Antimony pentafluoride rectification equipment

An antimony pentafluoride essence and equipment technology, applied in the field of rectification, can solve the problems of increasing antimony pentafluoride impurities, slowing product purity, accelerating corrosion rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

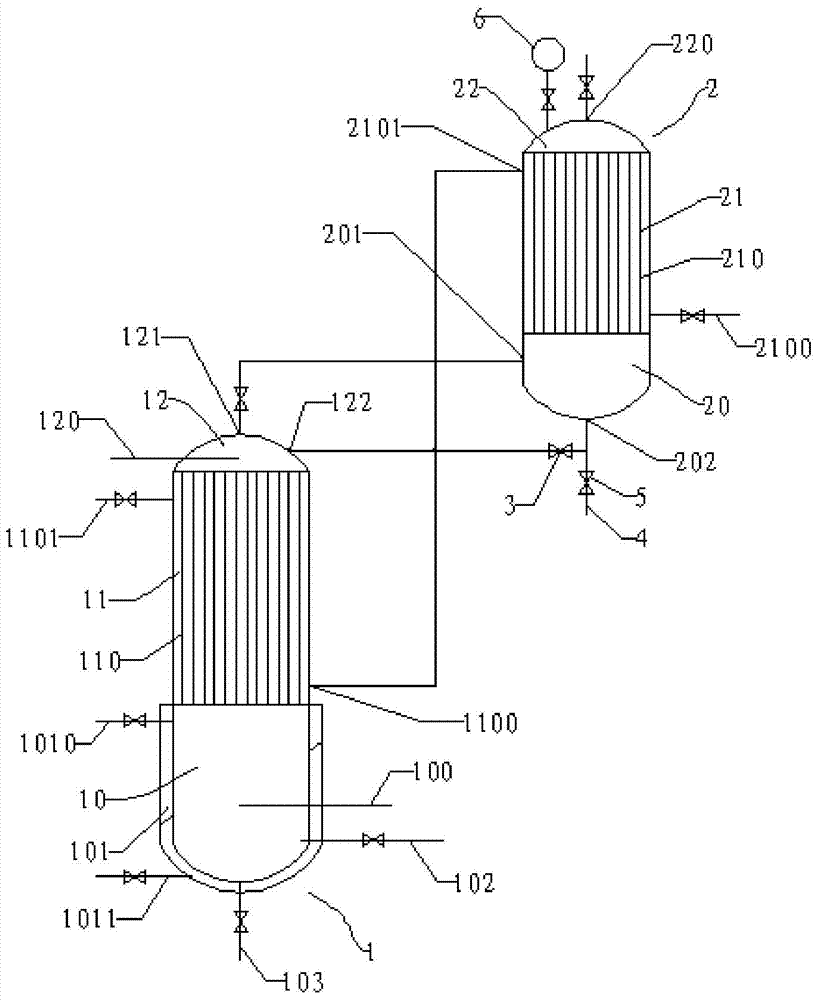

[0032] see figure 1 As shown, the antimony pentafluoride rectification equipment of this embodiment includes a distillation condenser 1 and a recovery condenser 2;

[0033] The distillation condenser 1 includes a heating zone 10, a first condensation zone 11, and a temperature control zone 12 from bottom to top. The heating zone 10 is provided with a temperature measuring rod 100, and the heating zone 10 is provided with a steam heating clamp. cover 101, the side of the heating zone 10 is provided with a material inlet 102, the bottom of the heating zone 10 is provided with a slag removal port 103, the first condensation zone 11 is provided with a first cooling tube 110, and the temperature A temperature sensor 120 is provided in the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com