Cortex moutan microcapsule for treating allergic dermatitis, and preparation method and application thereof

A technology of allergic dermatitis and microcapsules, which is applied in the application field of fabrics, can solve the problems of short drug effect time, etc., and achieve the effect of simple preparation process, mild preparation conditions, and enhanced therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

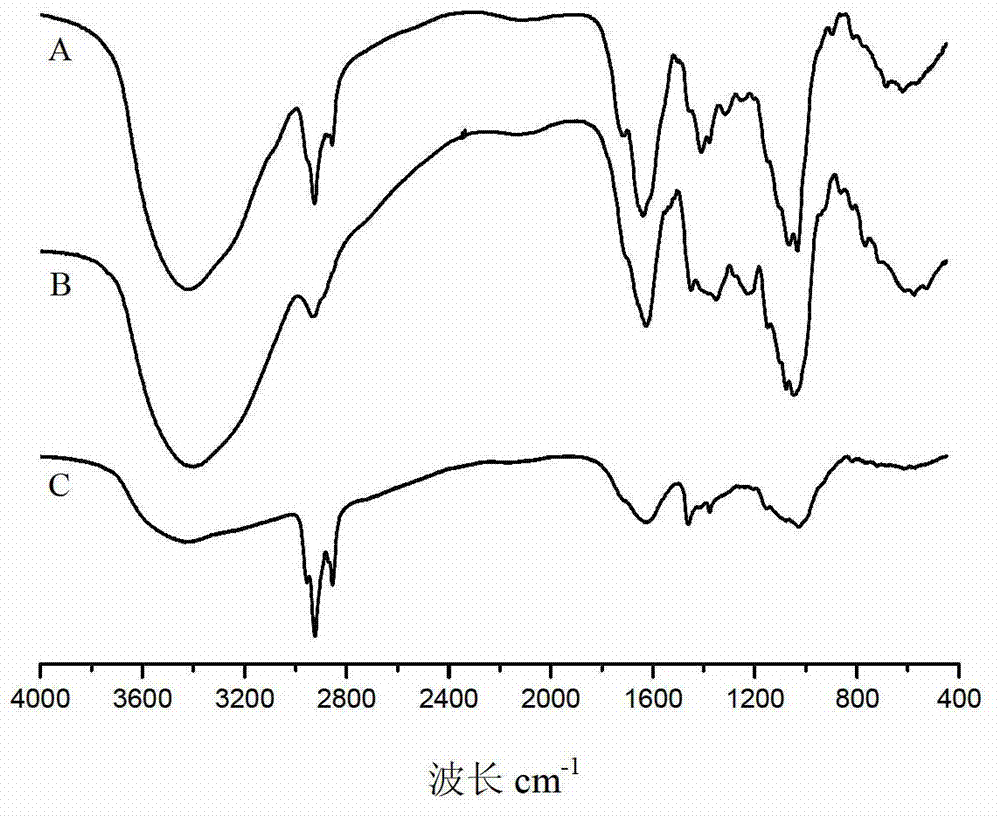

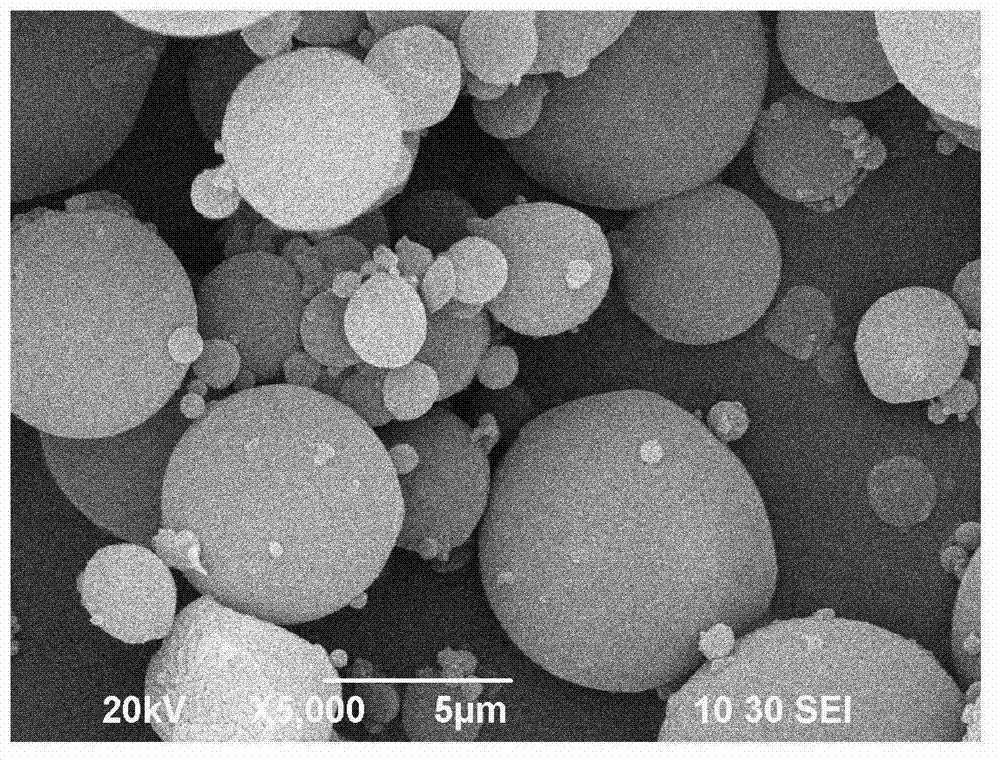

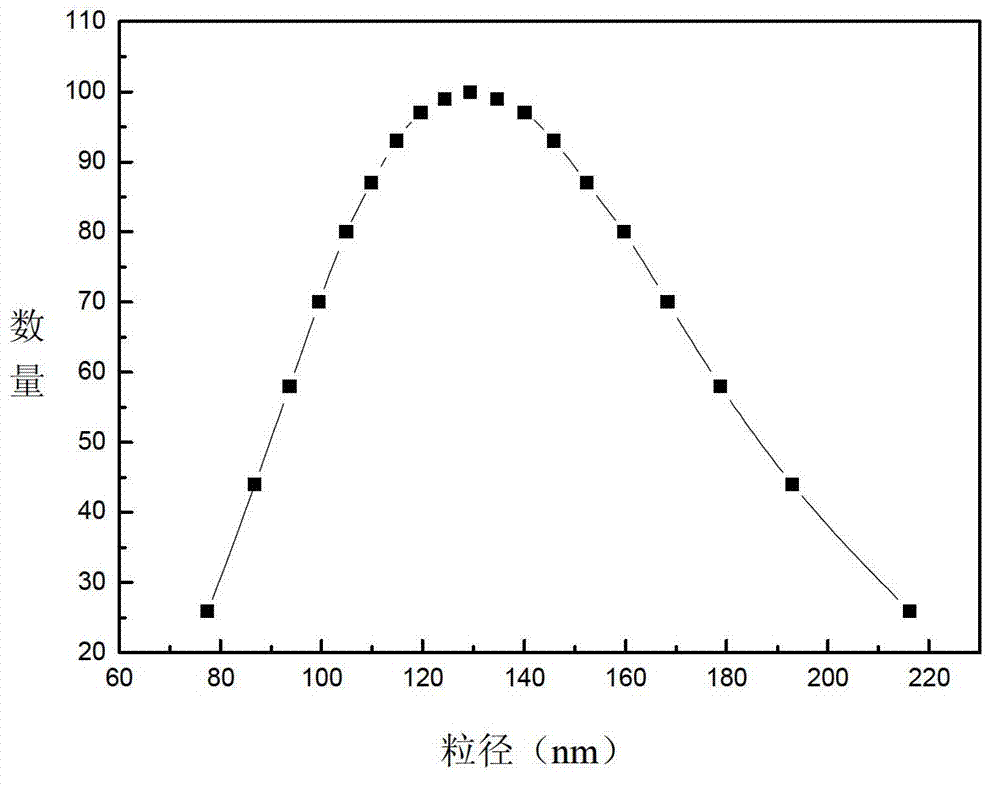

[0030] 0.5 g of chitosan was dissolved in 25 ml of 2% acetic acid solution and stirred until completely dissolved to obtain chitosan acetic acid solution. 1.0g paeonol powder was uniformly dispersed in 25ml deionized water by ultrasonic dispersion, then 0.5g sodium alginate was added to it, and stirred at a high speed at 1000rpm until the sodium alginate was completely swollen. Then, the prepared chitosan acetic acid solution was added therein, and stirred at a high speed at 1000 rpm until the system was uniformly dispersed to obtain a ready-to-use mixture. At the same time, add 300ml of liquid paraffin in the three-necked flask, and add surfactant Span 80 to make its content reach 2%. Heat the mixture of liquid paraffin and Span 80 in a water bath at 100°C. When the temperature rises to 55°C, add the dispersed mixture. Stir at a high speed of 1000 rpm for 20 minutes, then stop heating and cool down with an ice bath. When the temperature drops below 10°C, use 5% NaOH solutio...

Embodiment 2

