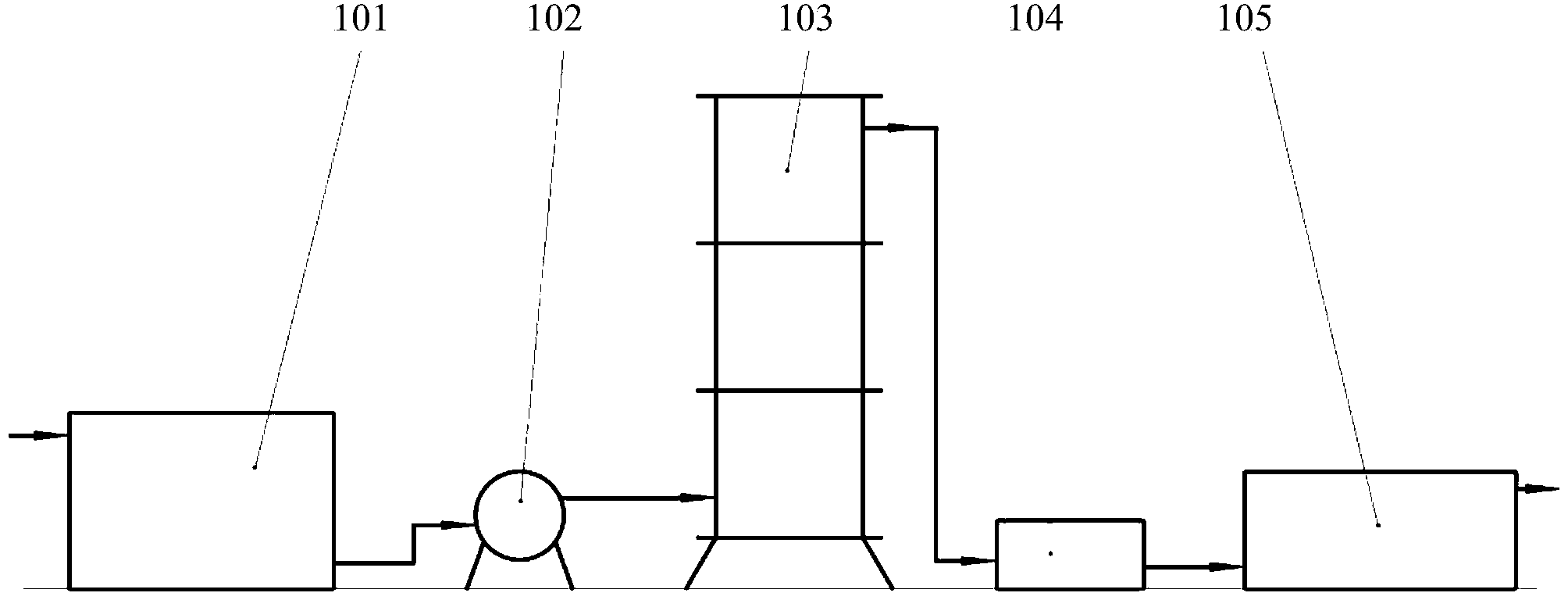

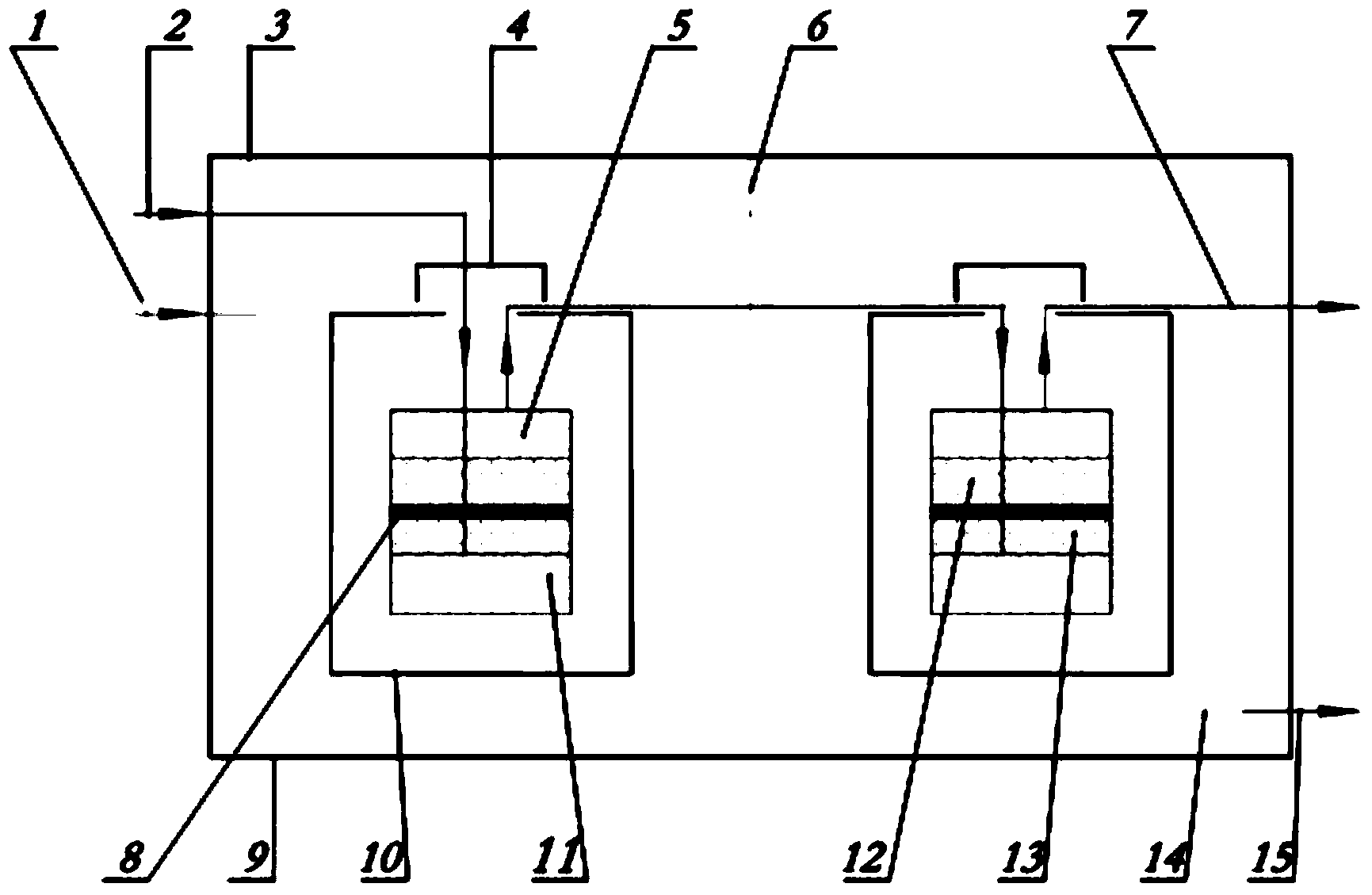

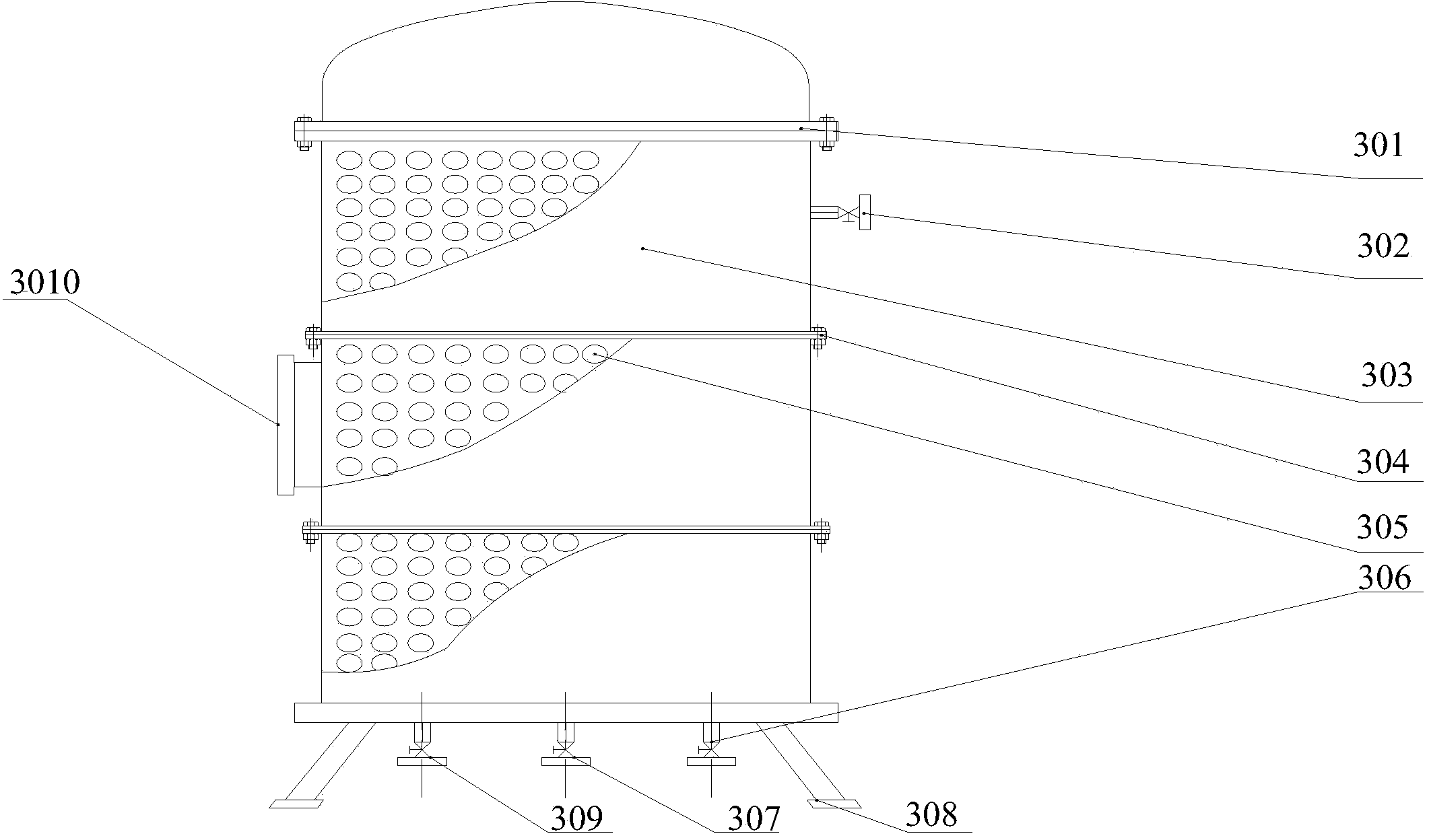

[0099] see figure 1 , figure 2 , image 3 , an ethylene oxide waste gas combination treatment device, including an air pump, a combiner 101, a gas-liquid pump 102, a turbulent ball tower 103 and a disperser 104;

[0100] The air pump is connected with the air inlet 2 of the combiner 101, and transports ethylene oxide waste gas to the combiner;

[0101] The combiner 101 includes a combiner box 9, a plurality of parallel reactors 10 are arranged in the combiner box 9, and the gas pipe inlet connected with the air inlet 2 is arranged at the bottom of the reactor 10, and in the reactor 10 Filled with sulfonated reactants, a gas-assisted reaction device is provided on the way of gas dissipating upwards, the outlet of the gas pipe is set on the upper surface of the reactor and connected with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Volume index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com