A new type of front electrode for crystalline silicon solar cells

A solar cell, front electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of easy generation of microcracks or fragments, unable to continue to collect current, lack of flexibility of silicon, etc., to improve anti-oxidation performance, open circuit Effects of reduced voltage and series resistance and increased fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

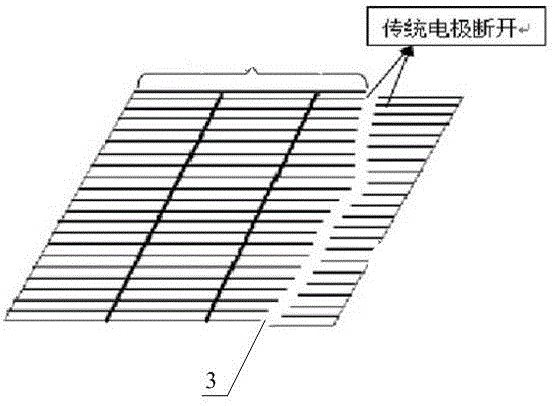

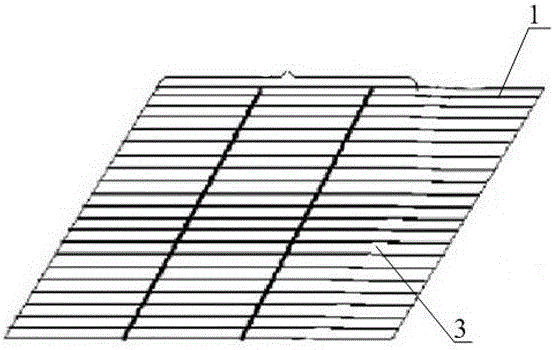

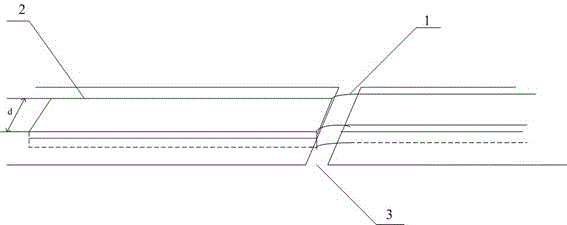

[0013] Accompanying drawing is a kind of specific embodiment of the present invention. The novel front electrode of the crystalline silicon solar cell is characterized in that: the novel front electrode 1 is located in the groove 2 of the n-type surface of the crystalline silicon cell, and is a Cu-Ag-Ni low-silver conductive alloy electrode, with copper as the substrate, Silver and nickel are used as additional elements, and the width d of the groove 2 is 45 μm, which is only three-quarters of the width of the traditional electrode; the groove 2 is prepared by laser, and the depth of the laser is determined according to the square resistance of the n-type layer. The new front electrode 1 is buried inside the n-type layer, which increases the area for receiving current and reduces the bulk resistance; the Cu-Ag-Ni series low-silver conductive alloy electrode is prepared by electroless plating, and the prepared new front electrode 1 Since the physical strength is improved and no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com