[0032] 1.25g of chitosan was dissolved in 50ml of 2% acetic acid solution, stirred until completely dissolved to obtain chitosan acetic acid solution. 0.5g of paeonol powder was uniformly dispersed in 25ml of deionized water by ultrasonic dispersion, then 1.0g of sodium alginate was added to it, and stirred at a high speed at 1000rpm until the sodium alginate was completely swollen. Then, the prepared chitosan acetic acid solution was added therein, and stirred at a high speed at 1000 rpm until the system was uniformly dispersed to obtain a ready-to-use mixture. At the same time, 450ml of liquid paraffin was added in a three-necked flask, and a mixture of Span 80 and Tween 80 in a ratio of 1:1 was added to make its content reach 2%. Heat the mixture of liquid paraffin, Span 80 and Tween 80 in a water bath at 100°C, and add the dispersed mixture when the temperature rises to 60°C. Stir at a high speed of 800 rpm for 25 minutes, then stop heating and cool down with an ice bath....

Embodiment 3

[0034] 0.2 g of chitosan was dissolved in 12 ml of 2% acetic acid solution and stirred until completely dissolved to obtain chitosan acetic acid solution. 1.0g paeonol powder was uniformly dispersed in 24ml deionized water by ultrasonic dispersion, then 1.0g sodium alginate was added thereto, and stirred at a high speed at 1200rpm until the sodium alginate was completely swollen. Then, the prepared chitosan acetic acid solution was added therein, and stirred at a high speed at 800 rpm until the system was evenly dispersed to obtain a ready-to-use mixture. Meanwhile, add 252ml liquid paraffin in the there-necked flask, and add surfactant Span 80, make its content reach 2%. Heat the mixture of liquid paraffin and Span 80 in a water bath at 100°C. When the temperature rises to 65°C, add the dispersed mixture. Stir at a high speed of 1000 rpm for 30 minutes, then stop heating and cool down with an ice bath. When the temperature dropped below 10°C, use 5% NaOH solution to adjust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com